Composite catalytic oxidation degradation method and device for organochlorine pesticide contaminated soil

A pesticide-contaminated soil and catalytic oxidation technology, applied in the field of soil remediation, can solve the problems of low removal rate, high cost of equipment introduction, lack of experience in engineering application, etc., and achieve high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

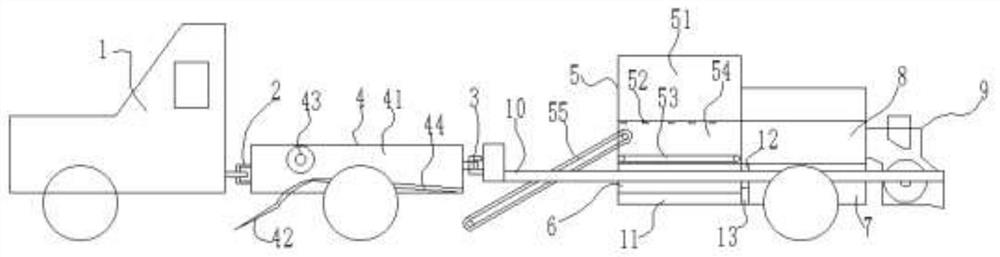

[0030] A composite catalytic oxidation degradation method for organochlorine pesticide-contaminated soil, comprising the following steps:

[0031] S1: Soil pretreatment: use tiller 4 to loosen and crush the contaminated soil first, and screen out stones, plastics and branches in the soil;

[0032] S2: Soil rinsing: use a soil remediation vehicle to shovel the soil into the leaching device 5, perform solid-liquid separation after rinsing the soil, and obtain wet soil and waste water;

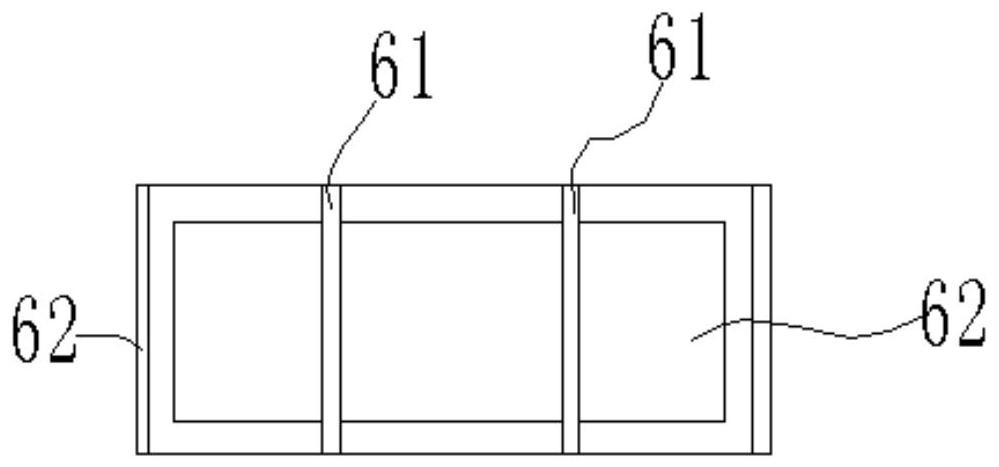

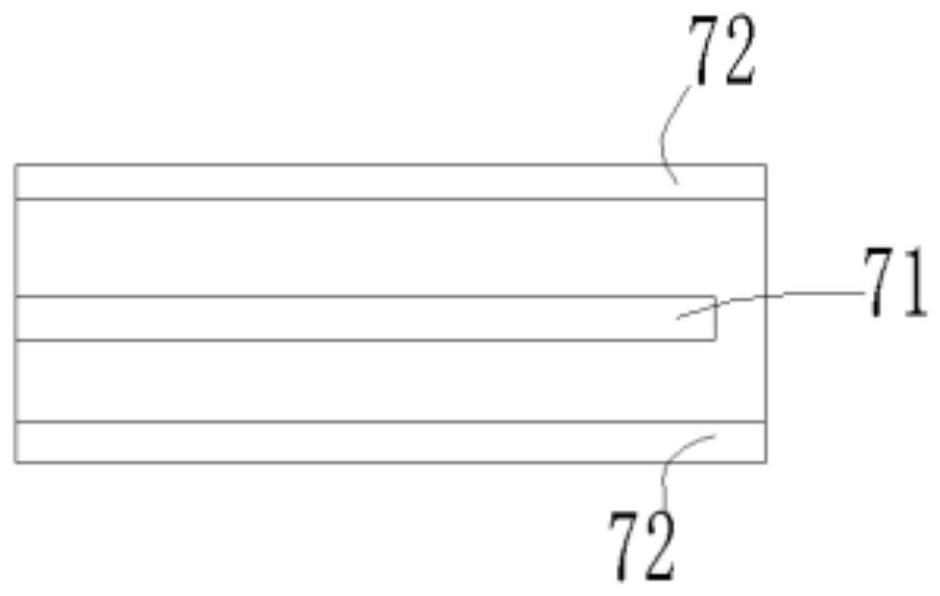

[0033] S3: Wastewater treatment: transfer the obtained waste water to the photocatalytic box 6, then adjust the pH value of the waste water to 6.5, use the nickel mesh 61 loaded with titanium dioxide as the photocatalyst, the wavelength of ultraviolet light is 240nm, the photocatalytic reaction time of waste water 1.5h, accompanied by electromagnetic stirring during the photocatalysis, the stirring speed is 80r / min, the electromagnetic power is 100W, and then the waste water is introduced into th...

Embodiment 2

[0037] A composite catalytic oxidation degradation method for organochlorine pesticide-contaminated soil, comprising the following steps:

[0038] S1: Soil pretreatment: use tiller 4 to loosen and crush the contaminated soil first, and screen out stones, plastics and branches in the soil;

[0039] S2: Soil rinsing: use a soil remediation vehicle to shovel the soil into the leaching device 5, perform solid-liquid separation after rinsing the soil, and obtain wet soil and waste water;

[0040] S3: Wastewater treatment: transfer the obtained wastewater to the photocatalytic box 6, then adjust the pH value of the wastewater to 7, use nickel mesh 61 loaded with titanium dioxide as the photocatalyst, the wavelength of ultraviolet light is 250nm, the photocatalytic reaction time of wastewater 1.8h, accompanied by electromagnetic stirring during the photocatalysis, the stirring speed is 80r / min, the electromagnetic power is 100W, and then the waste water is introduced into the ultraso...

Embodiment 3

[0044] A composite catalytic oxidation degradation method for organochlorine pesticide-contaminated soil, comprising the following steps:

[0045] S1: Soil pretreatment: use tiller 4 to loosen and crush the contaminated soil first, and screen out stones, plastics and branches in the soil;

[0046] S2: Soil rinsing: use a soil remediation vehicle to shovel the soil into the leaching device 5, perform solid-liquid separation after rinsing the soil, and obtain wet soil and waste water;

[0047] S3: Wastewater treatment: transfer the obtained waste water to the photocatalytic box 6, then adjust the pH value of the waste water to 7.5, use the nickel mesh 61 loaded with titanium dioxide as the photocatalyst, the wavelength of ultraviolet light is 256nm, the photocatalytic reaction time of waste water 2h, with electromagnetic stirring during the photocatalysis period, the stirring speed is 80r / min, the electromagnetic power is 100W, and then the waste water is introduced into the ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com