Coating surface modification device based on thermal spraying process and working method

A surface modification and thermal spraying technology, which is applied to the surface coating liquid device, spray device, coating, etc., can solve the problem of affecting the application range and service life of the coating, incomplete filling of surface pores and cracks, and high residual Stress and other issues to achieve the effect of ensuring purity and performance, improving quickly, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

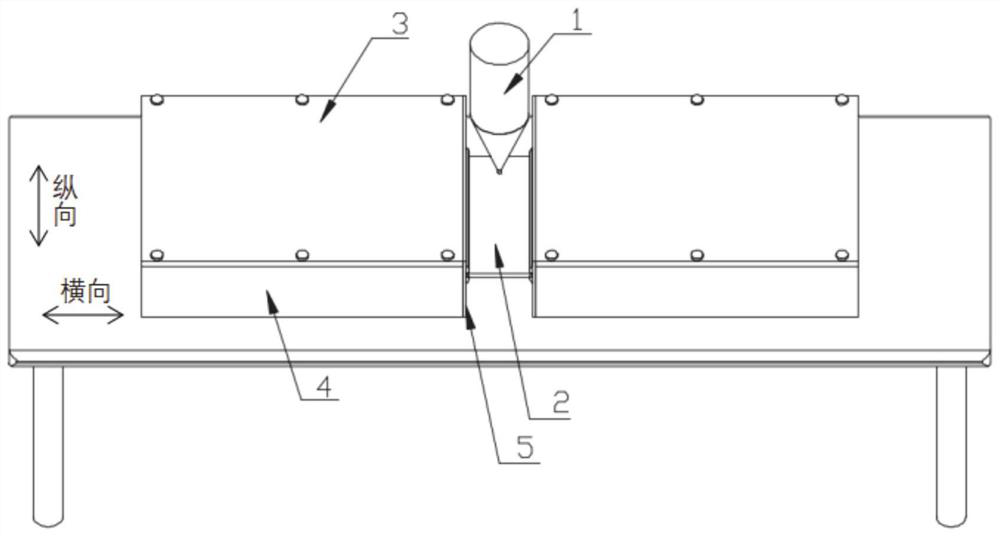

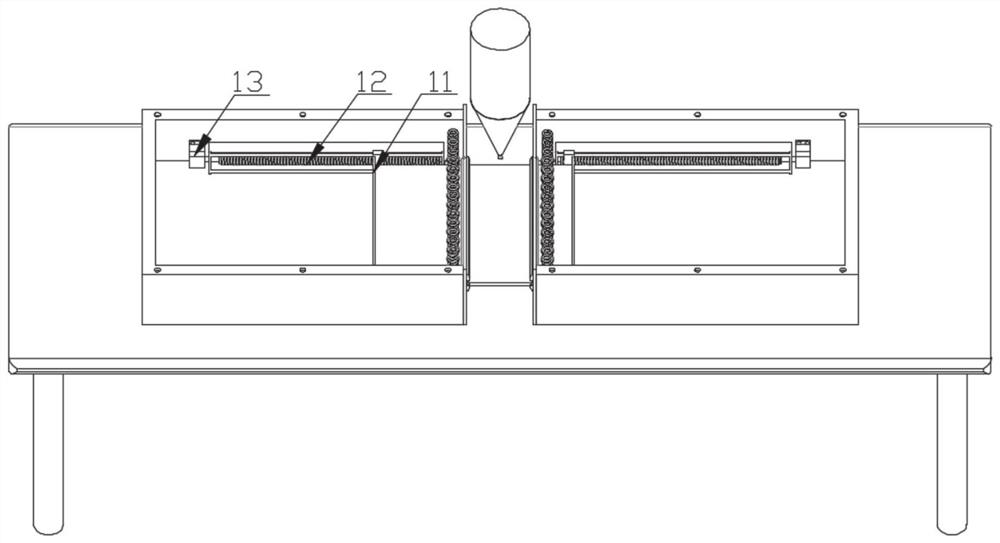

[0051] In a typical embodiment of the present invention, refer to figure 1 Shown, a kind of coating surface modification device based on thermal spraying process, comprises housing 4, has chamber in housing 4, and chamber has width, length and height of setting, and housing is the workpiece in plasma spraying process Provide the basis for adjusting the environment with a certain inert gas atmosphere, temperature and pressure.

[0052] A moving mechanism is provided on the inside or outside of the casing 4, and the side plate 5 on the side of the casing is provided with an opening. The moving mechanism can drive the workpiece 2 to move through the opening, and the protective gas can be introduced into the casing, and the casing is provided with an elastic in and out mechanism on the opening side. , to ensure that the workpiece 2 enters the inner chamber of the housing and ensures the sealing of the housing; the spray gun 1, the spray gun 1 is arranged outside the housing 4; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com