Heat-resistant austenitic stainless steel and manufacturing method thereof

A kind of austenitic stainless steel, heat-resistant technology, applied in heat-resistant austenitic stainless steel, heat-resistant austenitic stainless steel hot-rolled plate and its manufacturing field, can solve the problem of difficult to achieve high temperature strength, oxidation resistance and corrosion resistance, Problems such as low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

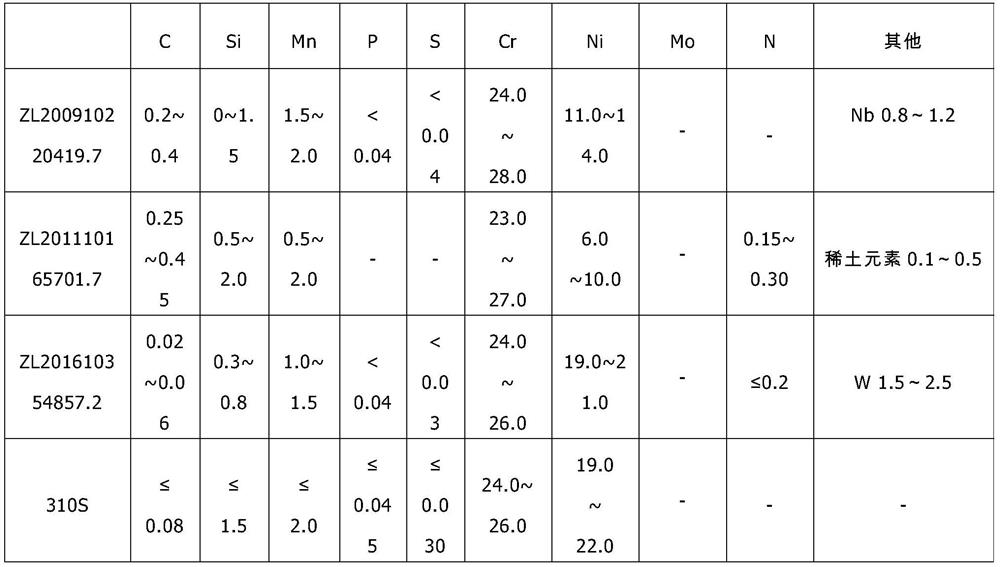

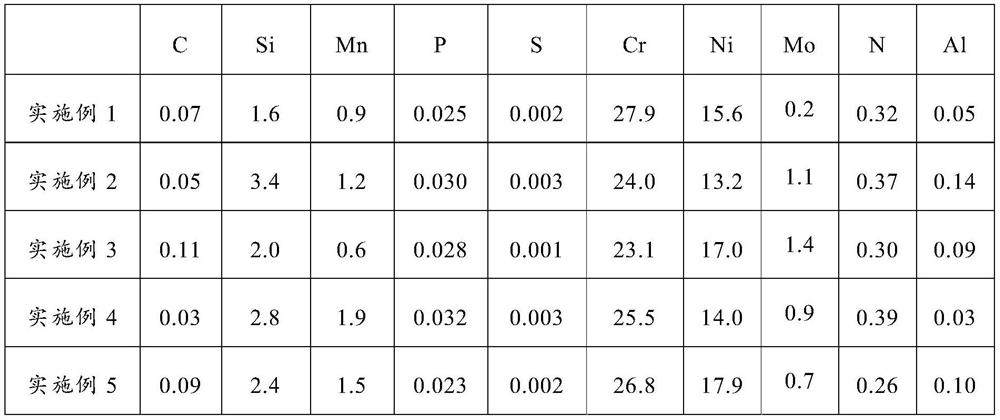

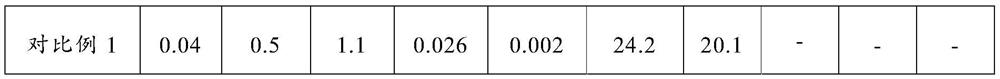

[0039] The composition of the heat-resistant austenitic stainless steel of Examples 1 to 5 in the present invention is listed in Table 2, and the manufacturing method comprises the following steps:

[0040] EAF (Electric Furnace) + AOD (Argon Oxygen Decarburization Furnace) + LF (Ladle Refining Furnace) is used for smelting, continuous casting or die casting of flat ingots, specifically: adding ferrochromium, ferronickel and scrap steel into the electric furnace for melting, and then The molten steel is poured into the AOD furnace, and the blowing and chemical composition adjustment of de-C, de-O, de-S and N-control are carried out in the AOD furnace. When the smelting composition basically meets the requirements, the molten steel is poured into the LF furnace for the final Chemical composition and molten steel temperature adjustment; through this method of electric furnace + refining outside the furnace to obtain qualified molten steel with good purity, the production cost is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com