Method for designing open-type architecture flow production line supporting plug and play of equipment

A plug-and-play technology that supports equipment and is applied in design optimization/simulation, calculation, data processing applications, etc. It can solve problems such as increased difficulty in process stability, low specificity, and impact on production efficiency, and achieves scalability and ease of use. , to solve the effect of high cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

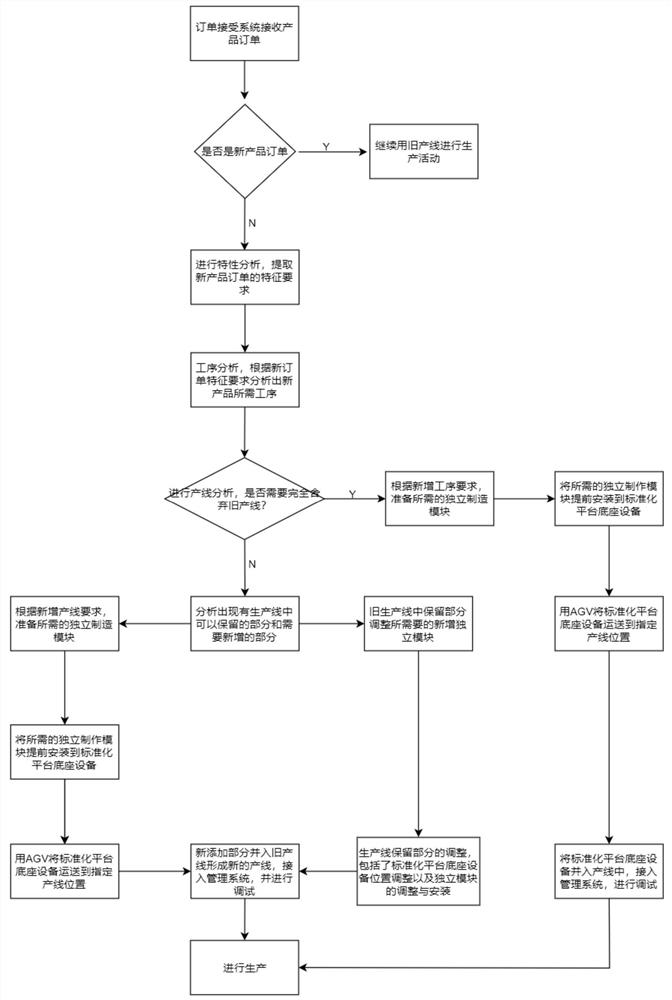

[0024] Such as figure 1 As shown, this embodiment discloses a method for designing an open architecture assembly line that supports plug-and-play equipment, and the method mainly includes the following steps:

[0025] Step S1: Receive the order request, if it is an old product, continue to use the old production line for production. In the case of a new product order, the feature requirements are extracted from the new product order for input into the system.

[0026] Step S2: Analyze the process required to produce the new product, and compare the difference between the new and old production lines according to the feature format extracted above. Judge whether it is necessary to build a new production line, and take the next step according to the judgment result.

[0027] Step S3: Prepare relevant equipment according to the requirements of the newly added process.

[0028] Step S4: Install the equipment prepared in the previous step in advance, install the independent manu...

Embodiment 2

[0039] This embodiment provides an open architecture assembly line design that supports plug-and-play equipment, and its design principles are as follows:

[0040] The open-architecture assembly line that supports plug-and-play equipment consists of an open-architecture machine tool. The improvement of reconfigurable capability brought by open architecture means that such reconfigurable manufacturing equipment (including reconfigurable elements, parameters and components) needs to be modeled. When the production plan changes and the production line needs to be adjusted, the machine tool equipment can be converted to quickly form a production line that can adapt to the new production plan. In short, an open-architecture production line that supports plug-and-play equipment is composed of independent, upgradable and exchangeable open-architecture machine tools. The open structure machine tool equipment is composed of independent, upgradeable and exchangeable modules.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com