Rapid centering optical element center thickness precision measuring instrument

A technology of optical components and center thickness, which is applied in the field of optical precision measurement, can solve the problems of high cost, complex structure, and easy damage of the surface, and achieve the effect of high-precision measurement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

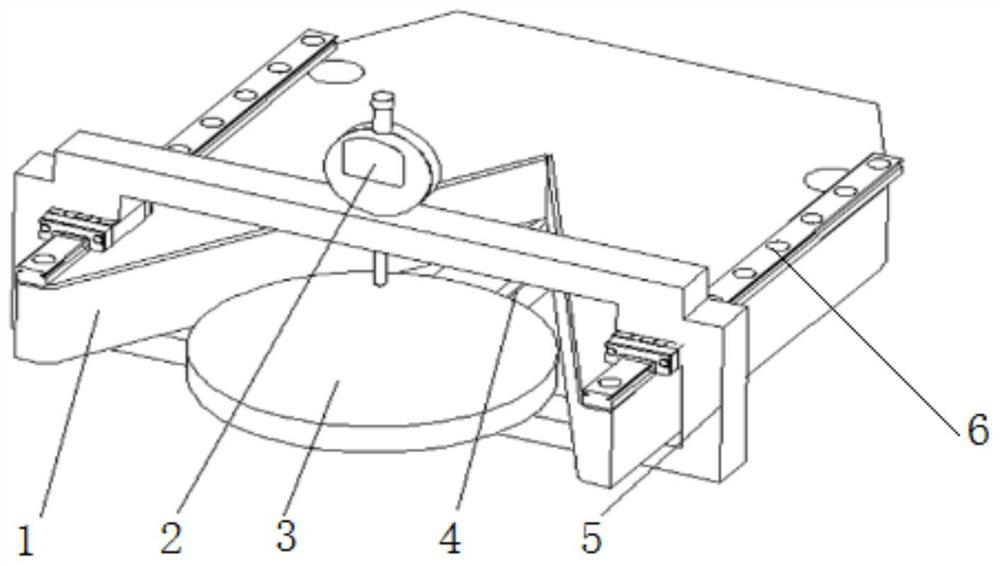

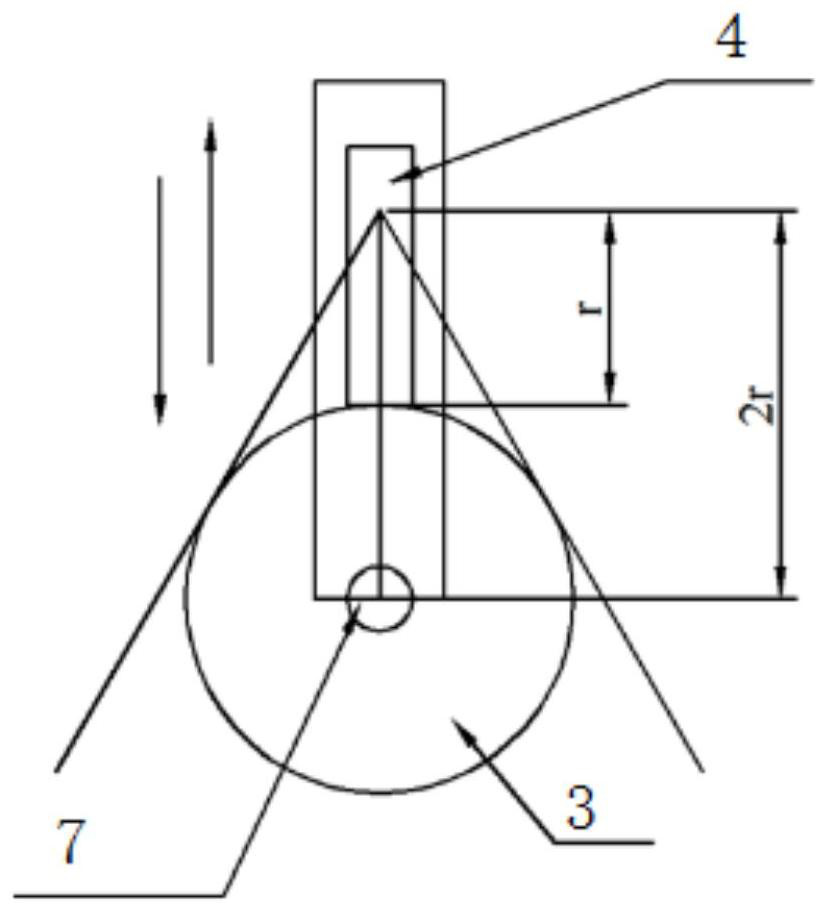

[0013] refer to figure 1 and figure 2 As shown, the optical element center thickness measuring instrument of this embodiment includes an angle plate bottom plate 1, a meter head bracket 5, a measuring ruler 4, and a meter head bracket guide rail 6; one end of the angle plate bottom plate 1 is provided with a V-shaped opening groove with a vertex angle of 60° , the lens 3 to be tested is placed at the V-shaped opening groove and is tangent to the two sides of the V-shaped opening groove; It is a rectangular frame, which is set on the bottom plate of the angle plate. The two sides of the top frame of the gauge bracket 5 cooperate with the gauge bracket guide rail 6 and can slide back and forth along the gauge bracket gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com