Ceramizable resin material as well as preparation method and application thereof

A technology of resin materials and ceramization, applied in the field of ceramizable resin materials and their preparation, to achieve the effects of improving weather resistance, excellent flame retardancy, and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

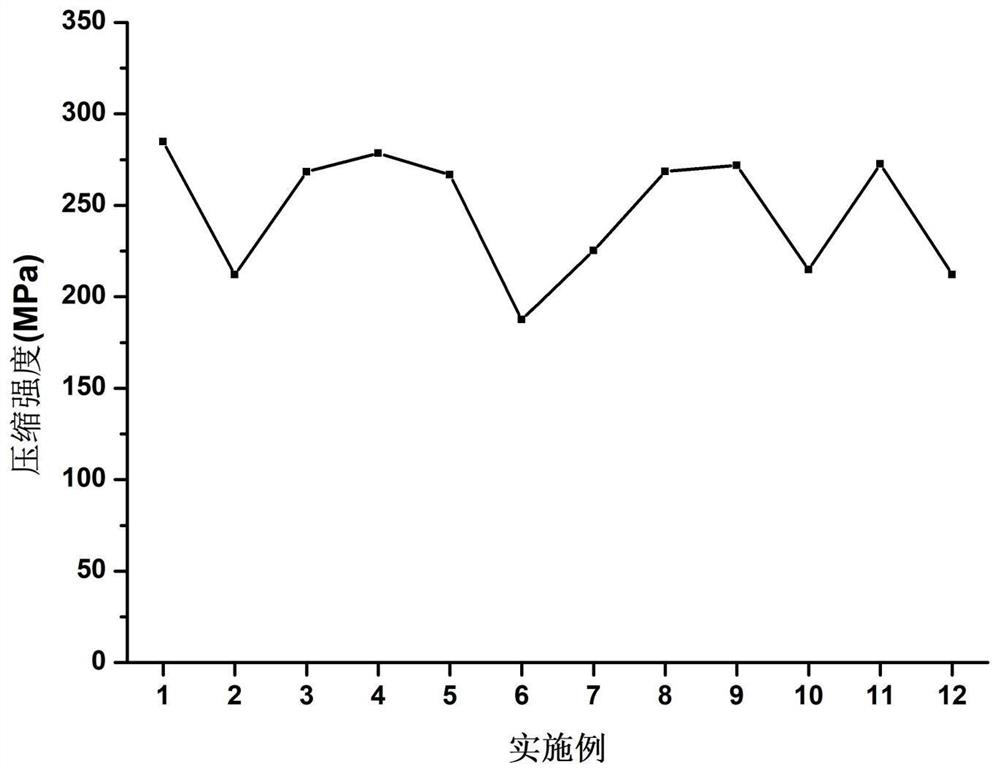

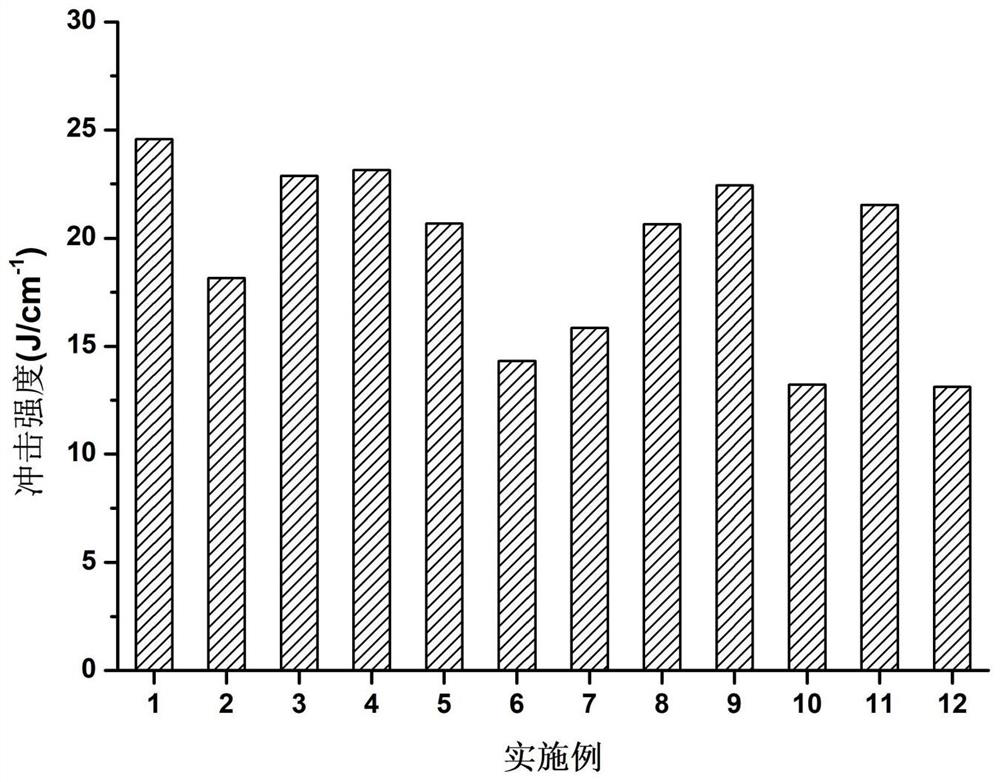

Examples

Embodiment 1

[0048] Embodiment 1: A kind of ceramizable resin material:

[0049] This embodiment provides a ceramizable resin material, comprising: 100 parts by weight of modified epoxy resin, 30 parts by weight of glass powder, 40 parts by weight of wollastonite, 5 parts by weight of methyltetrahydrophthalic anhydride, light-burned magnesium oxide 35 parts by weight of powder, 14.7 parts by weight of modified grossular garnet powder; that is, the weight ratio of modified grossular garnet powder and lightly burned magnesia powder is 0.42:1;

[0050] The ceramizable resin material is prepared by the following method:

[0051] 1) Prepare modified epoxy resin:

[0052] Bisphenol A epoxy resin (epoxy value 0.52mol / 100g) is mixed with N-methyl-2-(2-aminoethyl)-pyrrolidine according to the molar ratio of 1:0.65, stirred evenly at room temperature, and the stirring speed is 200r / min, heat up to 95°C at a rate of 8°C / min, continue to stir for 1h, then add 4,4-diaminodiphenylmethane of 42% of the...

Embodiment 2

[0060] Example 2: Another ceramizable resin material:

[0061] This example provides another ceramizable resin material. The components and preparation method are basically the same as in Example 1, except that in this example, in the process of preparing the modified epoxy resin, the bisphenol A ring The mixing molar ratio of oxygen resin (epoxy value 0.52mol / 100g) to N-methyl-2-(2-aminoethyl)-pyrrolidine is 1:0.3.

Embodiment 3

[0062] Example 3: Another ceramizable resin material:

[0063] This embodiment provides another ceramizable resin material. The components and preparation method are basically the same as in Example 1, except that in the process of preparing modified epoxy resin in this embodiment, bisphenol A epoxy The mixing molar ratio of resin (epoxy value 0.52mol / 100g) to N-methyl-2-(2-aminoethyl)-pyrrolidine is 1:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com