One-way moisture guiding polylactic acid woven fabric and preparation method thereof

A moisture-conducting polylactic acid machine and polylactic acid fiber technology, applied in chemical instruments and methods, dyeing methods, textiles and papermaking, etc., can solve problems such as deformation and shrinkage, not bright enough fabrics, poor antibacterial properties, etc. Bright, strong color fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

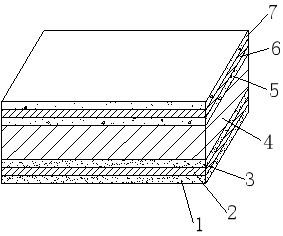

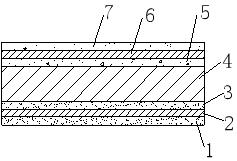

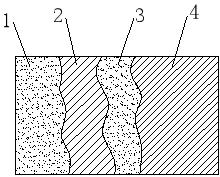

Image

Examples

preparation example Construction

[0037] Further, a method for preparing a unidirectional moisture-conducting polylactic acid woven fabric, the preparation method includes the following steps:

[0038] 1. Embryo weaving: The knitting needles used for weaving embryos are A-grade knitting needles. The specific process conditions are: the number of needles is 25G, the opening is 35 inches, the total number of needles is 2011G, and the thread lengths are 40cm / 100G and 30cm in order. / 100G, 17cm / 100G;

[0039] 2. Dyeing and finishing: Dyeing and finishing includes boiling, bleaching, wool feeding, dyeing, cleaning and soaping, neutralization, and hydrophilic soft oil treatment before moisture absorption and perspiration;

[0040] 3. Dehydration and drying: use the coating machine to dehydrate and dry the dyed gray cloth, and roll it while unwinding;

[0041] Fourth, rough edge finishing;

[0042] 5. Finished product setting: Finished product setting is carried out in a medium containing 0.2kgTR-1062 and 5kg setti...

Embodiment 1

[0050] A kind of preparation method of unidirectional moisture guide polylactic acid woven fabric, described preparation method comprises the steps:

[0051]1. Embryo weaving: The knitting needles used for weaving embryos are A-grade knitting needles. The specific process conditions are: the number of needles is 25G, the opening is 35 inches, the total number of needles is 2011G, and the thread length is 40cm / 100G;

[0052] 2. Dyeing and finishing: Dyeing and finishing includes boiling, bleaching, wool feeding, dyeing, cleaning and soaping, neutralization, and hydrophilic soft oil treatment before moisture absorption and perspiration;

[0053] 3. Dehydration and drying: use the coating machine to dehydrate and dry the dyed gray cloth, and roll it while unwinding;

[0054] Fourth, rough edge finishing;

[0055] 5. Finished product setting: Finished product setting is carried out in a medium containing 0.2kgTR-1062 and 5kg setting agent, the setting temperature is 145°C, and th...

Embodiment 2

[0063] A kind of preparation method of unidirectional moisture guide polylactic acid woven fabric, described preparation method comprises the steps:

[0064] 1. Embryo weaving: The knitting needles used for weaving embryos are A-grade knitting needles. The specific process conditions are: the number of needles is 25G, the opening is 35 inches, the total number of needles is 2011G, and the thread length is 30cm / 100G;

[0065] 2. Dyeing and finishing: Dyeing and finishing includes boiling, bleaching, wool feeding, dyeing, cleaning and soaping, neutralization, and hydrophilic soft oil treatment before moisture absorption and perspiration;

[0066] 3. Dehydration and drying: use the coating machine to dehydrate and dry the dyed gray cloth, and roll it while unwinding;

[0067] Fourth, rough edge finishing;

[0068] 5. Finished product setting: Finished product setting is carried out in a medium containing 0.2kgTR-1062 and 5kg setting agent, the setting temperature is 148°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com