High-strength and high-plasticity layered heterogeneous magnesium-lithium composite material and preparation method thereof

A composite material and high plasticity technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of limited lifting effect, achieve simple preparation method, excellent plastic deformation ability, and easy control of material shape and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

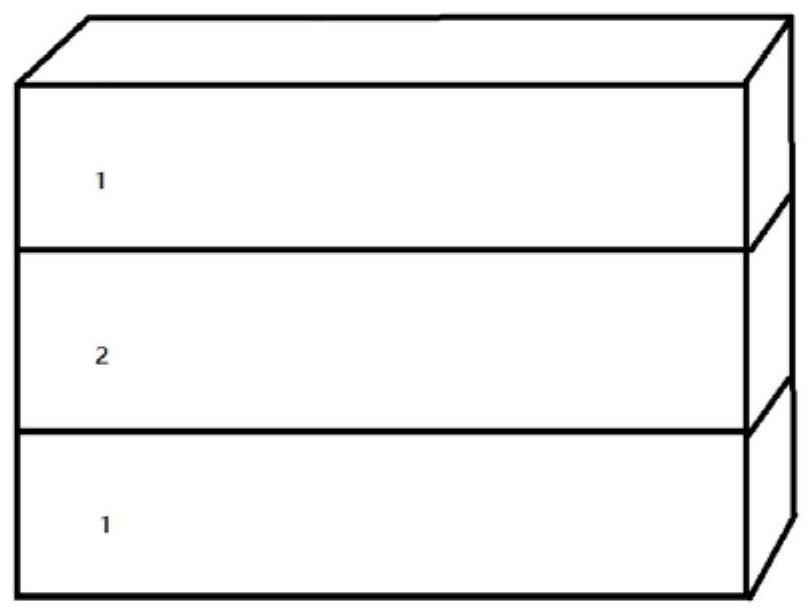

[0030] A layered magnesium-lithium heterogeneous material plate, the material used includes two kinds of magnesium-lithium alloys, and the present invention takes LA103Z magnesium-lithium alloy and LA43M magnesium-lithium alloy as examples. It is characterized in that two magnesium-lithium alloys with different strong plastic properties are stacked and rolled in a "sandwich" manner to achieve a heterogeneous structure.

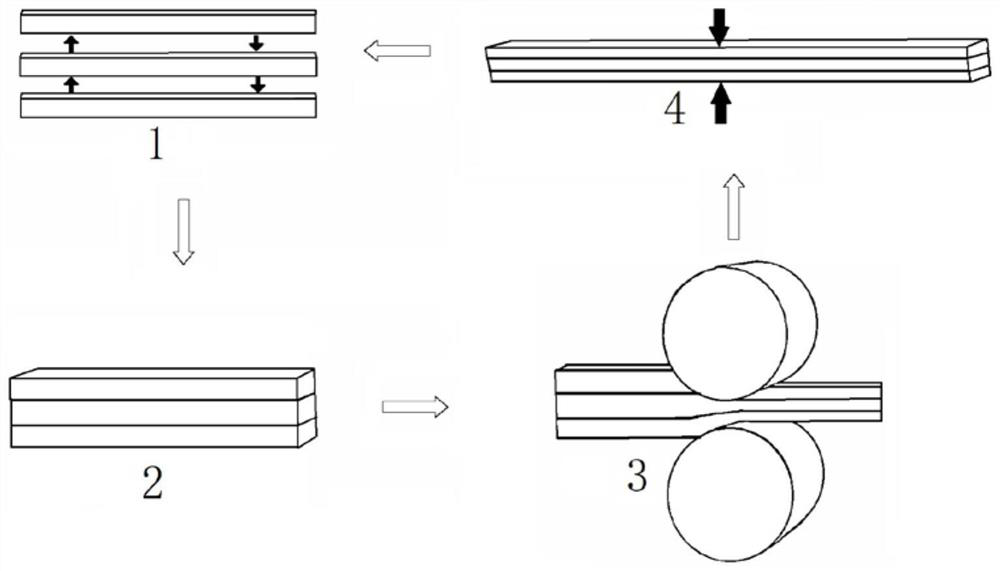

[0031] The preparation method of the above-mentioned layered magnesium-lithium heterogeneous material plate is characterized in that it comprises the following steps:

[0032] Step 1: First take LA103Z and LA43M magnesium-lithium alloy plates with a size of 50mmⅹ30mmⅹ3.5mm, then sand the joint surface-clean with acetone ultrasonically for 20min, and finally blow dry.

[0033] Step 2: Stack the obtained magnesium-lithium composite materials together according to the "sandwich" structure of LA43M / LA103Z / LA43M, drill four holes on the alloy plate with a 2mm drill...

Embodiment 2

[0036] Step 1: Take two magnesium-lithium plates LA91 and LA43M each with a size of 50mmⅹ25mmⅹ3.5mm, polish to remove the oxide layer, and then ultrasonically treat in acetone for 20min to clean the surface. Stack the two boards after surface treatment, drill holes with a drill bit and fix them with wire.

[0037] Step 2: Put the sample in step 1 into a muffle furnace and keep it warm at 400°C for 20 minutes.

[0038] Step 3: In step 2, the sample after the heat preservation is completed is taken out, put into a roll for rolling, and the rolling reduction is 75%.

Embodiment 3

[0040] Step 1: Take two kinds of magnesium-lithium plates LA43M and LA130Z with a size of 50mmⅹ30mmⅹ3.5mm, polish their surfaces to remove the oxide layer, and then ultrasonically treat them in acetone for 20min. Stack and fix the two surface-treated plates together in the order of LA103Z / LA43M / LA103Z.

[0041] Step 2: Put the sample in step 1 into a high-temperature furnace and keep it at 400°C for 20 minutes.

[0042] Step 3: In step 2, take out the sample at the end of heat preservation, and roll it, and the rolling reduction is 55%

[0043] Step 4: Anneal the rolled sample at 300° C. for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com