Lens protection equipment of metal 3D printer

A technology of 3D printer and protection equipment, applied in the field of 3D printing, can solve the problems of lens explosion, powder pollution, insufficient power, etc., and achieve the effect of preventing black smoke pollution, good sealing performance, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

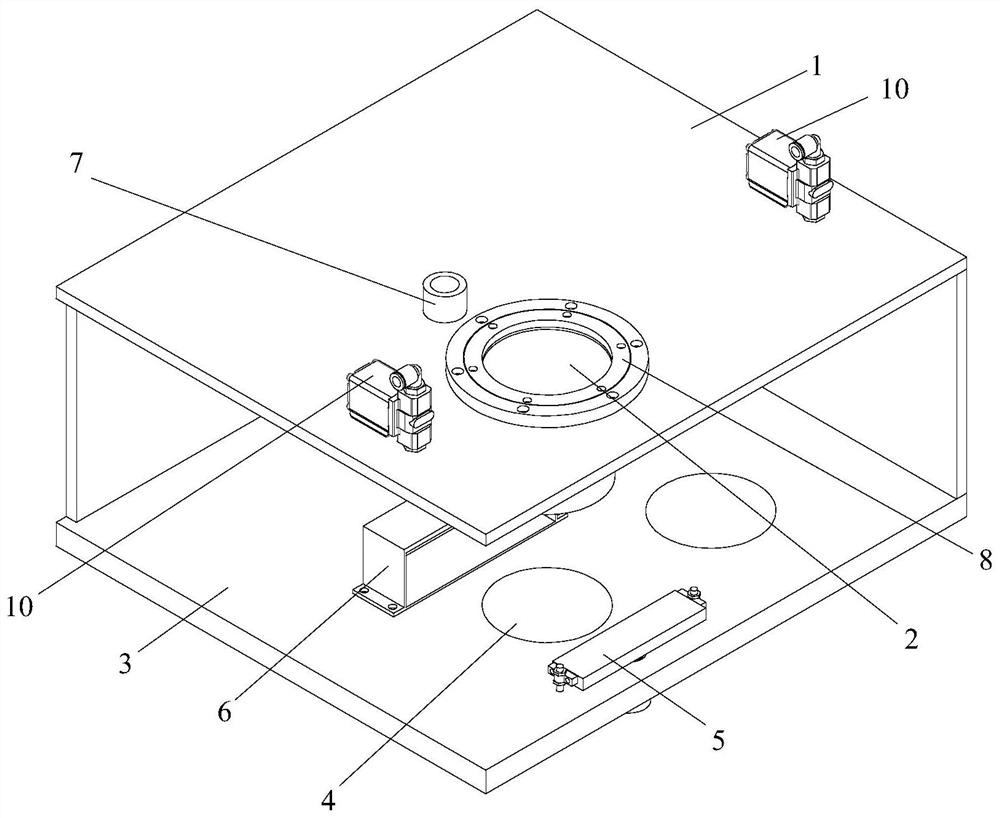

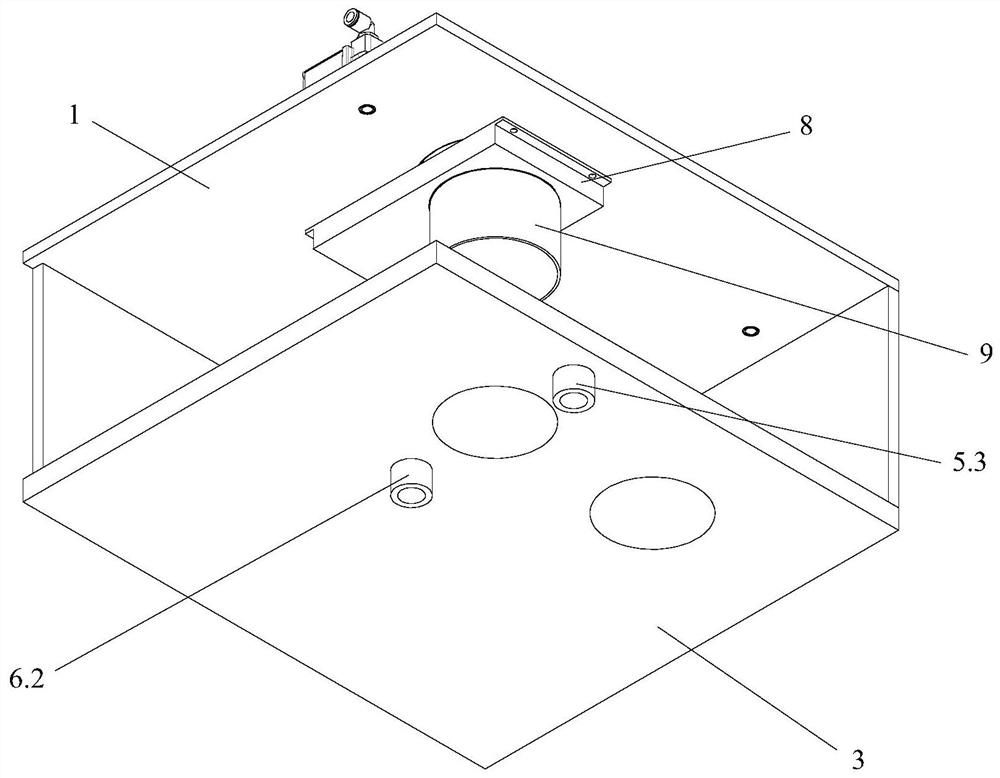

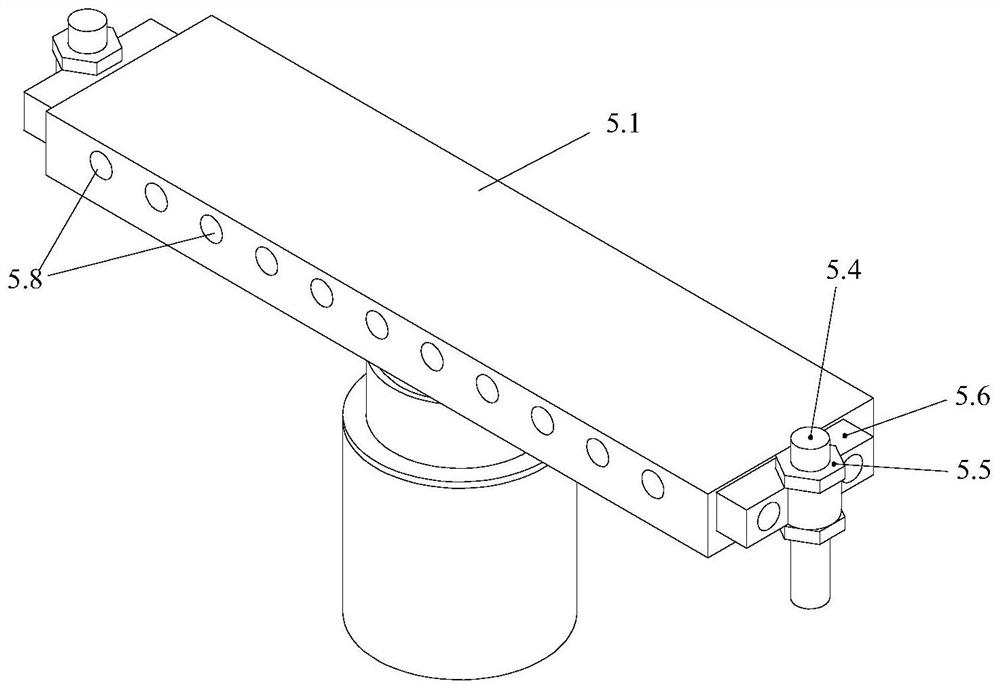

[0043] like Figure 1 to Figure 6 As shown, the lens protection device of the metal 3D printer of the present invention is arranged on the molding chamber, the top plate 1 of the molding chamber is provided with a lens 2, and the bottom plate 3 of the molding chamber below the lens 2 is used as the molding surface 4 of the lens; the lens protection The equipment includes a blower (not shown), a bottom air intake mechanism 5, a solenoid valve 10 for respectively controlling argon and exhaust, an exhaust mechanism 6 for inhaling and purifying polluted gases, and a lens protection mechanism, wherein , The lens protection mechanism includes a top air intake pipe 7, a lens protection device 8 and a guide cylinder 9 connected in sequence. The lens protector 8 is connected with the lens 2, the top air inlet pipe 7 is arranged on the top plate 1 of the molding chamber, the bottom air inlet mechanism 5 and the exhaust mechanism 6 are all arranged on the bottom plate 3 of the molding ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com