A stainless steel pipe doped with element cerium p92 and its post-welding cycle heat treatment method

A heat treatment method and a technology of doping elements, which are applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems that the performance of P91 steel cannot meet the production requirements, so as to improve the degree of solid solution strengthening, increase the tensile strength and durable strength, The effect of internal tissue homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

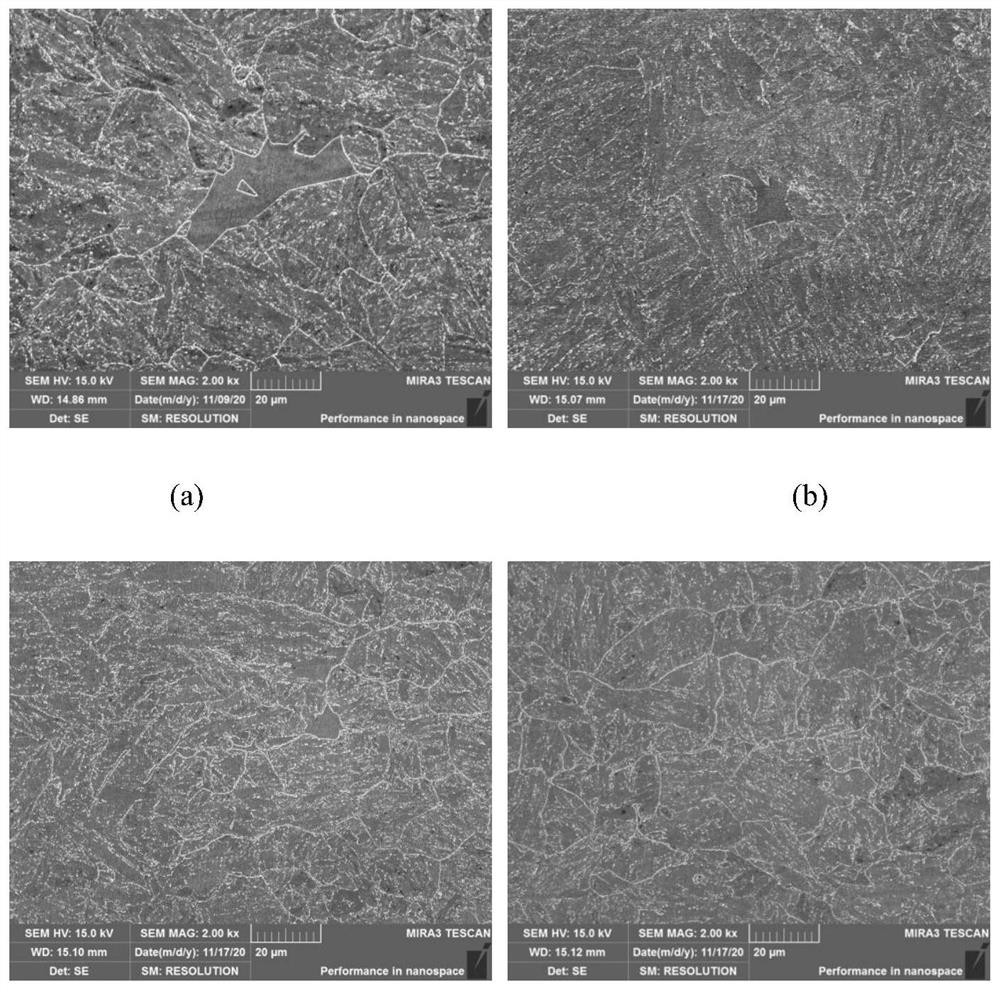

[0060] The chemical composition and mass percentage of the doped element cerium P92 steel pipe are: C (0.112), Cr (8.831), Ni (0.235), Mn (0.409), W (1.936), Mo (0.386), V (0.209), Si (0.241), balance Fe and unavoidable impurity elements.

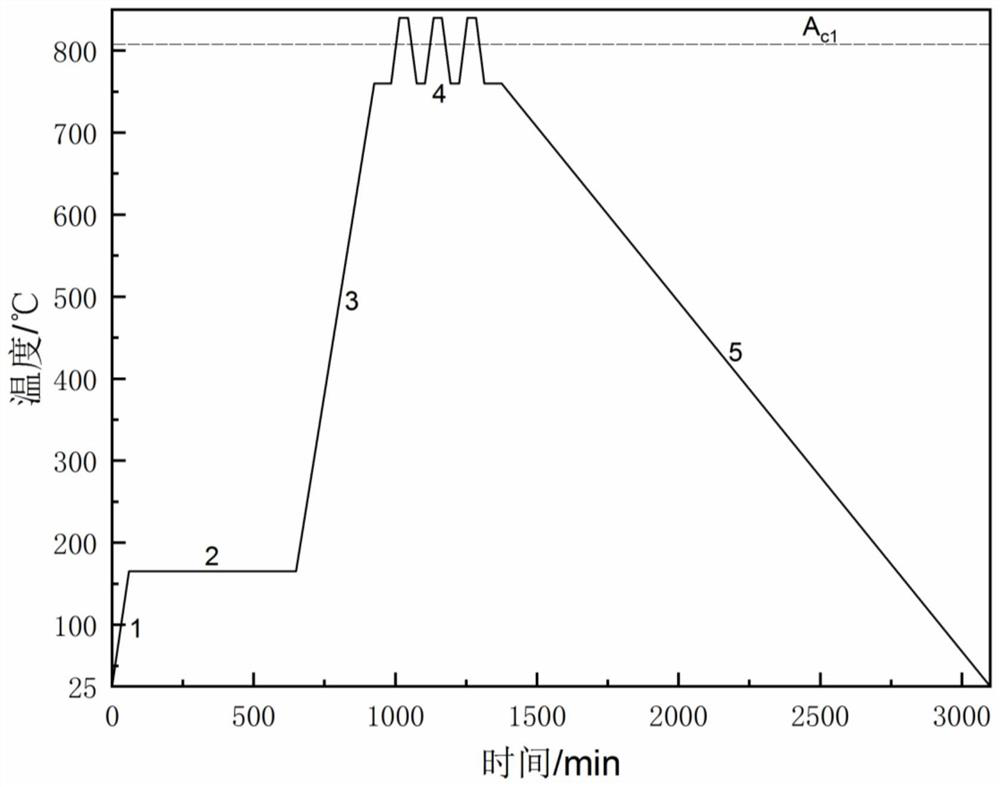

[0061] The post-weld heat treatment method for steel pipes as described above includes five steps of temperature rise 1, heat preservation 2, temperature rise 3, heat preservation 4, and temperature reduction 5 steps. step.

[0062] Step 1 of temperature rise includes raising the temperature of the steel pipe from 25°C to preheat the welded steel pipe to 165°C and keep it warm for 10 hours. The temperature rise rate during the preheating process is 140°C per hour.

[0063] The heat preservation 2 step includes heat preservation of the treated steel pipe at 165° C. for 16.5 hours.

[0064] The 3rd step of heating includes raising the treated steel pipe from 165°C; then raising the temperature of the steel pipe to 760°C and keeping it warm ...

Embodiment 2

[0068] The chemical composition and mass percentage of the doped element cerium P92 steel pipe are: C (0.112), Cr (8.831), Ni (0.235), Mn (0.409), W (1.936), Mo (0.386), V (0.209), Si(0.241), Ce(0.1), balance Fe and unavoidable impurity elements.

[0069] The post-weld heat treatment method for steel pipes as described above includes five steps of temperature rise 1, heat preservation 2, temperature rise 3, heat preservation 4, and temperature reduction 5 steps. step.

[0070] Step 1 of temperature rise includes raising the temperature of the steel pipe from 25°C to preheat the welded steel pipe to 165°C and keep it warm for 10 hours. The temperature rise rate during the preheating process is 140°C per hour.

[0071] The heat preservation 2 step includes heat preservation of the treated steel pipe at 165° C. for 16.5 hours.

[0072] The 3rd step of heating includes raising the treated steel pipe from 165°C; then raising the temperature of the steel pipe to 760°C and keeping ...

Embodiment 3

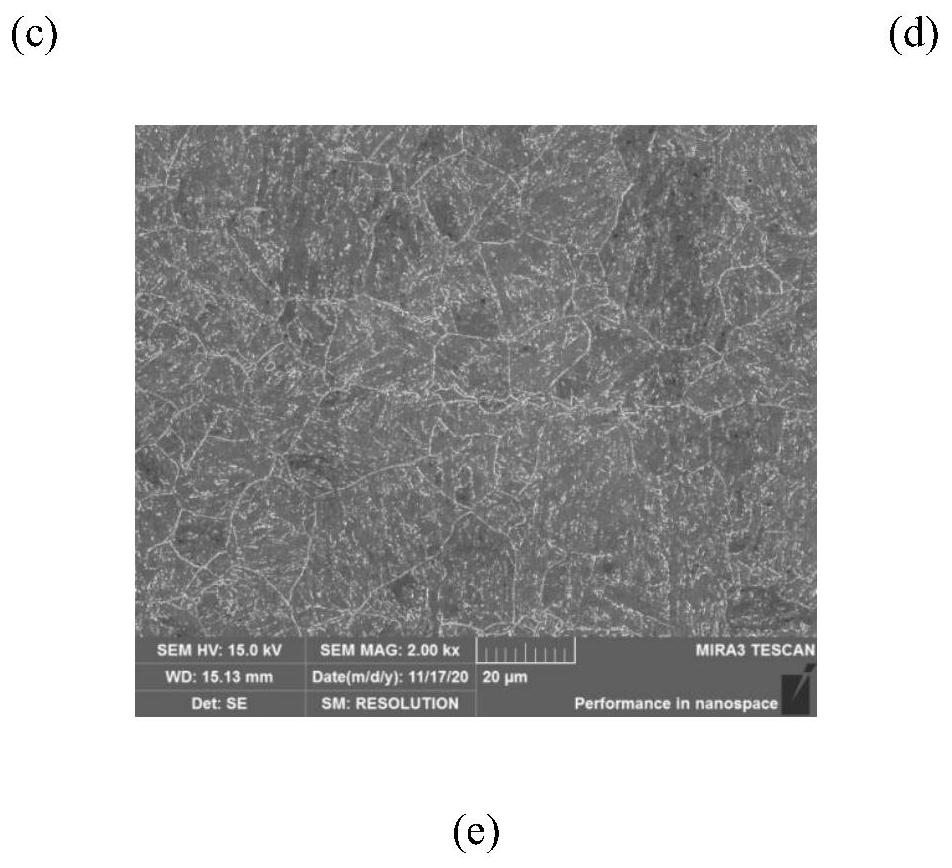

[0076] The chemical composition and mass percentage of the doped element cerium P92 steel pipe are: C (0.112), Cr (8.831), Ni (0.235), Mn (0.409), W (1.936), Mo (0.386), V (0.209), Si(0.241), Ce(0.2), balance Fe and unavoidable impurity elements.

[0077] The post-weld heat treatment method for steel pipes as described above includes five steps of temperature rise 1, heat preservation 2, temperature rise 3, heat preservation 4, and temperature reduction 5 steps. step.

[0078] Step 1 of temperature rise includes raising the temperature of the steel pipe from 25°C to preheat the welded steel pipe to 165°C and keep it warm for 10 hours. The temperature rise rate during the preheating process is 140°C per hour.

[0079] The heat preservation 2 step includes heat preservation of the treated steel pipe at 165° C. for 16.5 hours.

[0080] The 3rd step of heating includes raising the treated steel pipe from 165°C; then raising the temperature of the steel pipe to 760°C and keeping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com