Deep development and utilization method for glauberite ore mining waste rocks

A glauberite and waste rock technology, which is applied in the field of glauberite resource utilization, can solve the problem that the mining waste rock has not been effectively utilized as resources, and achieves the effects of low production cost, improved economic benefit, and high conversion and utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

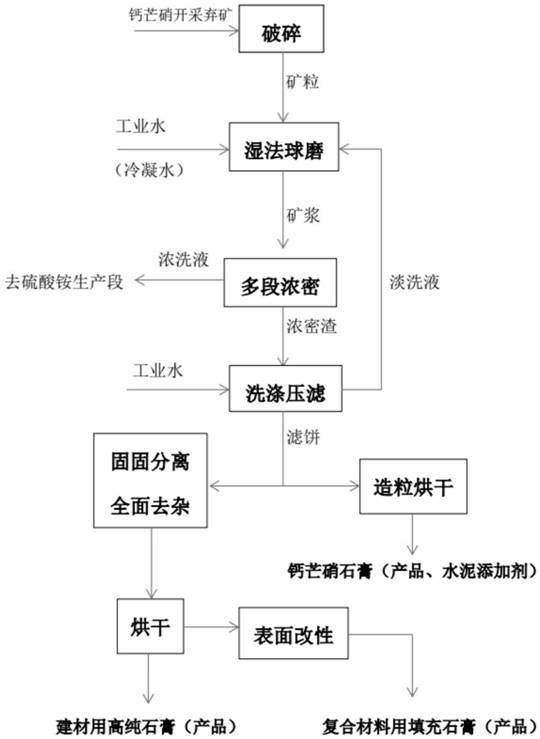

[0040] A method for deep development and utilization of glauberite mining waste rocks, comprising the following steps:

[0041] (1) Crushing the waste rock produced by glauberite mining to make glauberite particles, the particle size of the obtained glauberite particles is less than 35mm;

[0042] (2) Send the prepared Glauberite ore particles into a wet ball mill, perform wet ball milling, and prepare Glauberite slurry through the wet ball mill, and the particle size of the Glauberite slurry in the prepared Glauberite slurry is less than 0.50mm;

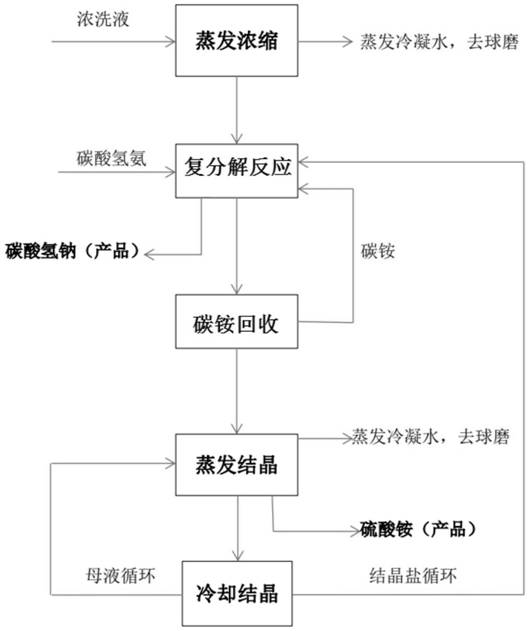

[0043] (3) The prepared glauberite pulp is sent to the multi-stage dense washing section by the pulp pump for countercurrent washing. The thickened mud is transferred downstream by the mud pump, and the dense washing liquid is transferred countercurrently by the brine pump. The raw liquid of the dense washing liquid Ordinary industrial water can be used. When the dense lotion flows back to the first stage, control the amount of conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com