Automatic artificial board processing system and artificial board production process

An automatic processing, wood-based panel technology, applied in the direction of manufacturing tools, presses, material forming presses, etc., can solve the problems of complicated and troublesome operation process, low work efficiency, time-consuming and laborious, etc., so as to reduce labor costs and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

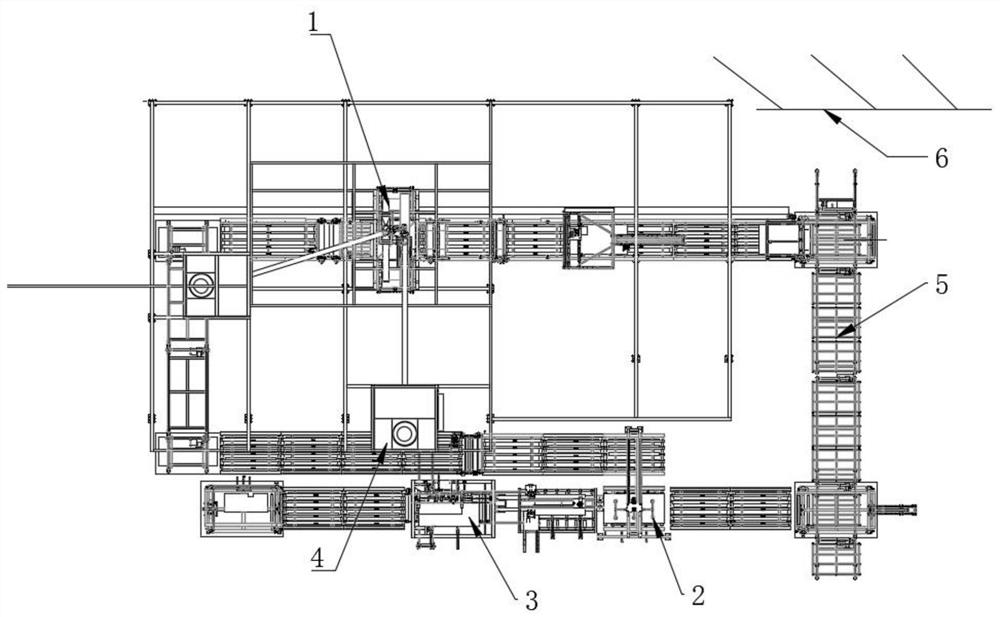

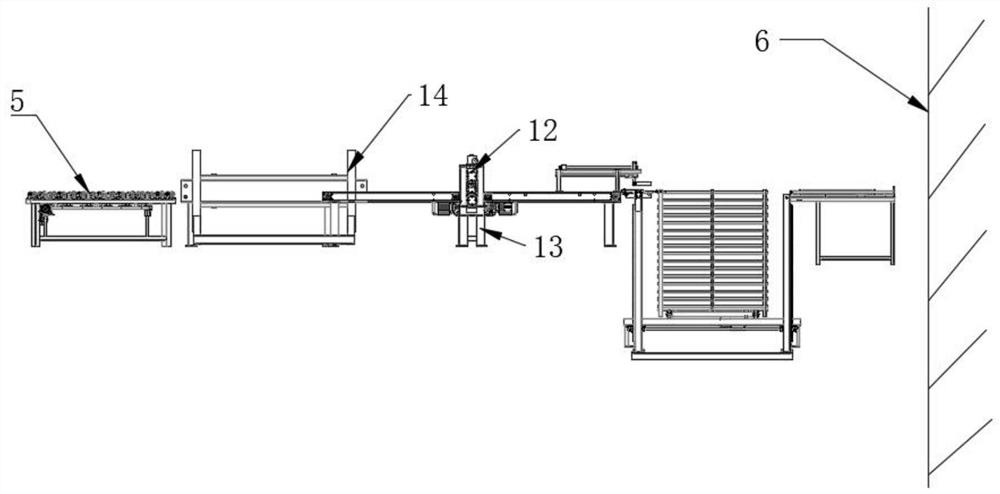

[0038] Embodiment 1: A kind of wood-based panel automatic processing system, see Figure 1 to Figure 4 , including a feeding mechanism 1, which is injected on the light template after mixing a certain concentration of the mixture by stirring and mixing the raw materials;

[0039] Maintenance workshop 6, air-drying the mixture injected on the light template;

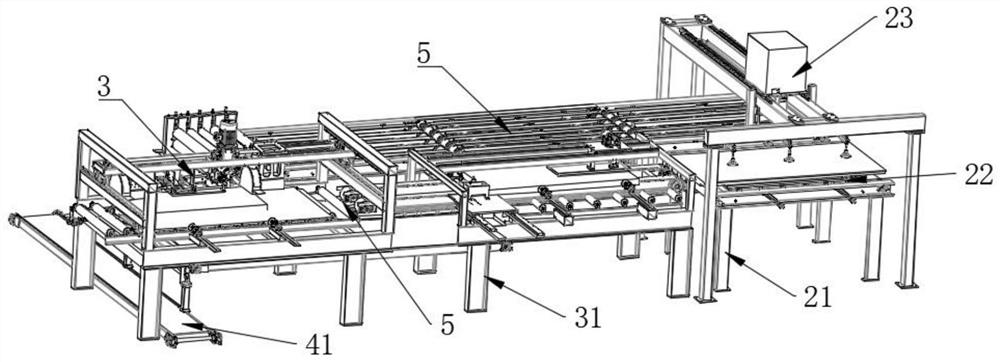

[0040] The extruding mechanism 11 is used to press the surface after forming a plate through the air-dried mixture;

[0041] The demoulding mechanism 2 separates the light template from the plate;

[0042] Cutting mechanism 3, preset opening according to the required keyhole size and requirements;

[0043] The recovery mechanism 4 collects the trimmed leftovers and fines, and communicates with the feeding mechanism 1;

[0044] A conveying track 5 is set in a closed circuit, the feeding mechanism 1, the demoulding mechanism 2 and the cutting mechanism 3 are respectively arranged on the conveying track 5, the maintenance...

Embodiment 2

[0066] Embodiment 2: A wood-based panel production process, including the above-mentioned wood-based panel automatic processing system, and also includes S1 feeding and injection molding: pouring the raw materials with a good ratio into the feeding mechanism 1, and continuously feeding through the feeding mechanism 1 The light template completes the injection molding;

[0067] S2 Initial cooling and initial air-drying: the finished bare formwork is transported from the feeding mechanism 1 to the maintenance workshop 6 through the conveying track 5, and the initial cooling and initial air-drying are performed in the maintenance workshop 6, so that the mixture in the light formwork forms a plate;

[0068] S3 Extrusion forming: the light template after being air-dried is transported to the extrusion mechanism 11 by the conveying track 5, and the surface of the plate is extruded by the extrusion mechanism 11;

[0069] S4 secondary cooling and secondary air-drying: the extruded pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com