Fired brick and preparation method thereof

A technology of sintered bricks and adobe, which is applied in the field of sintered bricks and its preparation, which can solve the problems of ecological environment risks and occupation of large land resources, and achieve the effects of good environment, cost saving and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

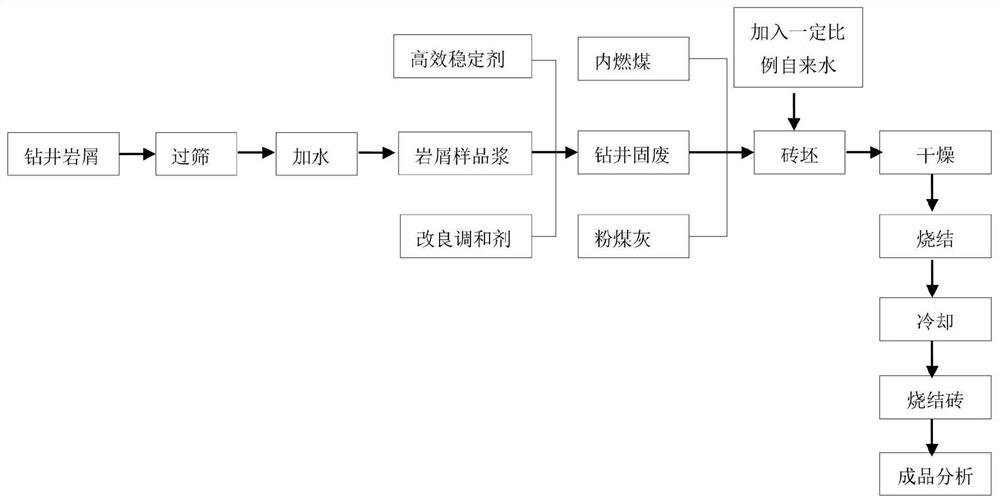

[0027] The invention provides a method for preparing sintered bricks, comprising the following steps;

[0028] Sieve the water-based drilling cuttings to obtain cuttings samples with a particle size not greater than 5mm;

[0029] Using water to adjust the moisture content of the cuttings sample to 20%±2%, to obtain the cuttings sample slurry;

[0030] Mixing the cuttings sample slurry, high-efficiency stabilizer and improved blending agent to obtain drilling solid waste;

[0031] mixing the drilling solid waste, internal combustion coal and fly ash to obtain a mixture;

[0032] Stirring and shaping the mixture with water in turn to make adobe;

[0033] The adobe is dried, sintered and cooled in sequence to obtain the sintered brick.

[0034] In the present invention, the water content of the solid drilling waste is preferably less than 40%. In the present invention, the drilling solid waste is preferably leached according to the GB5086.1-1997 method, and the COD concentrat...

Embodiment 1

[0053] figure 1 The flow chart of preparing sintered bricks for the embodiment of the present invention.

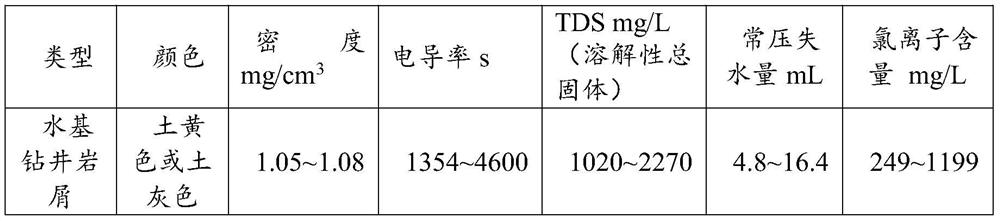

[0054] Taking water-based drilling cuttings in the Sulige Gas Field in Ordos as an example, the following processing methods are adopted:

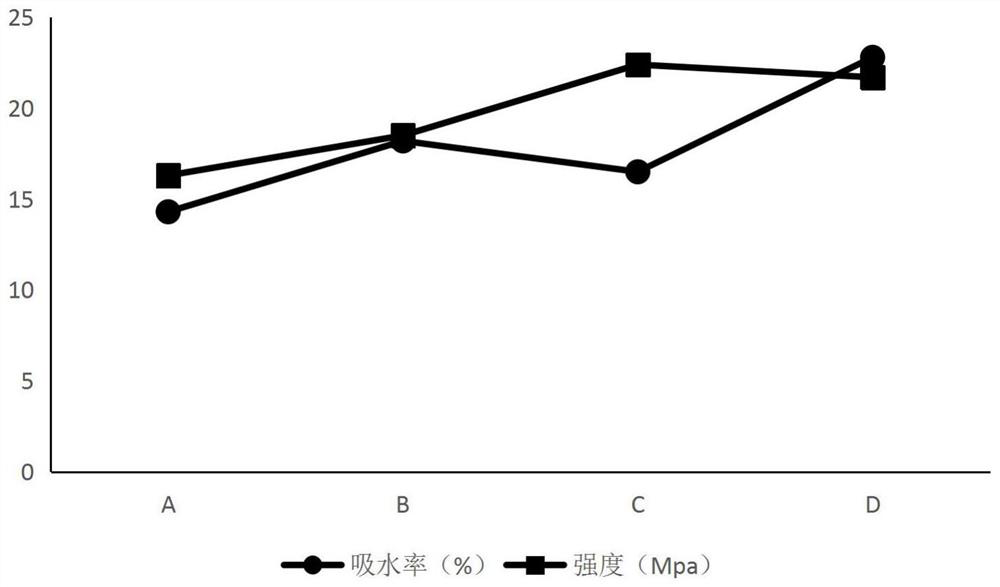

[0055] Sieve the water-based drilling cuttings (indicators shown in Table 2) to obtain cuttings samples with a particle size not greater than 5 mm. Use water to adjust the moisture content of the cuttings samples to 20%, and add a high-efficiency stabilizer (PAC, The amount used is 1.2% of the mass of the cuttings sample) and the improved blending agent (FeSO 4 , the dosage is 0.4% of the mass of the cuttings sample) and mixed evenly, then mixed with internal combustion coal and fly ash, according to the ratio of drilling solid waste: internal combustion coal: fly ash: 50-60:10:40-50 The mixture obtained by mixing is transferred to the brick-making mixing system, and a certain amount of tap water is added, stirred, shaped, and made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com