Hydrophobic material for insulin syringe and processing and forming method of material

A hydrophobic material and syringe technology, applied in the field of medical materials, can solve the problems of raw material waste, increased workload and cost, and achieve the effects of saving raw materials, improving automation, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: A kind of processing molding method of insulin syringe:

[0080] This embodiment provides a method for processing and molding hydrophobic materials for insulin syringes, including:

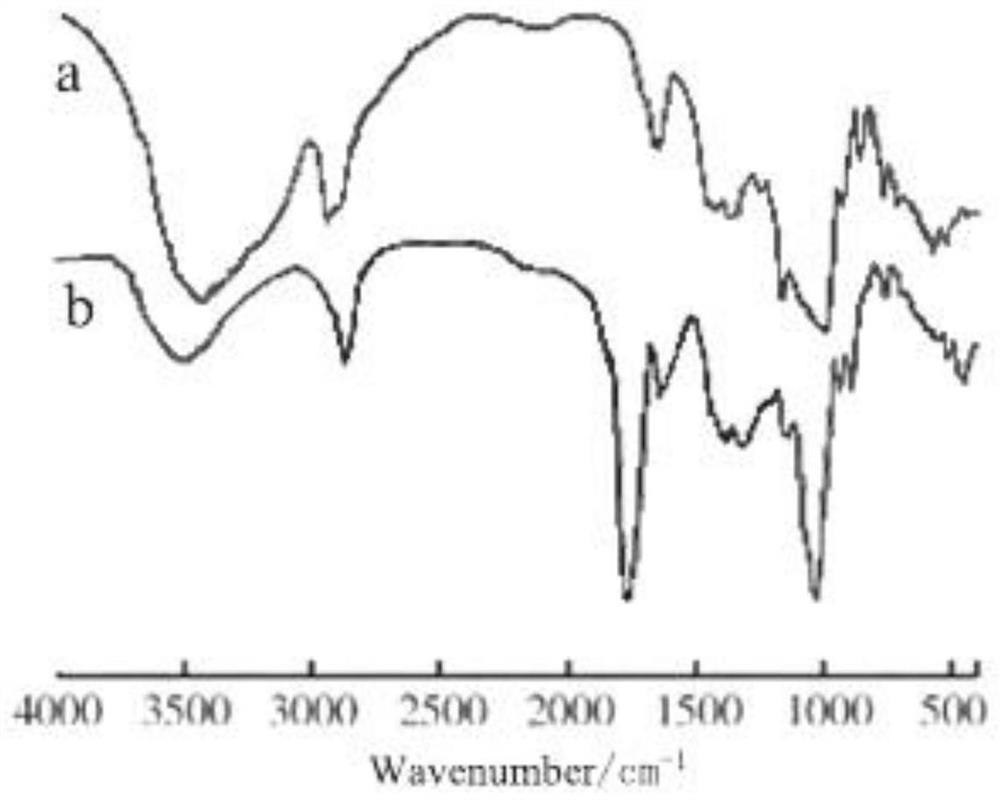

[0081] 1) Preparation of p-hydroxybenzoic acid modified starch:

[0082] 20kg of p-hydroxybenzoic acid was dissolved in 4L of distilled water to form a hydroxybenzoic acid solution, and the pH of the solution was adjusted to 3.5 with 1mol / L sodium hydroxide solution; 40kg of cornstarch (molecular weight 80000) was added to the p-hydroxybenzoic acid solution , ultrasonic (frequency is 20kW, power density is 0.3W / cm 2 ) for 40 minutes, left standing at room temperature for 14 hours, and then dried in a 60°C oven for 5 hours until the solid content was greater than 90%; then the product was ball milled for 20 minutes at a ball milling rate of 300r / min, and reacted at 130°C for 8 hours. The product was washed with deionized water to remove unreacted p-hydroxybenzoic acid, and dr...

Embodiment 2

[0095] Example 2: Another processing method for insulin syringes:

[0096]This example provides another method for processing and molding hydrophobic materials for insulin syringes. Its components and preparation methods are basically the same as in Example 1, except that in this example, in the process of preparing p-hydroxybenzoic acid modified starch , the addition amount of cornstarch and p-hydroxybenzoic acid were 40kg and 16kg respectively, and the degree of esterification of p-hydroxybenzoic acid modified starch was 0.08.

Embodiment 3

[0097] Example 3: Another processing method for insulin syringes:

[0098] This example provides another method for processing and molding hydrophobic materials for insulin syringes. Its components and preparation methods are basically the same as in Example 1, except that in this example, in the process of preparing p-hydroxybenzoic acid modified starch , the addition amount of cornstarch and p-hydroxybenzoic acid were 40kg and 24kg respectively, and the degree of esterification of p-hydroxybenzoic acid modified starch was 0.12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com