Visual inspection method for weld penetration depth

A technology of visual inspection and weld penetration, which is applied in the field of welding, can solve the problems of time-consuming, labor-intensive, time-consuming and money-wasting, achieve good economic value, and improve the overall product inspection and manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

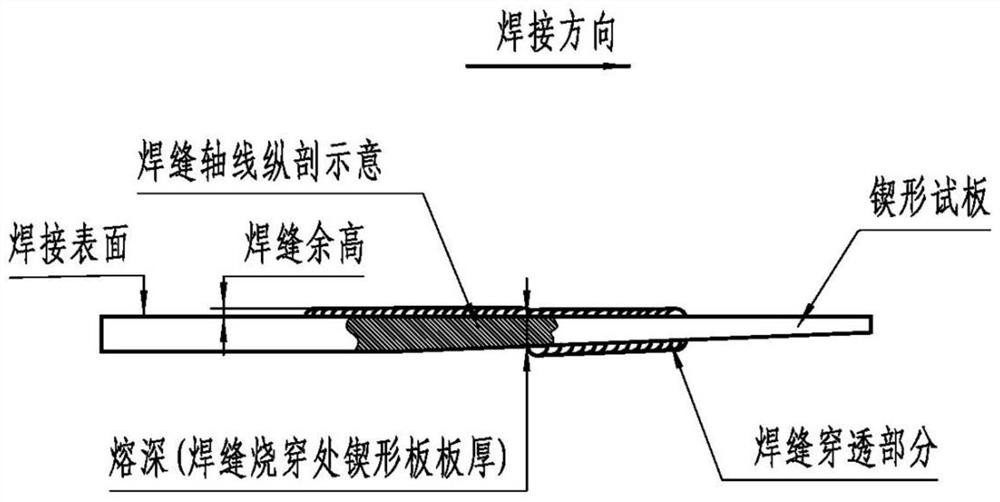

[0027] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0028] 1) First inspect the test panel.

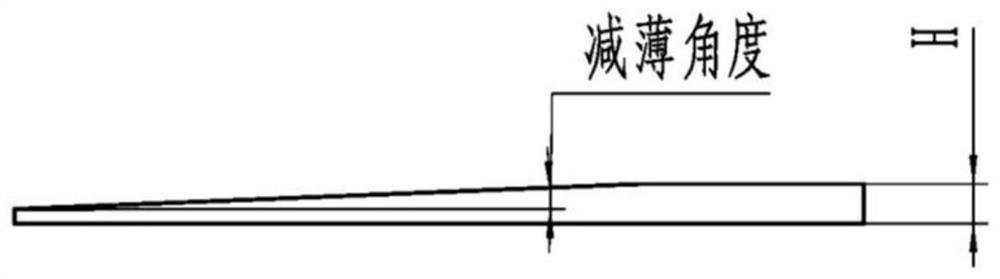

[0029] As shown in Figure 1, the test plate is a strip-shaped wedge-shaped thin plate. One end of the test plate is equal in thickness, and the thickness dimension is H. H≥the thickness of the welded joint of the product. This end of the test plate is the sample clamping part and the weld seam. The starting part; the other end of the test plate is wedge-shaped, gradually thinning along a certain angle. The angle range is 0~10°.

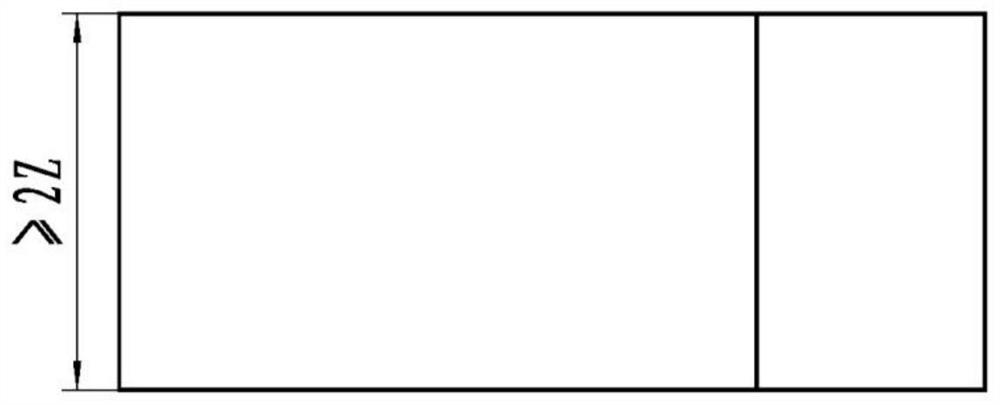

[0030] Determine whether the width of the test plate is greater than or equal to 2 times Z, and Z represents the width of the heat-affected zone of the weld.

[0031] If not, find the test board again, if yes, go to the next step.

[0032] 2) Determine the position of the weld seam

[0033] Such as figure 2 As shown, when welding, the horizontal plane (welding surface) of the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com