Resource utilization method for mixed muck of silty-fine sand and silty clay of earth pressure shield

A silty sand and recycling technology, which is applied in the field of geotechnical engineering and tunnel engineering, can solve the problems of heavy metal and organic pollution, dregs and surrounding stratum heavy metal and organic pollution, and achieve low cost ratio and reduce slurry ratio , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with specific embodiments.

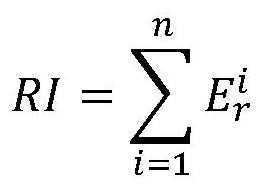

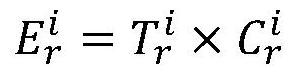

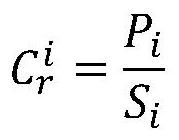

[0056] A method for resource utilization of earth pressure shield silty fine sand and silty clay mixed slag of the present invention, the method comprises the following steps:

[0057] Step S1: Collect muck

[0058] The muck is a mixture of silty fine sand and silty clay. Since fine sand is used as a slurry additive material to replace the raw river sand, adding it to the synchronous grouting slurry will reduce the fluidity of the slurry, so it is necessary to add a water reducer to improve the fluidity of the slurry, and the silty sand formation is generally mixed with silty clay, and the different content Silt and fine sand have different optimal ratios, so it is necessary to survey and sample the muck obtained by earth pressure shield tunneling to determine the content of silt and fine sand in the muck. The method to determine the content of silt and fine sand in dregs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Consistency | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com