Gas-liquid reaction device as well as use method and application thereof

A gas-liquid reaction and reaction tube technology, applied in chemical methods, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors for reacting liquids and gaseous media, etc., can solve the problems of phase interface transfer and slow reaction , small heat exchange area, high local temperature problems, to achieve the effect of fast and efficient mixing reaction, large contact area and less material inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

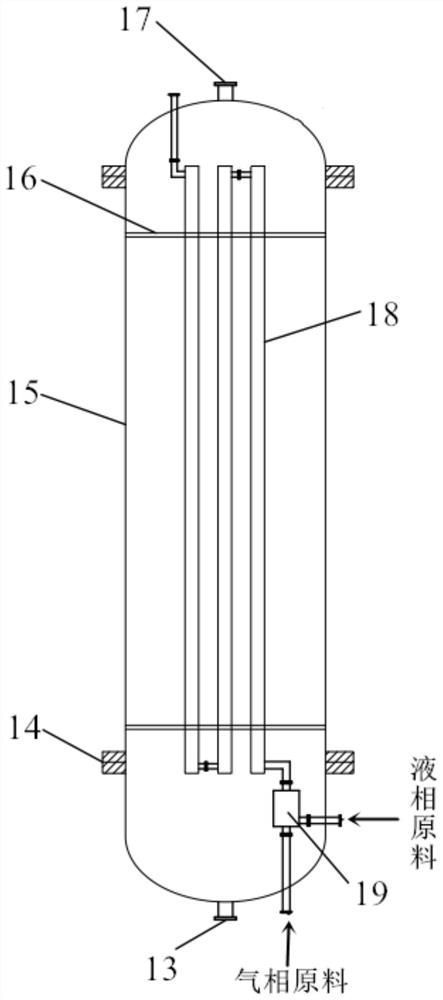

[0091] This embodiment provides a gas-liquid reaction device based on a gas-liquid reaction device provided in a specific embodiment, wherein:

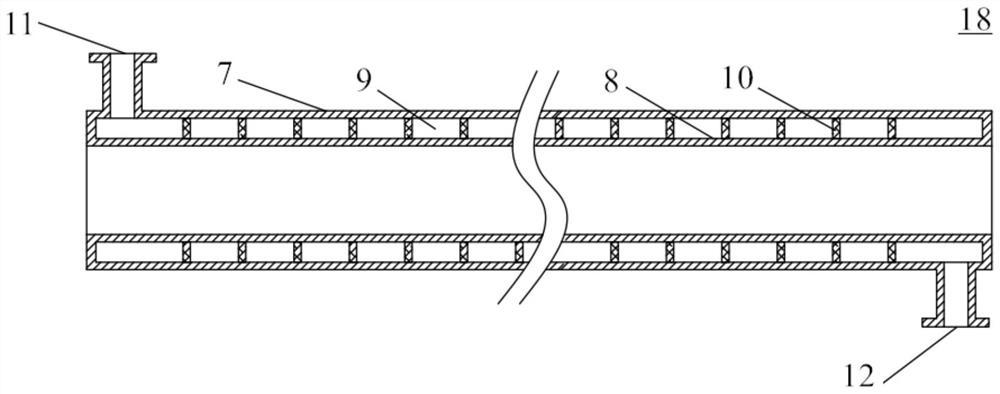

[0092] The reaction pipes 18 are connected in series, along the flow direction of the reaction liquid, the discharge pipe 3 of the gas dispersion module 19 is connected to the feed port 11 of the first reaction pipe 18, and the discharge port 12 of the first reaction pipe 18 is connected to the next The feed port 11 of the reaction pipe 18, according to this connection mode, each reaction pipe 18 is connected in series along the flow direction of the reaction liquid, and the reaction liquid discharged through the gas dispersion module 19 is passed into the first reaction pipe 18 through the discharge pipe 3, and then sequentially Flow through the annular channel 9 of each reaction tube 18 .

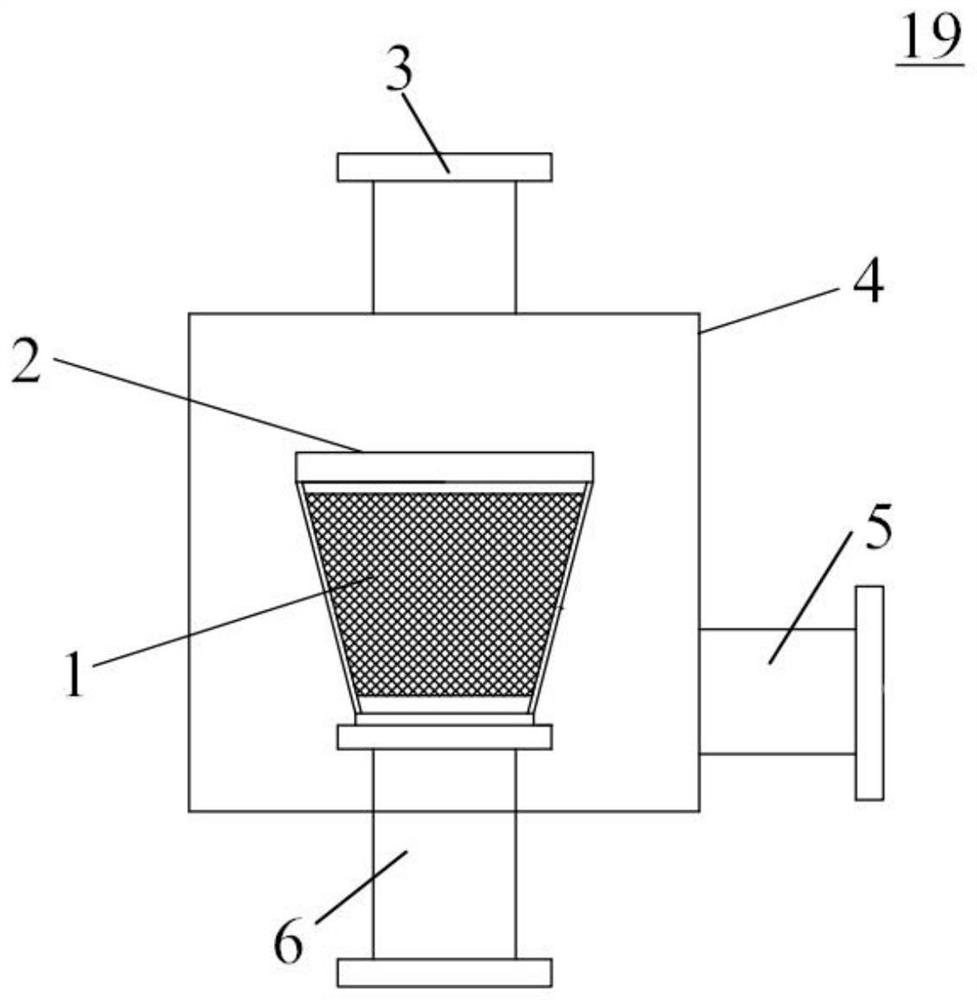

[0093] The microporous membrane module 1 is surrounded by a microporous membrane, the membrane material of the microporous membrane is high mole...

Embodiment 2

[0096] Adopt the gas-liquid reaction device that embodiment 1 provides to synthesize tetrahydrophthalic anhydride, and synthetic method specifically comprises the following steps:

[0097] (1) Benzene and maleic anhydride are mixed according to the mass ratio of 0.1:1 to obtain maleic anhydride solution, butadiene gas and maleic anhydride solution are respectively passed in the gas dispersion module 19, butadiene gas and maleic anhydride The mol ratio of the maleic anhydride in the butenedioic anhydride solution is 1:1;

[0098] After the butadiene gas enters the gas dispersion module 19, it passes through the microporous membrane assembly 1 at a linear speed of 0.1m / s to form microbubbles and diffuses into the maleic anhydride solution to obtain a reaction solution;

[0099] (2) The reaction liquid flows into the annular channel 9 of the reaction pipe fitting 18 at a linear velocity of 0.05m / s, and at the same time, the heat exchange medium is passed into the inner pipe body ...

Embodiment 3

[0102] This embodiment provides a gas-liquid reaction device based on a gas-liquid reaction device provided in a specific embodiment, wherein:

[0103] When the reaction pipe fittings 18 are connected in parallel, the inlet and outlet ends of the reaction pipe fittings 18 are connected to the feed main pipe and the discharge pipe respectively, and the discharge pipe 3 of the gas dispersion module 19 is connected to the feed main pipe. The ports 11 are respectively connected to the feed main pipes, and the reaction liquid discharged through the gas dispersion module 19 is passed through the discharge pipe 3 into the feed main pipes, and distributed into the annular channels 9 of the reaction pipes 18 .

[0104]The microporous membrane module 1 is surrounded by a microporous membrane, the membrane material of the microporous membrane is ceramics, and the pore diameter of the microporous membrane is 10 μm. The microporous membrane module 1 is an inverted truncated cone structure,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com