Biomass gasification low-emission hot blast stove

A low-emission, hot blast stove technology, applied in gasification process, fixed-bed gasification, production of combustible gas, etc. It can achieve the effect of improving energy-saving performance and safety performance, adapting to production and operation requirements, and reducing flue gas emission indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

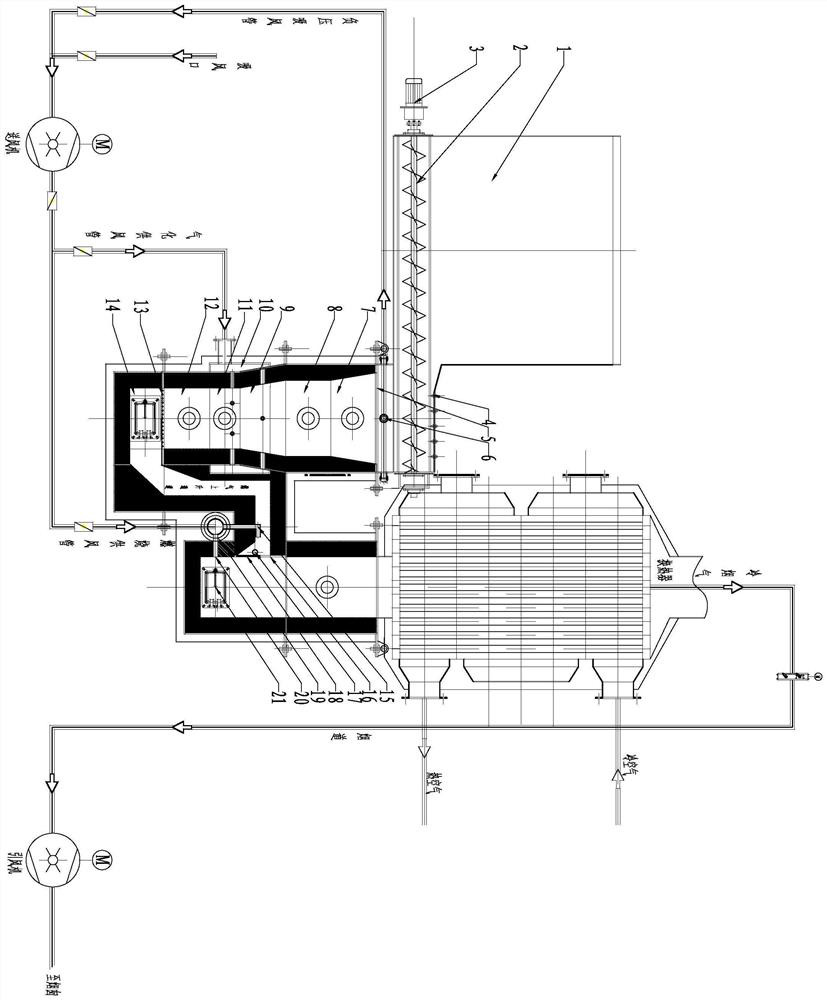

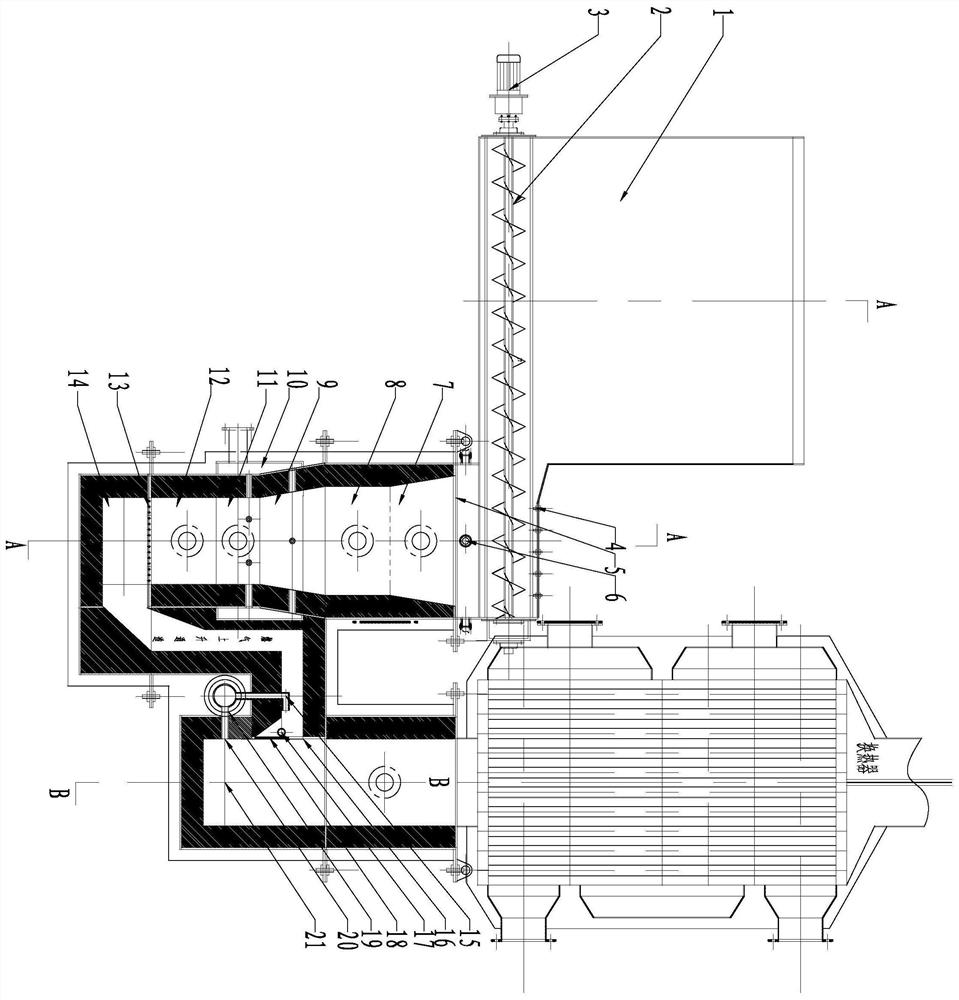

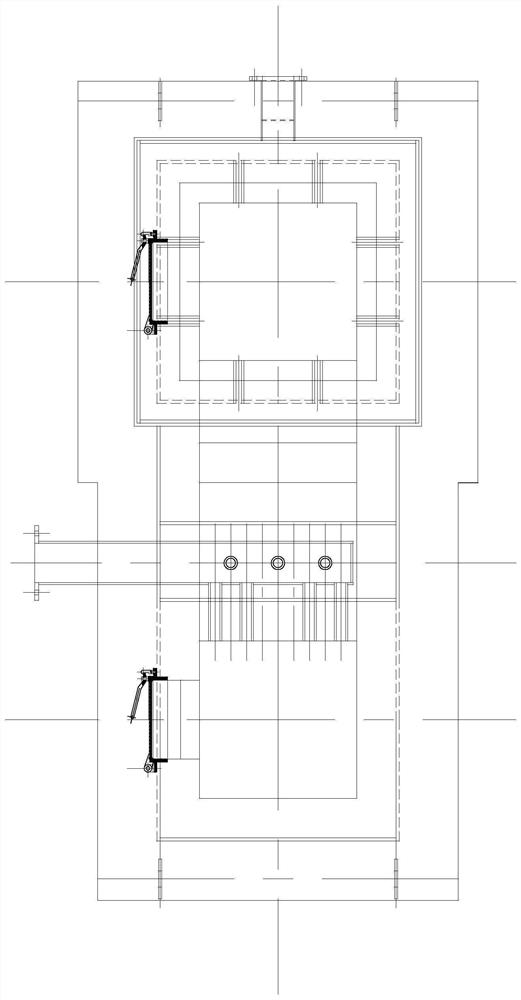

[0050] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0051] Please refer to the attached Figure 1-5 , the environmentally friendly biomass gasification combustion hot blast stove of the present invention is a downdraft gasification furnace mainly composed of four parts, a hopper and a feeding device area, a gasification area, a combustion area, a heat exchanger, a gasification area and a combustion area The whole is divided into three parts: upper, middle and lower parts to facilitate manufacturing, transportation, installation and maintenance; the three parts are connected by bolts to form a sealed whole, and the upper part is connected to the hopper and feeding device by bolts and flanges. And the four parts of the heat exchanger are sealed and connected, the flue air channel formed is a U-shaped structure, and the entire gasification device is arranged horizontally.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com