Cleaning method of polyacrylonitrile carbon fiber precursor drying and densifying equipment

A technology of polyacrylonitrile carbon fiber and cleaning method, which is applied in the direction of cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc., can solve the problem of poor cleaning effect, unsafe cleaning process, and appearance of densification equipment surface burrs and other problems, to achieve a good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

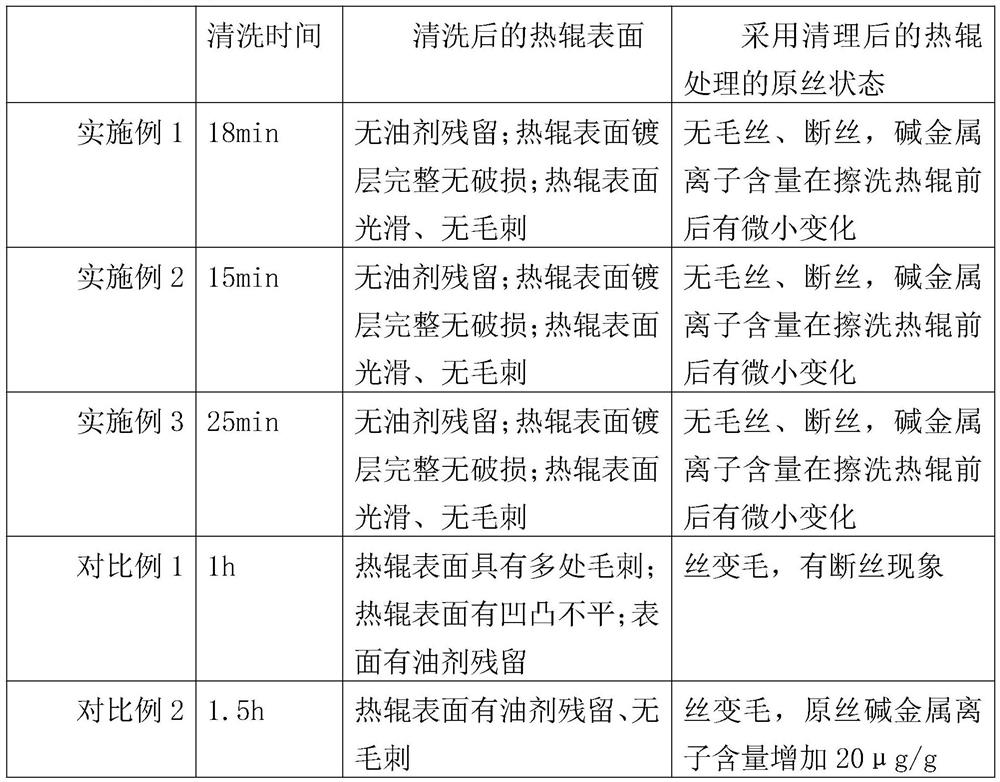

Embodiment 1

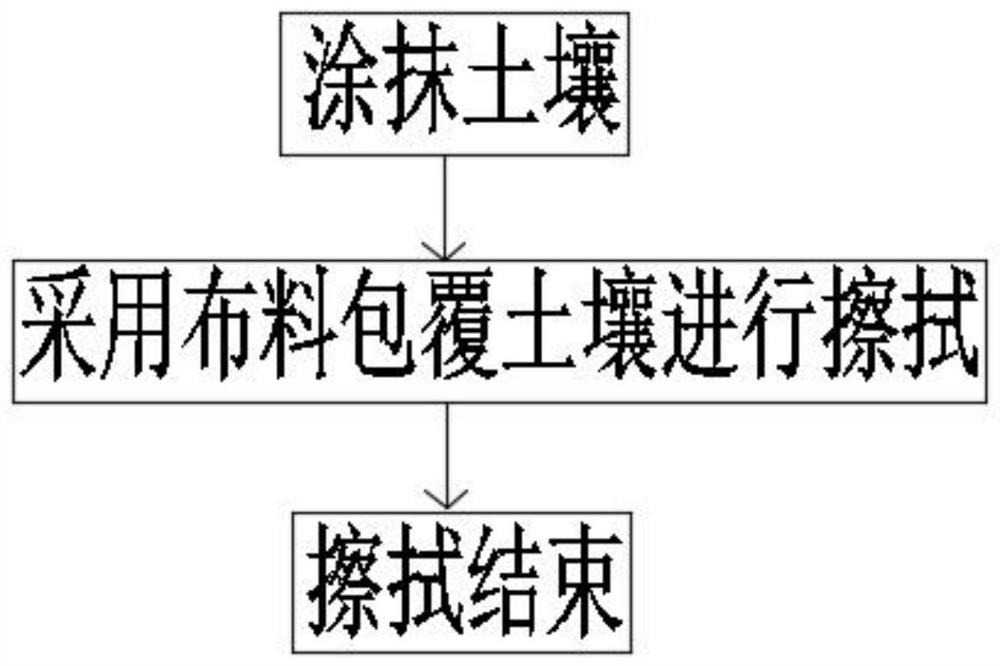

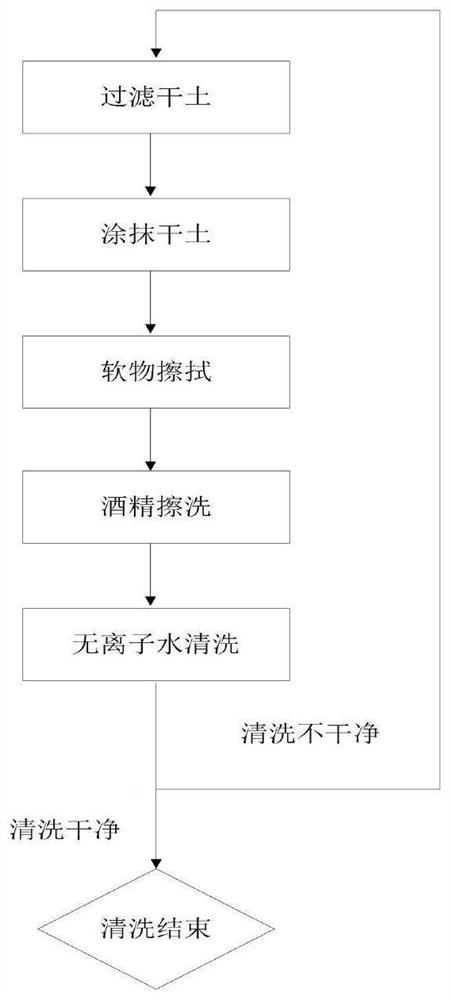

[0052] The drying and densification hot roller cleaning method for polyacrylonitrile carbon fiber precursor production comprises the steps:

[0053] (1) Filter the loam soil with a water content of 3% and an organic matter content of 1% with a 200-mesh filter, and when the temperature of the hot roller drops to 45°C, apply the filtered dry soil to the surface of the wiped hot roller .

[0054] (2) Wipe the hot roller repeatedly with gauze to remove the deposits adhering to the hot roller.

[0055] (3) Soak the gauze in 30% alcohol solution at room temperature, and then repeatedly scrub the hot roller with the soaked gauze.

[0056] (4) Soak the gauze in ion-free water at 25°C, and then use the soaked gauze to repeatedly scrub the hot roller until it is clean.

Embodiment 2

[0058] The drying and densification hot roller cleaning method for polyacrylonitrile carbon fiber precursor production comprises the steps:

[0059] (1) Filter the clayey soil with a water content of 20% and an organic matter content of 10% with a 300-mesh filter, reduce the temperature of the hot roller to 50°C, and apply the filtered dry soil to the surface of the wiped hot roller .

[0060] (2) Wipe the hot roller repeatedly with gauze to remove the deposits adhering to the hot roller.

[0061] (3) Soak the gauze in 40% alcohol solution at room temperature, and then repeatedly scrub the hot roller with the soaked gauze.

[0062] (4) Soak the gauze in 30°C ion-free water, then repeatedly scrub the hot roller with the soaked gauze until it is clean.

Embodiment 3

[0064] The drying and densification hot roller cleaning method for polyacrylonitrile carbon fiber precursor production comprises the steps:

[0065] (1) Filter the loam soil with 10% water content and 5% organic matter content with a 100-mesh filter, reduce the temperature of the hot roll to 40°C, and apply the filtered dry soil to the surface of the hot roll to be wiped.

[0066] (2) Wipe the hot roller repeatedly with gauze to remove the deposits adhering to the hot roller.

[0067] (3) At room temperature, soak the gauze in 35% alcohol solution, and then repeatedly scrub the hot roller with the soaked gauze.

[0068] (4) Soak the gauze in 40°C ion-free water, then repeatedly scrub the hot roller with the soaked gauze until it is clean.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com