Rapid cooling and ironing workbench for garment processing

A rapid cooling and workbench technology, applied to ironing boards, applications, washing devices, etc., can solve the problems of inconvenient placement, low efficiency, and wrinkling, and achieve simple and practical structure, accelerated cooling speed, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

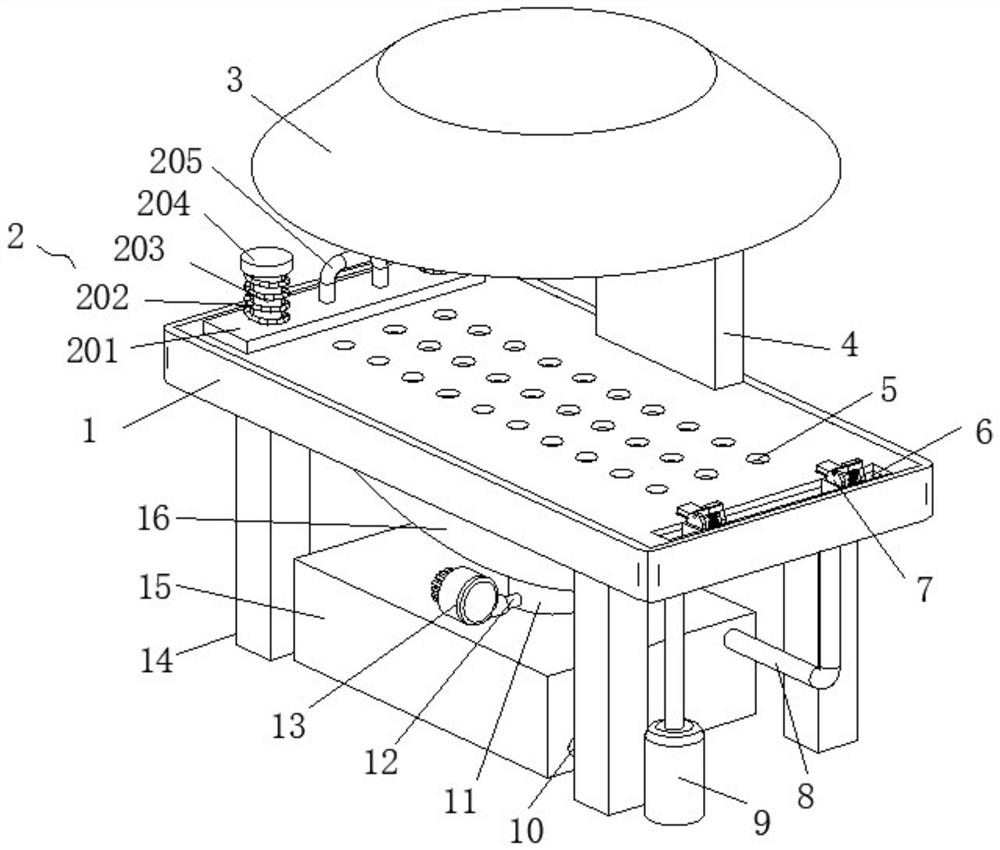

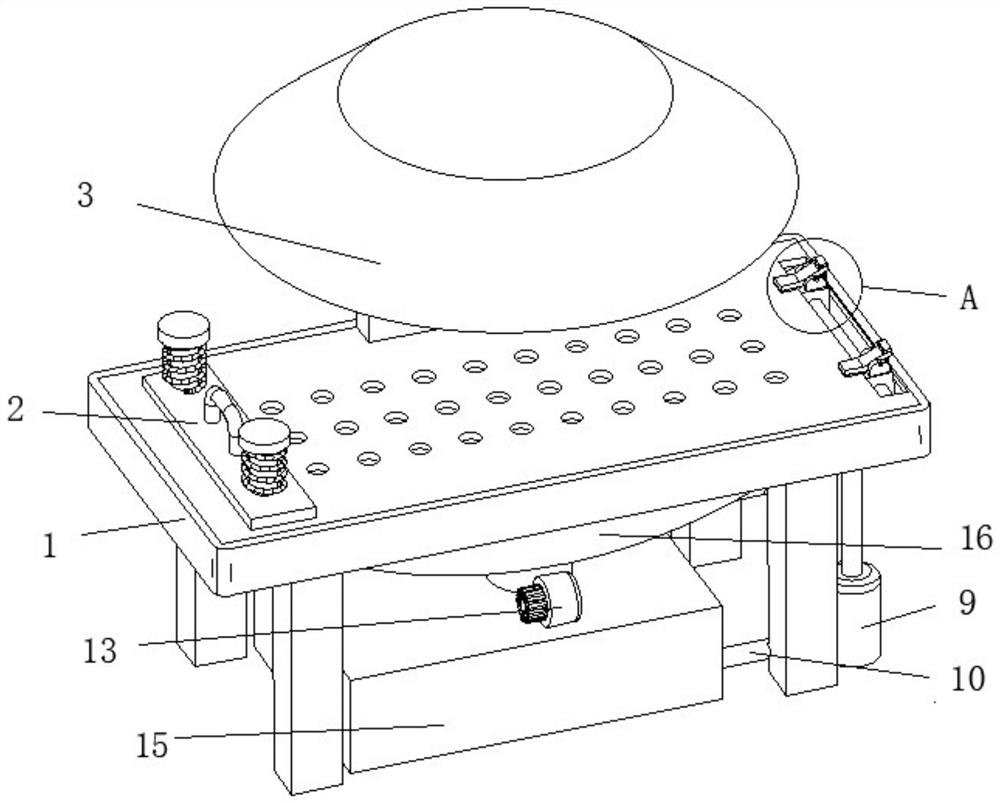

[0027] see Figure 1-7 , the present invention provides a technical solution: a rapid cooling ironing workbench for garment processing, including a workbench body 1, the upper surface of the workbench body 1 is fixedly connected with a fixed clamping mechanism 2, and the upper surface of the workbench body 1 is provided with a rectangular groove 6. The inner wall of the rectangular groove 6 is fixedly connected with a slide bar 19, and the outer wall of the slide bar 19 is slidably connected with an adjustment clamping mechanism 7. The inside of the workbench body 1 is provided with a heat dissipation cooling pipe 8, and one end of the heat dissipation cooling pipe 8 extends to the working surface. The bottom of the table body 1 is fixedly connected with a water tank 15, and the other end of the heat dissipation cooling pipe 8 extends to the bottom of the workbench body 1 and is fixedly connected with a water pump 9. The top of 15 is provided with a water inlet 22, and the ins...

Embodiment 2

[0030] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the fixed clamping mechanism 2 includes two central columns 203, the bottoms of the two central columns 203 are fixedly connected with the workbench body 1, and the two central columns 203 The tops of the two center columns 203 are fixedly connected with the limit top plate 204, and the outer wall of the center column 203 is slidably connected with a pressure plate 201. The outside of the two center columns 203 and between the pressure plate 201 and the limit top plate 204 are all provided with a fixed spring 202. The top of the pressure plate 201 The handle 205 is fixedly connected, and the adjustment clamping mechanism 7 includes a rectangular block 701. The inside of the rectangular block 701 is slidably connected with the slide bar 19. The top of the rectangular block 701 is fixedly connected with a fixed seat 702, and the inside of the fixed seat 702 is c...

Embodiment 3

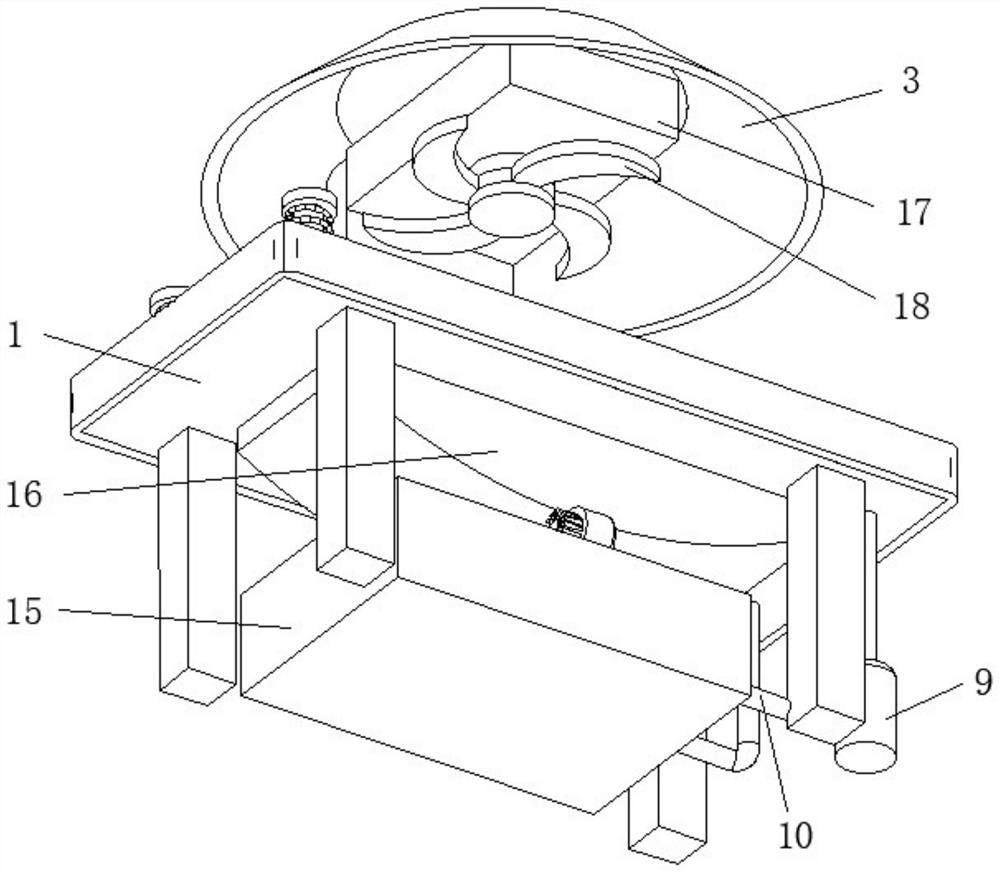

[0033] Such as Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top of the workbench body 1 is fixedly connected with a fixed plate 4, the side wall of the fixed plate 4 is fixedly connected with a mounting plate 17, and the mounting plate 17 The top of the top cover 3 is fixedly connected, and the bottom of the mounting plate 17 is fixedly equipped with a fan 18 .

[0034] In this embodiment, in addition, the fan 18 is started, and the blowing of the fan 18 is concentrated on the ironing surface of the workbench body 1 through the top cover 3, so as to speed up the air-drying and cooling speed of the ironed clothes absorbing steam, and prevent If there is moisture, folding will produce wrinkles, so that the clothes to be ironed can be put away immediately, and can be packed quickly to improve productivity.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap