Preparation method of high-strength and high-toughness vinyl ester resin

A vinyl ester resin, high-strength technology, applied in the field of vinyl ester resin, can solve the problems of affecting stability, large curing shrinkage, easy gelation, etc., to achieve improved bonding performance and strength, reduced volume shrinkage, good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

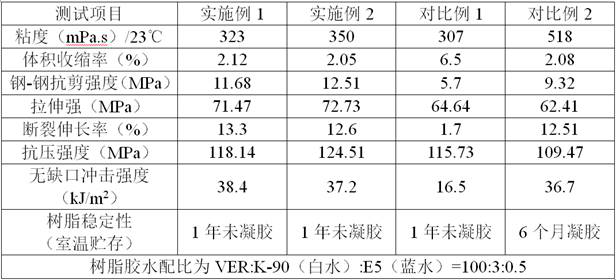

Examples

Embodiment 1

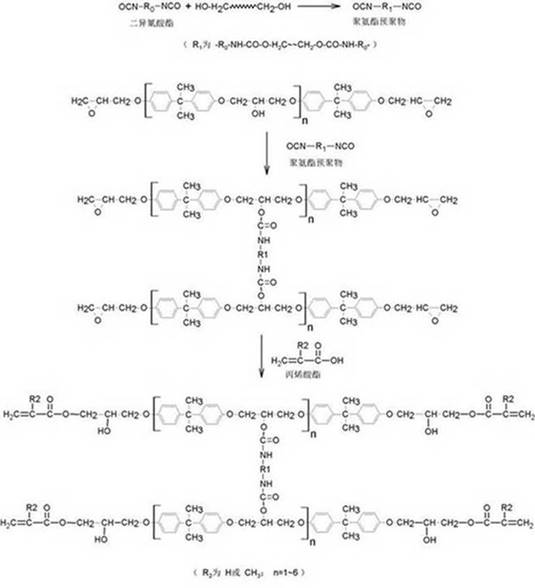

[0031] The preparation method of described a kind of high-strength high-toughness vinyl ester resin comprises the following steps:

[0032] Step 1: Polyurethane prepolymer synthesis steps, including:

[0033] Add 300g of polyether diol PPG2000 into the reaction flask and stir it, protect it with nitrogen, raise the temperature of the reaction flask to 80°C, then add 54.6g of TDI into the constant pressure dropping funnel, drop it at a speed of 2d / s, TDI drops After the addition, react at a constant temperature of 90°C, use the method of national standard HG / T 2409-92 to measure the -NCO content to 3.88%, stop the reaction when it reaches the theoretical value, and obtain polyurethane prepolymer (PUR) for later use.

[0034] Step 2: Synthesis steps of polyurethane prepolymer modified epoxy resin, including:

[0035] Add 454.6g of the polyurethane prepolymer (PUR) into the reaction bottle and stir it, protect it with nitrogen, raise the temperature of the reaction bottle to 90°...

Embodiment 2

[0039] The preparation method of described a kind of high-strength high-toughness vinyl ester resin comprises the following steps:

[0040] Step 1: Polyurethane prepolymer synthesis steps, including:

[0041] Add 200g of polyether diol PPG1000 into the reaction flask and stir it, protect it with nitrogen, raise the temperature of the reaction flask to 75°C, then add 71g of HDI into the constant pressure dropping funnel, drop it at a speed of 2d / s, and add HDI dropwise After completion, the reaction was carried out at a constant temperature of 85°C. The content of -NCO was measured to be 6.88% by the method of national standard HG / T 2409-92. When the theoretical value was reached, the reaction was stopped to obtain polyurethane prepolymer (PUR) for later use.

[0042] Step 2: Synthesis steps of polyurethane prepolymer modified epoxy resin, including:

[0043] Add 271g of the polyurethane prepolymer (PUR) into the reaction bottle and stir it, protect it with nitrogen, raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com