High-strength and anti-cracking mass concrete

A large-volume concrete and concrete technology, which is applied in the field of concrete engineering, can solve problems such as cumbersome operation processes, and achieve the effects of prolonging the setting time, reducing heat generation, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

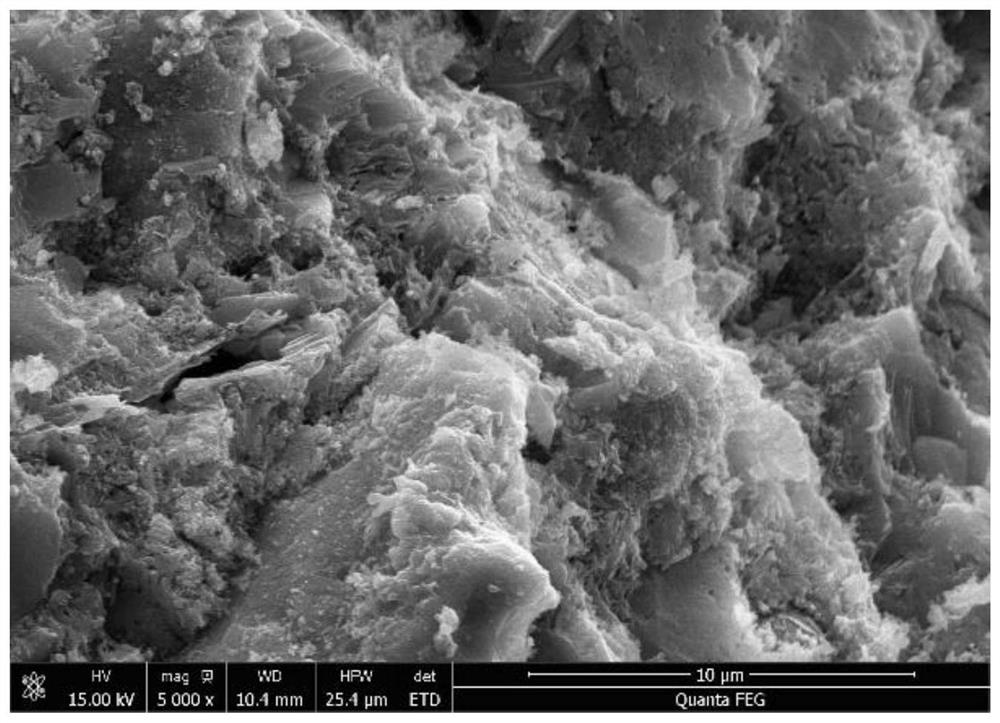

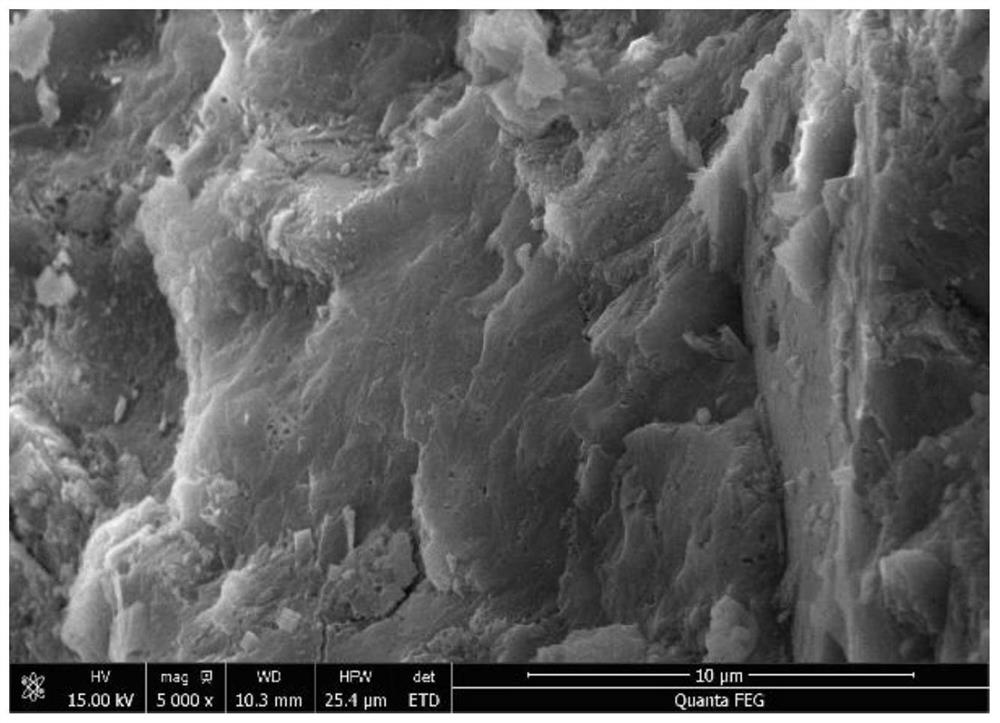

Image

Examples

Embodiment

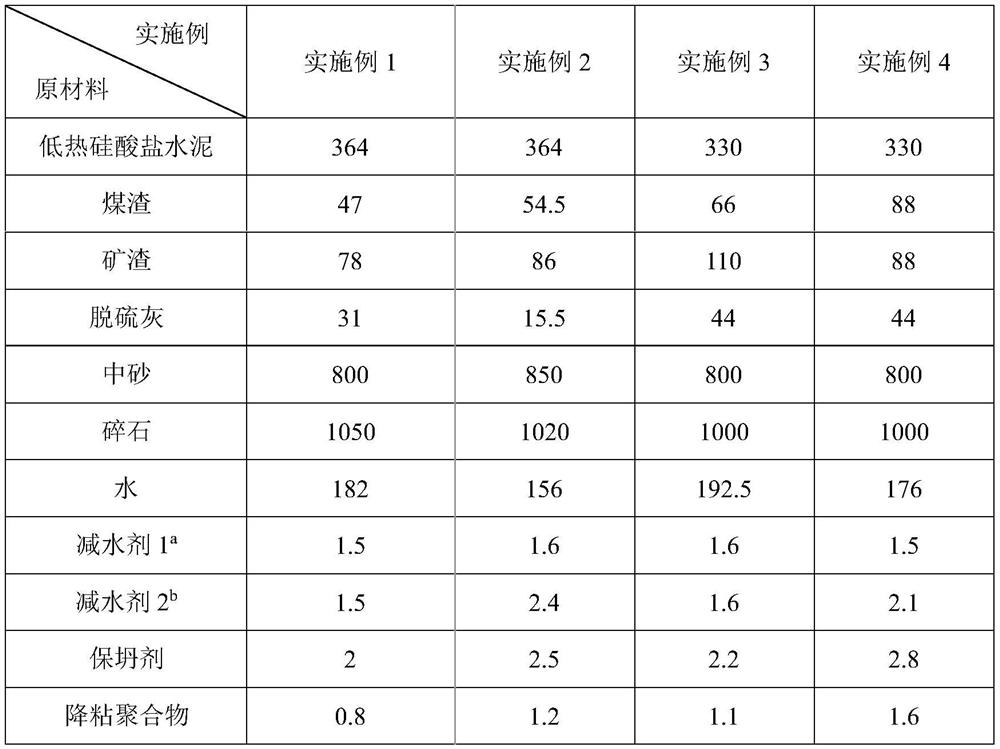

[0039] A high-strength, crack-resistant mass concrete, calculated as 1 cubic meter of concrete, the components are as follows:

[0040] Low heat portland cement 280-420kg;

[0041] Modified mineral admixture 90-260kg;

[0042] Medium sand 700-900kg;

[0043] 5-25mm continuous graded gravel 900-1200kg;

[0044] Water 150-220kg;

[0045] Functional composite admixture 5-10kg.

[0046] Further, in parts by mass, the modified mineral admixture contains 30-70 parts of slag, 25-55 parts of coal cinder, 0-35 parts of desulfurization ash, and the total mass of the three is 100 parts, and then 0.2- 0.5% sodium gluconate and 0.1-0.2% polyalcohol amine are prepared through mechanical grinding until the sieve residue of 80 μm does not exceed 10%.

[0047] Further, in terms of parts by mass, the functional composite admixture consists of 18-42 parts of low hydration heat retarding water reducer, 18-42 parts of water-retaining internal maintenance anti-cracking type water reducer, 10-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com