Composite radiator aluminum alloy material and preparation method thereof

A technology of aluminum alloy material and radiator, applied in the field of radiator aluminum alloy, can solve the problems of rough surface of the radiator, poor thermal conductivity, large volume, etc., and achieve the effects of wide utilization value, enhanced corrosion resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

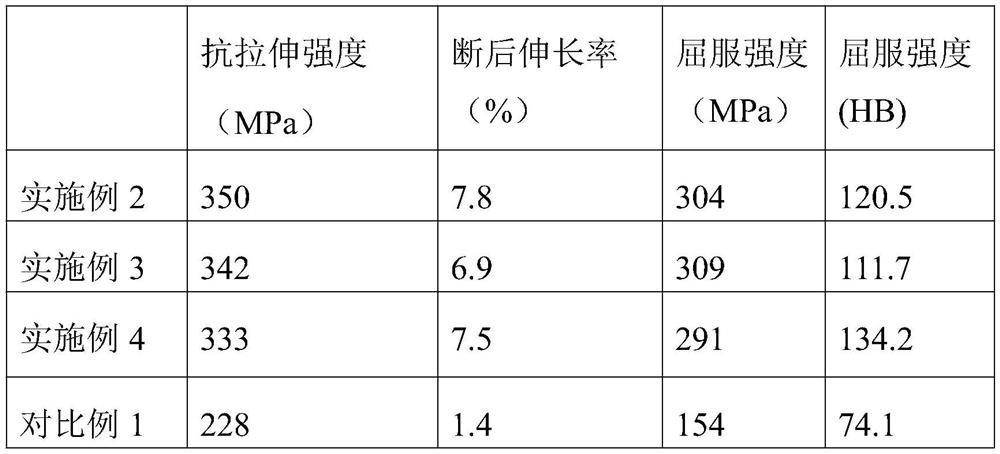

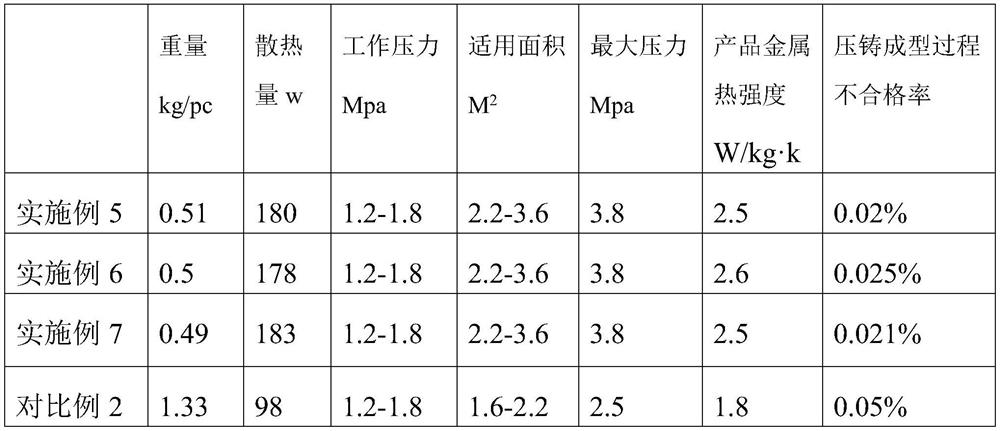

Examples

Embodiment 1

[0025]A composite radiator aluminum alloy material, comprising the following components expressed in parts by weight: 12.2-13.3 parts of Si, 2.6-2.8 parts of Cu, 0.4-0.5 parts of Mg, 0.1-0.25 parts of Mn, 0.01 -0.023 parts of Sn, 0.03-0.05 parts of Ni, 0.7-1.1 parts of Zn, 0.8-0.95 parts of Fe, 0.03-0.04 parts of Pb, 0.001-0.0015 parts of Cd, 0.001-0.002 parts of Ca, 0.0001- 0.0005 parts of Nd, 0.0004-0.0023 parts of Dy, 0.001-0.0037 parts of Pr, 0.0023-0.0115 parts of Er, 0.0009-0.0075 parts of Lu, 0.07-0.1 parts of K, 0.1-0.15 parts of Ba, and 81.5-87.6 parts Al. Silicon is the main element to improve the fluidity of liquid aluminum alloys. Good fluidity can be obtained from eutectic to hypereutectic, but the precipitated silicon after crystallization is relatively coarse, easy to form hard spots, lower elongation, and poor machinability; Magnesium can improve the corrosion resistance of products and inhibit intergranular corrosion. Aluminum-magnesium alloys have good corro...

Embodiment 2

[0032] A composite radiator aluminum alloy material, comprising the following components expressed in parts by weight: 12.2 parts of Si, 2.6 parts of Cu, 0.4 parts of Mg, 0.1 parts of Mn, 0.01 parts of Sn, 0.04 parts of Ni , 0.7 parts of Zn, 0.9 parts of Fe, 0.04 parts of Pb, 0.0012 parts of Cd, 0.002 parts of Ca, 0.0001 parts of Nd, 0.0004 parts of Dy, 0.003 parts of Pr, 0.0112 parts of Er, 0.0009 parts of Lu , 0.08 parts of K, 0.15 parts of Ba and 82 parts of Al.

[0033] A method for preparing a composite radiator aluminum alloy material, comprising the following steps:

[0034] Step 1: Melting and casting an aluminum alloy ingot, the mass percentage of the chemical composition in the aluminum alloy ingot is:

[0035] 0.4 parts of Mg, 0.1 parts of Mn, 0.01 parts of Sn, 0.04 parts of Ni, 0.04 parts of Pb, 0.0012 parts of Cd, 0.002 parts of Ca, 0.0001 parts of Nd, 0.0004 parts of Dy, 0.003 parts of Pr, 0.0112 parts of Er, 0.0009 parts of Lu, 0.08 parts of K, 0.15 parts of B...

Embodiment 3

[0039] A composite radiator aluminum alloy material, comprising the following components expressed in parts by weight: 13.3 parts of Si, 2.8 parts of Cu, 0.5 parts of Mg, 0.25 parts of Mn, 0.02 parts of Sn, 0.05 parts of Ni , 1.1 parts of Zn, 0.95 parts of Fe, 0.03 parts of Pb, 0.0015 parts of Cd, 0.002 parts of Ca, 0.0001 parts of Nd, 0.0023 parts of Dy, 0.001 parts of Pr, 0.0115 parts of Er, 0.0075 parts of Lu , 0.1 parts of K, 0.1 parts of Ba and 87.6 parts of Al.

[0040] A method for preparing a composite radiator aluminum alloy material, comprising the following steps:

[0041] Step 1: Melting and casting an aluminum alloy ingot, the mass percentage of the chemical composition in the aluminum alloy ingot is:

[0042] 0.5 parts of Mg, 0.25 parts of Mn, 0.02 parts of Sn, 0.05 parts of Ni, 1.1 parts of Zn, 0.03 parts of Pb, 0.0015 parts of Cd, 0.002 parts of Ca, 0.0001 parts of Nd, 0.0023 parts of Dy, 0.001 parts of Pr, 0.0115 parts of Er, 0.0075 parts of Lu, 0.1 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com