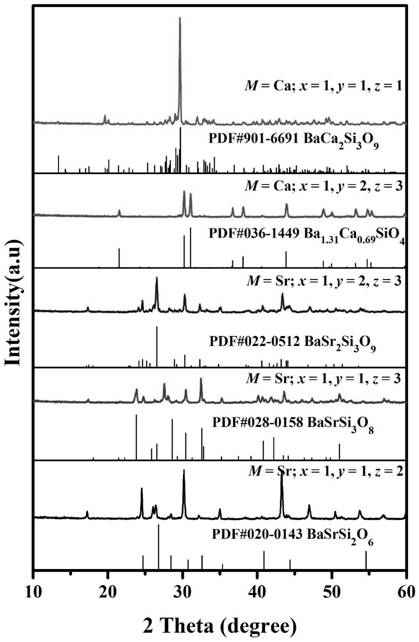

Silicon-based low-dielectric microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic and silicon-based technology, applied in the field of microwave dielectric ceramics, can solve the problems of increased system loss and heat generation, and poor system stability, and achieve the effects of stable performance, low dielectric constant, and excellent quality factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

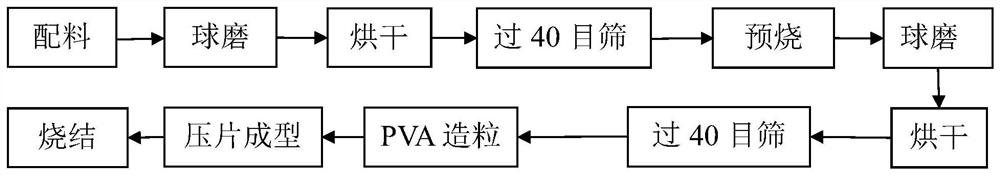

[0035] A microwave dielectric ceramic, its preparation method is carried out according to the following steps:

[0036] (1) Analytical pure BaCO 3 , CaCO 3 , SrCO 3 and SiO 2 After mixing according to the stoichiometric ratio, use zirconium balls as the medium and deionized water as the dispersant, and use a ball mill to mix and stir the powder for 5 hours at a speed of 360r / min; dry the obtained slurry at 1050°C Pre-fired for 5 hours to obtain a pre-fired ceramic powder;

[0037] (2) The pre-fired ceramic powder obtained in step (1) is subjected to wet ball milling again, the dispersant is deionized water, and after drying, 8 wt% polyvinyl alcohol (PVA) binder is added to the dried powder Granulate, and press it into a cylindrical green sample with a thickness-to-diameter ratio of 0.4 to 0.6 under a pressure of 150 MPa; after tableting, sinter in air at 1150°C to 1250°C for 5 hours to obtain the Microwave dielectric ceramics.

[0038] Table 1 Examples 1-5, sintering tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com