Catalyst for producing high-carbon olefins from a mixture of carbon dioxide and hydrogen, and its preparation and application method

A carbon dioxide and high-carbon olefin technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low C4+ olefin selectivity and difficulty in realizing industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

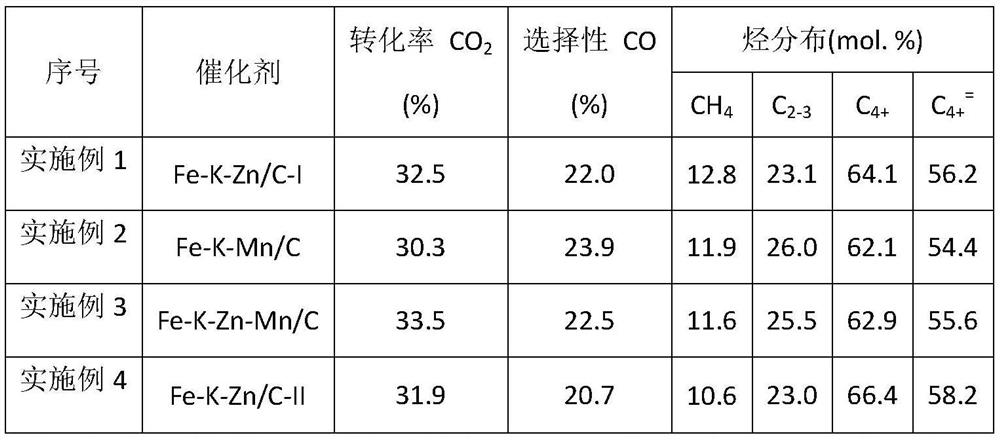

Examples

Embodiment 1

[0028] The composite catalyst preparation process is as follows:

[0029] Prepare 50mL of 0.6mol / L hydrochloric acid solution, after cooling in ice water at 0-4°C, weigh 6 grams of FeC2O4·2H2O solid, add it to hydrochloric acid for ultrasonic dissolution, then weigh 1.6 grams of KCl solid and 0.6 grams of ZnCl2 solid into the above The solution was ultrasonically dissolved, and the dissolved solution was heated in a water bath at 60°C to evaporate excess acid and water, then transferred to an oven, and dried at 100°C for 10 hours. That is, the prepared catalyst is Fe-K-Zn. Take 9 grams of carbon nanotubes, mix them with the above-mentioned obtained Fe-K-Zn catalyst powder grinding machinery, and press tablet molding, and the prepared catalyst is designated as Fe-K-Zn / C-I.

[0030] The prepared catalyst is applied to the catalytic reaction of CO2 hydrogenation conversion to olefins. The catalyst was first activated in situ at 400 °C for 8 h under hydrogen. After reduction, t...

Embodiment 2

[0032] The composite catalyst preparation process is as follows:

[0033] Prepare 100mL of 0.6mol / L hydrochloric acid solution, after ice-water cooling, weigh 6 grams of FeC2O4·2H2O powder, add it into hydrochloric acid for ultrasonic dissolution, then weigh 1.6 grams of KCl powder and 0.9mL of 50% Mn(NO3)2 solution and add The above solution was ultrasonically dissolved, and the dissolved solution was heated in a water bath at 60°C to evaporate excess acid and water, then transferred to an oven, and dried at 100°C for 10 hours. That is, the obtained catalyst is Fe-K-Mn. Take by weighing 9 grams of activated carbon, mix with the above-mentioned obtained Fe-K-Mn catalyst powder grinding machine, tablet molding, and the prepared catalyst is designated as Fe-K-Mn / C.

[0034] The prepared catalyst is applied to the catalytic reaction of CO2 hydrogenation conversion to olefins. The catalyst was first activated in situ at 400 °C for 8 h under hydrogen. After reduction, the temper...

Embodiment 3

[0036] The composite catalyst preparation process is as follows:

[0037] Configure 100mL of 0.6mol / L hydrochloric acid solution, after ice-water cooling, weigh 6 grams of FeC2O4 2H2O powder, add it to hydrochloric acid for ultrasonic dissolution, then weigh 1.6 grams of KCl solid and 0.3 grams of ZnCl2 solid, 50% Mn(NO3) 2 Solution 0.45mL was added to the above solution for ultrasonic dissolution. The dissolved solution was heated in a water bath at 60°C to evaporate excess acid and water, then transferred to an oven, and dried at 100°C for 10 hours. That is, the obtained catalyst is Fe-K-Zn-Mn. Take by weighing 9 grams of activated carbon, mix with the above-mentioned obtained Fe-K-Zn-Mn catalyst powder grinding machine, and press tablet molding, and the prepared catalyst is designated as Fe-K-Zn-Mn / C.

[0038] The prepared catalyst is applied to the catalytic reaction of CO2 hydrogenation conversion to olefins. The catalyst was first activated in situ at 400 °C for 8 h un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com