High-efficiency cooling back plate device used for liquid crystal semiconductor film forming

A semiconductor, high-efficiency technology, applied in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problem of easy damage to the target, to improve the effect of heat exchange, improve the efficiency of heat exchange, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

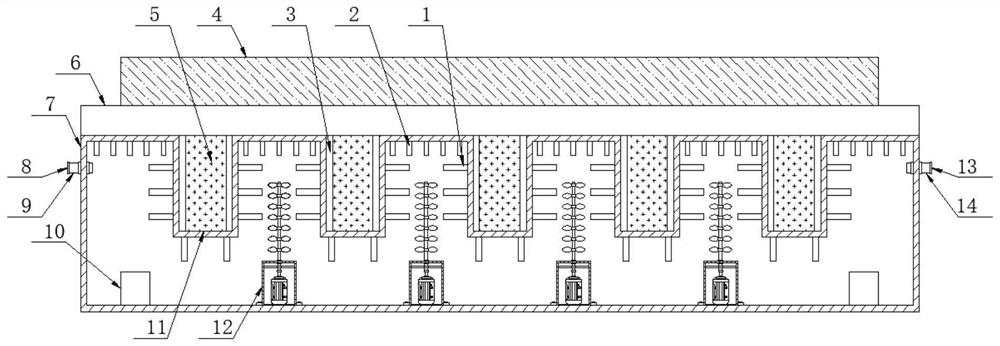

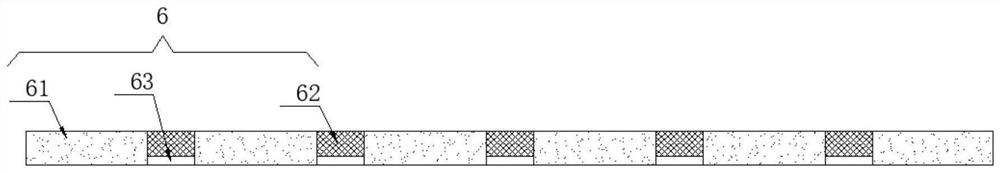

[0022] see Figure 1-4 , the present invention provides a technical solution: a high-efficiency cooling backplane device for liquid crystal semiconductor film formation, please refer to figure 1 , including a cooling backplane 6 and a cooling box 7, a target 4 is arranged above the cooling backplane 6, and the target 4 is movably connected to the cooling backplane 6, and through the cooperation between the cooling backplane 6 and the target 4, The heat on the target material 4 can be effectively transferred, and then the heat dissipation of the target material 4 can be effectively facilitated.

[0023] see figure 1 , the cooling back plate 6 is arranged above the cooling box 7, the cooling back plate 6 is movably connected with the cooling box 7, and the cooling box 7 provided can effectively facilitate the storage of cooling water, and then can effectively perform heat exchange, and then can effectively It is convenient for the target material 4 to dissipate heat, and then ...

Embodiment 2

[0031] Such as Figure 4As shown, the difference from the previous embodiment 1 is that a fixed sleeve 125 is provided above the coupling 123, and the fixed sleeve 125 is sleeved on the outer wall of the movable rod 126. Both ends of the casing 125 are fixedly connected with fixed rods 124, and the fixed rods 124 are fixedly connected with the inner wall of the box body 121. Through the cooperation between the fixed rods 124 and the fixed sleeves 125, the stability of the movable rod 126 can be effectively increased. , and then can effectively ensure that the stirring mechanism can work stably.

[0032] Such as figure 1 As shown, the top inner wall of the cooling box 7 is uniformly provided with multiple sets of fins 2, the fins 2 are fixedly connected with the cooling box 7, and the inner wall of the cooling box 7 is evenly provided with multiple sets of fins at the position matching with the permanent magnet 5 One 1, the fin one 1 is fixedly connected with the cooling box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com