A kind of high water retention composite proton exchange membrane and preparation method thereof

A proton exchange membrane and composite technology, which is applied in the field of high water retention composite proton exchange membrane and its preparation, can solve the problems such as mechanical deterioration of proton exchange membranes, achieve improved water management characteristics, strengthen the limiting effect, increase Effect of outlet width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

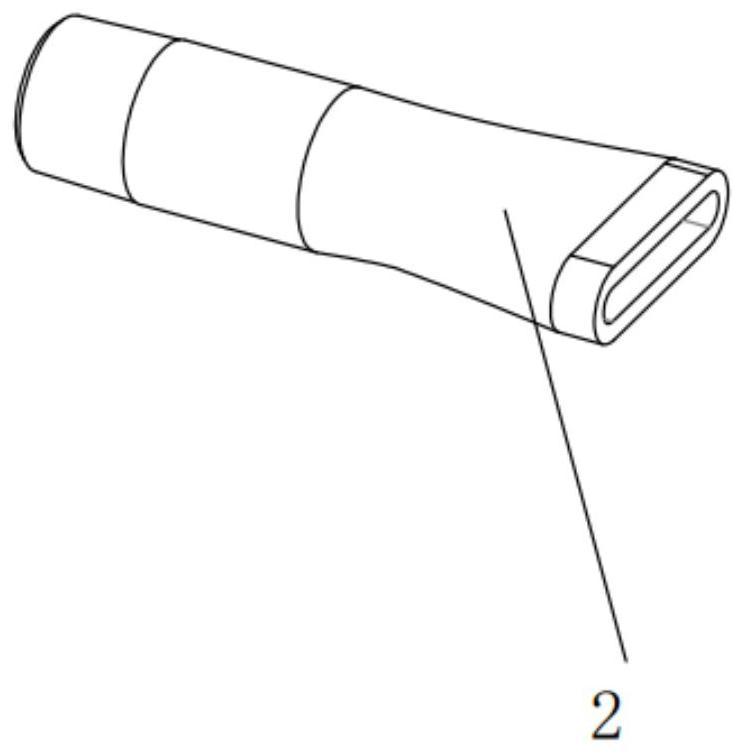

[0040] A preparation method of a high water-retention composite proton exchange membrane, the composite proton exchange membrane comprises a carbon-supported catalyst, a carbon nanofiber or carbon nanotube filling material and an ion conductor, the carbon-supported catalyst and the three-dimensional filling material are mixed and arranged, and are The ion conductor is wrapped or partially wrapped, this structure is easy to form more three-phase contacts and higher internal mass transfer space inside the catalytic layer electrode, and the thickness of the three-dimensional catalytic layer electrode is 6-50 μm;

[0041] The preparation method of the high water-retention composite proton exchange membrane is as follows:

[0042] Weigh 10 mg of lignosulfonic acid (sodium) hydrogel, disperse it into 50 mg of N,N-dimethylformamide solvent, mix uniformly, and let stand for 5 minutes, and then mechanically stir for 1.5 hours to obtain a dispersion; then Weigh 9.8g of perfluorosulfonic...

Embodiment 2

[0044] Weigh 25 mg of acrylic hydrogel, disperse it in 141.7 mg of N,N-dimethylacetamide solvent, mix it uniformly, let it stand for 10 minutes, and then mechanically stir for 2.0 h to obtain a dispersion; then weigh 2.375 g perfluorosulfonic acid resin D79 (20wt.%), which was fully mixed by magnetic stirring and ultrasonic treatment at the same time to obtain a prefabricated film solution; in the formed prefabricated film solution, the ratio of acrylic hydrogel to solvent was 15:85, acrylic acid The ratio of hydrogel-like and perfluorosulfonic acid resin is 5:95; the fully mixed membrane-forming solution is made into membrane by electrospinning method, and finally the composite proton exchange membrane obtained by spinning is placed in a drying storage box After drying treatment, the treatment time is 12h, that is, the composite proton exchange membrane with high water retention is obtained.

Embodiment 3

[0046] Weigh 5mg of lignosulfonic acid (sodium) hydrogel, disperse it in isopropanol, the mass of isopropanol is 50mg, mix evenly and let stand for 5 minutes, and then perform magnetic stirring for 2.5h to obtain a dispersion liquid ; Then weigh 2.475g perfluorosulfonic acid resin D79 (20wt.%), and disperse it in 2.475g isopropanol, after it is fully mixed (magnetic stirring), the above two dispersions are uniformly mixed by magnetic stirring method and ultrasonic method at the same time to form a prefabricated Film-forming liquid; in the pre-formed film-forming liquid, the ratio of lignosulfonic acid (sodium) hydrogel to perfluorosulfonic acid resin is 1:99; then take a clean glass film-forming plate with an effective area of 25cm 2 , using the solution casting method to spread the above-mentioned completely dispersed prefabricated membrane liquid in a glass template, and place it in a drying storage box for drying treatment for 8 hours. membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com