High-dielectric-constant ceramic dielectric material and preparation method thereof

A high dielectric constant, ceramic dielectric technology, applied in the field of ceramic dielectric materials, can solve the problems of low dielectric constant, high sintering temperature and high loss, and achieve the effect of high dielectric constant, low dielectric loss and stable temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

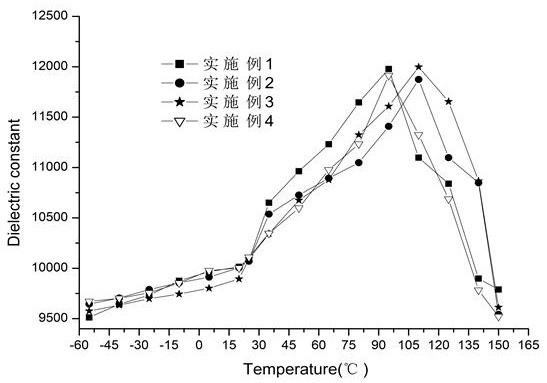

Examples

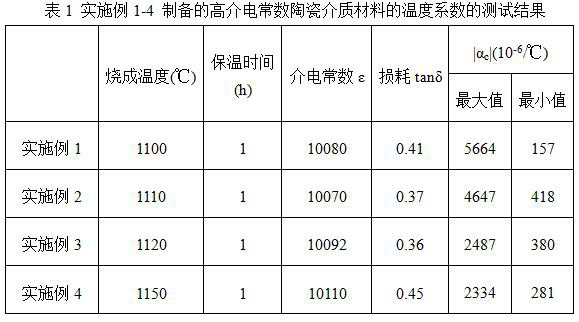

Embodiment 1

[0027] A high dielectric constant ceramic dielectric material, made of 10% BaSiO by mass percentage 3 Glass-ceramic and 90% BaO-5.75Fe 2 o 3 -0.5NiO composition.

[0028] The method for preparing described high dielectric constant ceramic dielectric material, the steps are as follows: raw material Ba(NO 3 ) 2 , Fe(NO 3 ) 3 and Ni(NO 3 ) 2 According to the chemical formula BaO-5.75Fe 2 o 3 -0.5NiO, batched, ball milled on a ball mill with a speed of 400r / min for 6 hours, dried in a 3.3kw ordinary oven at 100°C for 4 hours, and passed through 250 holes / cm 2 Sieve the sample, raise the temperature to 800°C at 5°C / min, and keep the temperature at 800°C for 3 hours to obtain frit A.

[0029] Raw material BaCO 3 and SiO 2 According to the chemical formula BaSiO 3 , for batching, ball milling on a ball mill with a speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C for 4 hours, passing through 250 holes / cm 2 Sampling sieve, heat up to 1400°C, keep wa...

Embodiment 2

[0032] A high dielectric constant ceramic dielectric material, composed of 15% BaSiO by mass percent 3 Glass-ceramic and 85% BaO-5.75Fe 2 o 3 -0.5NiO composition.

[0033] The method for preparing described high dielectric constant ceramic dielectric material, the steps are as follows: raw material Ba(NO 3 ) 2 , Fe(NO 3 ) 3 and Ni(NO 3 ) 2 According to the chemical formula BaO-5.75Fe 2 o 3 -0.5NiO, batching, ball milling on a ball mill with a speed of 400r / min for 5 hours, drying in a 3.3kw ordinary oven at 100°C for 5 hours, passing through 200 holes / cm 2 Sieve the sample, raise the temperature to 800°C at 7°C / min, and keep it at 800°C for 2 hours to obtain frit A.

[0034] Raw material BaCO 3 and SiO2 According to the chemical formula BaSiO 3 , for batching, ball milling on a ball mill with a speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C for 4 hours, passing through 250 holes / cm 2 Sampling sieve, heat up to 1400°C, keep warm for 2 hours...

Embodiment 3

[0037] A high dielectric constant ceramic dielectric material, composed of 20% BaSiO by mass percentage 3 Glass-ceramic and 80% BaO-5.75Fe 2 o 3 -0.5NiO composition.

[0038] The method for preparing described high dielectric constant ceramic dielectric material, the steps are as follows: raw material Ba(NO 3 ) 2 , Fe(NO 3 ) 3 and Ni(NO 3 ) 2 According to the chemical formula BaO-5.75Fe 2 o 3 -0.5NiO, batching, ball milling on a ball mill with a speed of 400r / min for 4 hours, drying in a 3.3kw ordinary oven at 100°C for 5 hours, passing through 120 holes / cm 2 Sieve the sample, raise the temperature to 800°C at 10°C / min, and keep it at 800°C for 4 hours to obtain frit A.

[0039] Raw material BaCO 3 and SiO 2 According to the chemical formula BaSiO 3 , for batching, ball milling on a ball mill with a rotational speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C for 4 hours, passing through 200 holes / cm 2 Sampling sieve, heat up to 1400°C, keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com