Waste incineration fly ash washing device and waste incineration fly ash washing method

A technology of waste incineration fly ash and water washing device, applied in chemical instruments and methods, water/sludge/sewage treatment, cement production, etc., can solve problems such as high energy consumption, and achieve the effect of reducing soluble chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

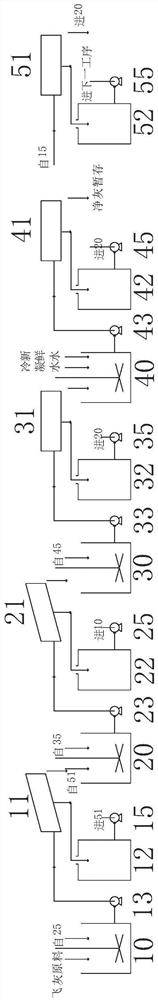

[0054] Example 1: Waste incineration fly ash washing device and four-stage washing of fly ash

[0055] see figure 1 As shown, the fly ash washing process flow of the present invention includes a mixing tank 10, a screw-stacked sludge dewatering machine 11, a water storage tank 12, a mud pump 13, a sewage pump 15, a mixing drum 20, and a screw-stacked sludge dewatering machine 21. , storage bucket 22, mud pump 23, sewage pump 25, mixing bucket 30, horizontal screw centrifuge 31, water storage bucket 32, mud pump 33, sewage pump 35, mixing bucket 40, horizontal screw centrifuge 41, water storage bucket 42 , Slurry pump 43, sewage pump 55, horizontal screw centrifuge 51, storage bucket 52.

[0056] First-stage water washing: the quantitative fly ash and the second-stage centrifugal effluent are mixed in the first-stage mixing tank 10 for a set time and then transported to the first-stage centrifuge 11 by the mud pump 13;

[0057] Second-stage water washing: the fly ash after ce...

Embodiment 2

[0061] Embodiment 2: the first-stage water washing method of fly ash

[0062] The first-stage water-washing mixing bucket is divided into 2 compartments of equal size. There are 2 mixers, 2 compartments are separated independently, 1 compartment is used for mixing, the other is used for discharging, and the 2 compartments are spare for each other. First, wash the fly ash in the second-level storage bucket for 10m 3 All are pumped into 1 grid of the first-stage water washing mixing tank, add 5 tons of fly ash, and stir while adding fly ash, and the stirring speed is 500 rpm. Stir for 30 minutes after the addition of fly ash. After stirring for 30 minutes, the mortar can be pumped into the screw-type sludge dewatering machine for centrifugation. When the second-level storage bucket fly ash washing water reaches 10m 3 , pump it into another 1 grid of the first-stage water-washing mixing tank, add 5 tons of fly ash, and the dosing method, mixing speed, and mixing time are the s...

Embodiment 3

[0063] Embodiment 3: the second-stage water washing method of fly ash

[0064] The second-stage water washing mixing barrel is divided into 2 compartments, and the form is the same as that of the first-stage water washing. The second-level water washing first requires washing the fly ash in the third-level storage bucket for 10m 3 All are pumped into the second-stage water-washing mixing tank for 1 grid, and the washed ash removed from the first-stage centrifuge and the ash after the concentrated brine centrifugation are added, and the materials are stirred while feeding, and the stirring speed is 500 rpm. Stir for 30 minutes after the feeding is completed. After stirring for 30 minutes the mortar can be dewatered by centrifugation. There is no need to measure the weight of washed ash and ash residue in the second-stage water washing feeding, and the feeding time is determined by the discharge speed of the centrifuge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com