Water-based plant-based quick-drying polyurethane finish paint and preparation method thereof

A polyurethane topcoat, plant-based technology, used in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor chemical resistance and scratch resistance, high VOC content in two-component coatings, and improve drying. speed, reduced VOC content, improved chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

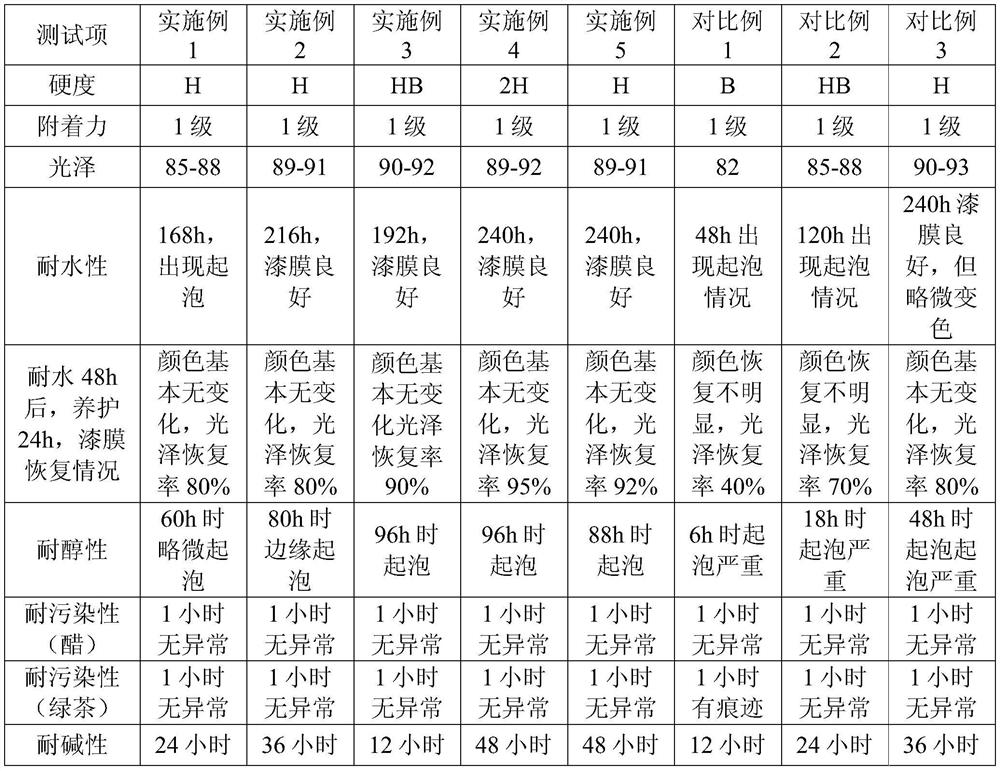

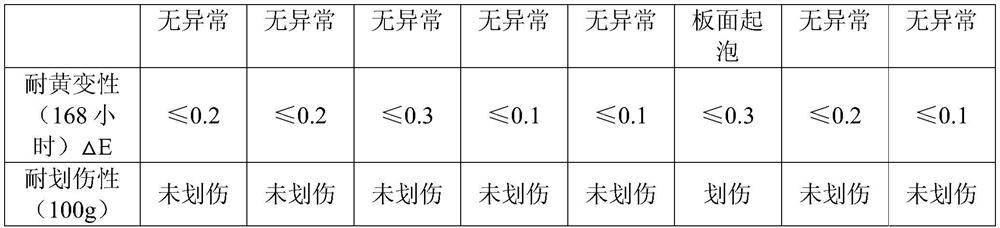

Examples

Embodiment 1

[0043] A water-based plant-based quick-drying polyurethane topcoat, comprising the following components in parts by weight:

[0044] Component A: 60 parts of water-based hydroxyl acrylic emulsion, 1 part of water-based UV absorber, 0.2 part of neutralizer, 0.2 part of defoamer, 0.8 part of dispersant, 12 parts of pigment, 0.6 part of leveling agent, substrate wetting agent 0.6 parts, 13.59 parts of deionized water, 1 part of thickener, 0.01 parts of catalyst;

[0045]Component B: 10 parts of aliphatic polyisocyanate, 2.5 parts of propylene glycol diacetate.

[0046] The preparation steps are as follows:

[0047] (1) Add 8.15 parts of deionized water, 0.1 part of neutralizer, 0.2 part of defoamer, 0.8 part of dispersant, and 12 parts of pigment into the stock preparation pot in turn, control the speed of 500-800r / min, stir for more than 20min, and stir evenly Finally, it is ground to obtain the early stage slurry, and the grinding fineness is ≤20 μm.

[0048] (2) Add 60 part...

Embodiment 2

[0053] A water-based plant-based quick-drying polyurethane topcoat, comprising the following components in parts by weight:

[0054] Component A: 65 parts of water-based hydroxyacrylic emulsion, 0.6 part of water-based UV absorber, 0.2 part of neutralizer, 0.2 part of defoamer, 0.8 part of dispersant, 12 parts of pigment, 0.5 part of leveling agent, substrate wetting agent 0.5 parts, 6.38 parts of deionized water, 0.8 parts of thickener, 0.02 parts of catalyst;

[0055] Component B: 13 parts of aliphatic polyisocyanate, 3.25 parts of propylene glycol diacetate.

[0056] The preparation steps are as follows:

[0057] (1) Add 3.83 parts of deionized water, 0.1 part of neutralizer, 0.2 part of defoamer, 0.8 part of dispersant, and 12 parts of pigment into the stock preparation pot in turn, control the speed of 500-800r / min, stir for more than 20min, and stir evenly Finally, it is ground to obtain the early stage slurry, and the grinding fineness is ≤20 μm.

[0058] (2) Add 65 ...

Embodiment 3

[0063] A water-based plant-based quick-drying polyurethane topcoat, comprising the following components in parts by weight:

[0064] Component A: 70 parts of water-based hydroxyl acrylic emulsion, 0.9 part of water-based UV absorber, 0.3 part of neutralizer, 0.2 part of defoamer, 0.8 part of dispersant, 12 parts of pigment, 0.5 part of leveling agent, substrate wetting agent 0.5 parts, 4.27 parts of deionized water, 0.5 parts of thickener, 0.03 parts of catalyst;

[0065] Component B: 10 parts of aliphatic polyisocyanate, 2.5 parts of propylene glycol diacetate.

[0066] The preparation steps are as follows:

[0067] (1) Add 2.56 parts of deionized water, 0.15 parts of neutralizer, 0.2 parts of defoamer, 0.8 parts of dispersant, and 12 parts of pigments into the stock preparation pot in turn, control the speed of 500-800r / min, stir for more than 20min, and stir evenly Finally, it is ground to obtain the early stage slurry, and the grinding fineness is ≤20 μm.

[0068] (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com