Method for preparing tetraethyl methylenediphosphonate

A technology of tetraethyl methylene diphosphonate and diethyl phosphite, which is applied in the field of preparing tetraethyl methylene diphosphonate, can solve the problem of not being the optimal choice for safety and economy, equipment and operation requirements higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

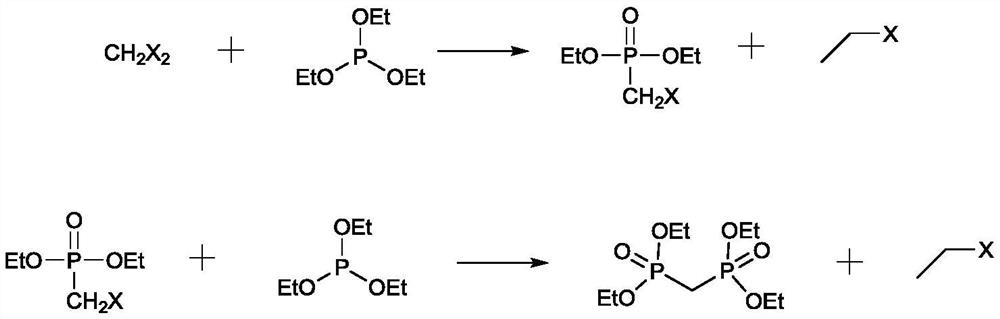

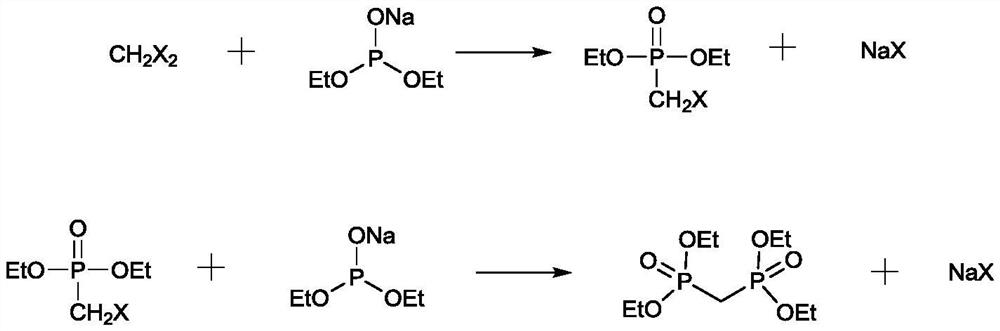

Method used

Image

Examples

specific Embodiment approach

[0056] According to a particularly preferred embodiment of the present invention, the method comprises:

[0057] (1) Under protective atmosphere conditions, sodium methoxide is placed in a three-necked flask, and an organic solvent is added for the first mixing to obtain the first mixed solution. The first mixed solution and the phosphorous acid in terms of contained sodium methoxide The molar ratio of diethyl ester is 9-4:1;

[0058] (2) At 15-35°C, add diethyl phosphite dropwise to the first mixed solution, and after dropping, keep warm at a temperature of 15-60°C for 6-12h for the second mixing to obtain diethyl phosphite For the second mixed solution of sodium, the molar ratio of the first mixed solution and the diethyl phosphite in terms of sodium methoxide is 1-1.2:1;

[0059] (3) Distilling the sodium diethyl phosphite solution, the conditions of the distillation treatment include: the pressure is 0-0.095MPa, and the temperature is 10-60°C to remove methanol by-product...

Embodiment 1

[0069] (1) Under the condition of nitrogen protection, weigh the sodium methoxide solid (55g) and place it in a 1000ml three-neck flask, add 260g of absolute ethanol for the first mixing to obtain the first mixed solution;

[0070] (2) Add diethyl phosphite (1 mol, purchased from Sinopharm Reagent Company, the same below) to the first mixed solution at 15°C, control the reaction temperature to 20°C, and keep warm at 20°C for 11h for the second mixing to obtain Sodium diethyl phosphite solution (the second mixed solution);

[0071] (3) The sodium diethyl phosphite solution is subjected to distillation treatment, and the conditions of the distillation treatment include: at a vacuum degree of 0.07MPa, at a temperature of 30° C., decompression distillation to remove solvent, residual diethyl phosphite and steps (2) the methyl alcohol that generates obtains 1mol sodium diethyl phosphite solid;

[0072] (4) At 30°C, add dichloromethane (4mol) dropwise to the three-necked flask cont...

Embodiment 1A

[0074] Adopt the method similar to Example 1, difference is: in step (1), the consumption of the dehydrated alcohol solvent used is different, specifically: the consumption of dehydrated alcohol solvent is 100g;

[0075] The rest were the same as in Example 1 to obtain 173.2 g of tetraethyl methylene diphosphonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com