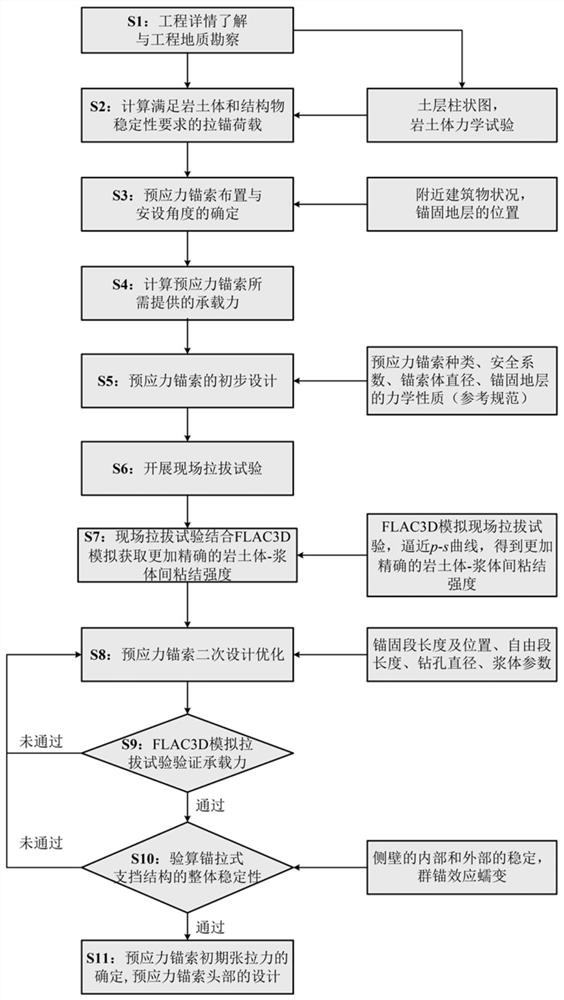

Design optimization method for pre-stressed anchor cable in anchoring type retaining structure

A technology of prestressed anchor cable and retaining structure, applied in the field of geotechnical engineering, can solve the problems of too large anchoring length, too conservative design, contrary to the concept of high-quality development, etc., so as to reduce the project cost and reduce the number of times. , the effect of optimizing the design scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

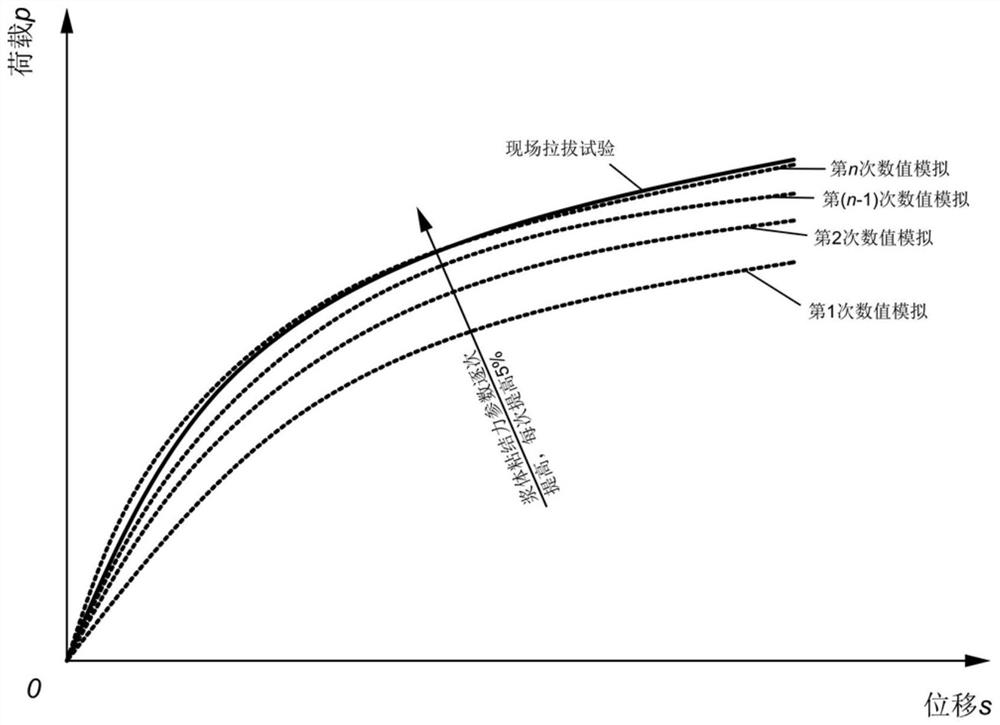

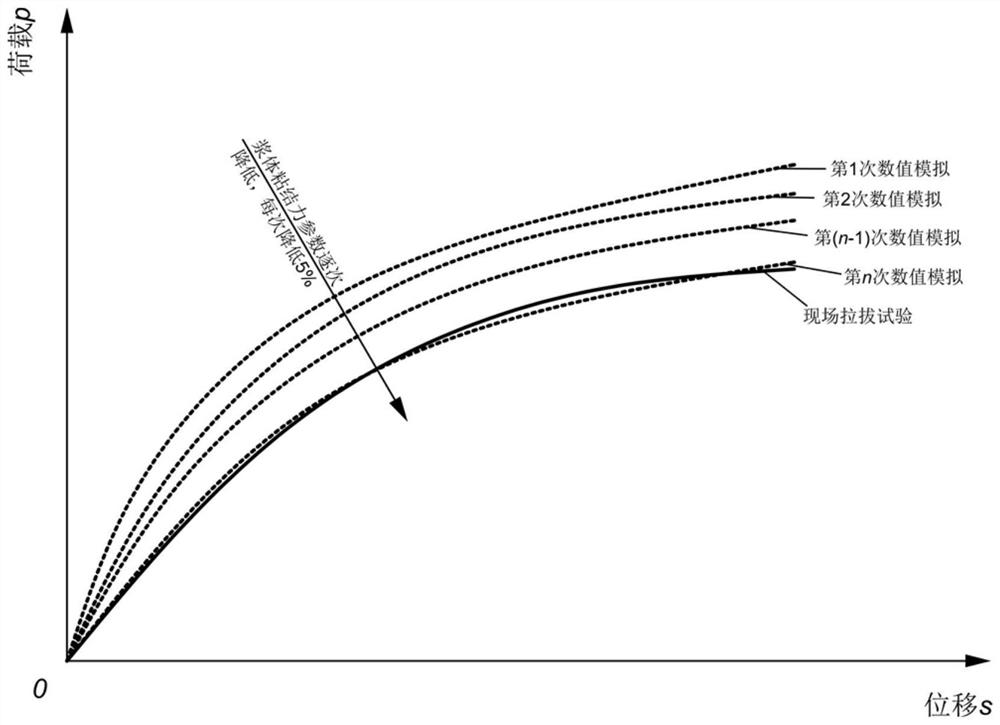

Method used

Image

Examples

Embodiment

[0042] A design optimization method for prestressed anchor cables in anchor-tensioned ground walls in sandy pebble formations.

[0043] Step 1: Understanding of project details and engineering geological survey; the project is the dry dock foundation pit of the immersed tube tunnel in the Yuliangzhou section of the east-west axis road project in Xiangyang City. The excavation depth of the foundation pit is 10.75m, and the foundation pit enclosure structure is anchored The ground connects the wall; the stratum is divided into three layers from top to bottom: silt layer, fine sand layer, and pebble layer, and their thicknesses are 3m, 7m, and 10m respectively; the physical and mechanical parameters of the soil layer are shown in Table 1.

[0044] Table 1 Soil Layer Parameters

[0045]

[0046] Step 2: Using the elastic fulcrum method to calculate the anchor load that meets the stability requirements of rock and soil and structures is 453.2kN;

[0047] Step 3: Determine the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com