Tail gas recovery system and process in naphthalene flaking and packaging process

A packaging process and tail gas recovery technology, applied in the direction of dispersed particle filtration, crystallization purification/separation, hydrocarbons, etc., can solve the problems of insufficient cooling and recovery of naphthalene vapor, increase equipment cost, and difficult operating environment, so as to reduce manual operations links, save investment and land occupation, and reduce the effect of cooling burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

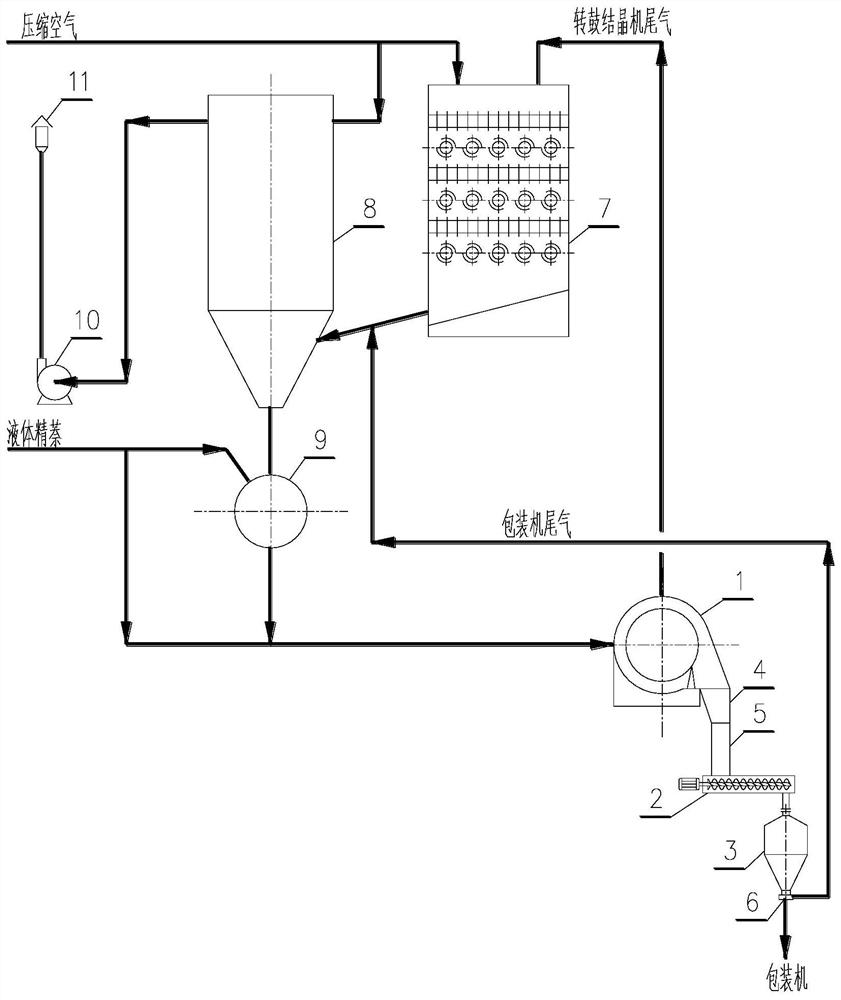

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] like figure 1 As shown, a kind of naphthalene knot sheet of the present invention, the tail gas recovery system of packaging process is characterized in that, comprises bag filter 8, tail gas fan 10, sublimation naphthalene catcher 7 and melting naphthalene groove 9; The dust gas outlet of the drum crystallizer 1 is connected to the naphthalene-containing gas inlet of the sublimation naphthalene collector 7 through the dust gas pipeline; A suction hood 6 is arranged at the inlet end of the solid fine naphthalene of the packaging machine, and the suction hood 6 is connected to the connecting pipeline through the naphthalene dust collection pipeline; Connect the tail gas release pipe, and the top of the tail gas release pipe is provided with an umbrella-shaped hood 11; the bottom of the lower hopper of the bag filter 8 is provided with a nap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com