Implementation method of kerosene-based fuel for scramjet engine started by low Mach number

A technology of scram stamping and realization method, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of poor ignition performance, quality penalty, and deterioration of fuel combustion characteristics, and achieve stable physical form, simple operation, The effect of efficient regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In this embodiment, the liquid hydrocarbon fuel is configured according to the following proportions:

[0016] Step 1, utilizing to add RP-3 kerosene in the fuel tank that feeds nitrogen, the volume fraction (that is, the volume ratio accounting for the final product kerosene-based fuel, the same below) is 69%;

[0017] Step 2, adding 1-octene to the fuel tank with RP-3 kerosene added, the volume fraction is 10%.

[0018] Step 3: add activator borane triethylamine and 1-octene into the fuel tank to react, the volume fraction is 10%.

[0019] Step 4: Add di-tert-butyl peroxide, a free radical enhanced ignition agent, into the fuel tank, with a volume fraction of 10%.

[0020] Step 5. Add benzoquinone, a free radical stabilizer, into the above-mentioned fuel tank, with a volume fraction of 1%.

[0021] Step 6. The liquid in the fuel tank is uniformly mixed by means of magnetic stirring.

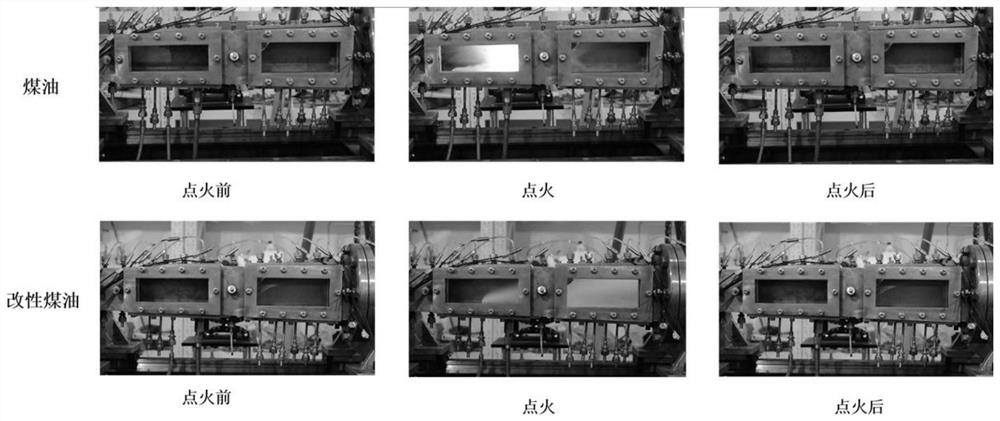

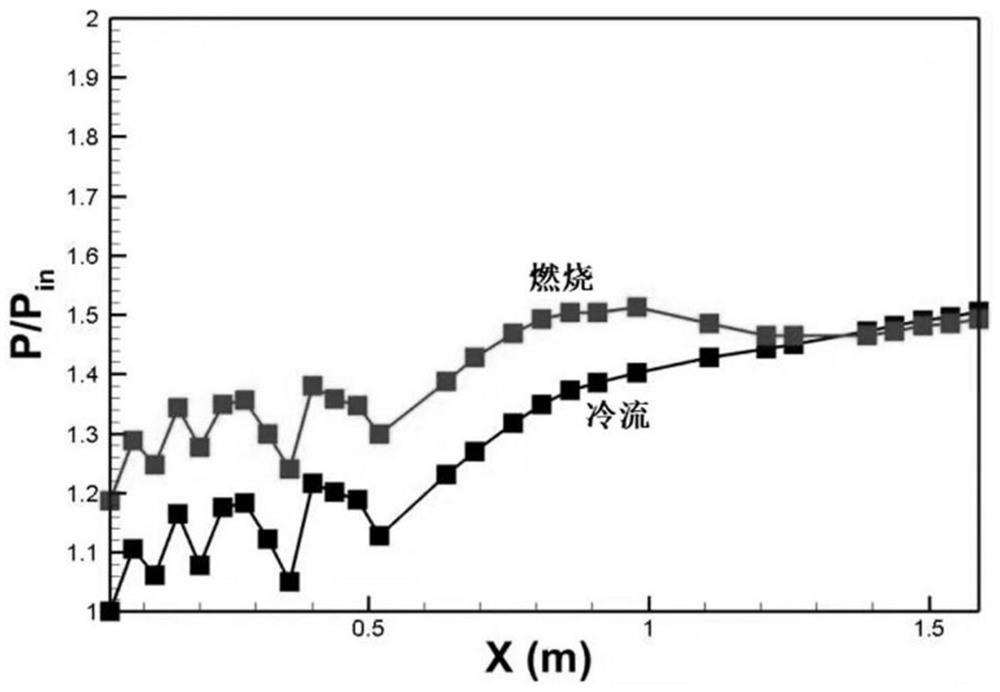

[0022] In this example, modified RP-3 kerosene was prepared by using a modified h...

Embodiment 2

[0024] In this embodiment, the modified liquid hydrocarbon fuel is configured according to the following proportions:

[0025] Step 1, utilize to add RP-3 kerosene in the fuel tank that feeds nitrogen, volume fraction is 63%;

[0026] Step 2, adding 1-octene to the fuel tank with RP-3 kerosene added, the volume fraction is 12%.

[0027] Step 3, add activator borane triethylamine and 1-octene into the above-mentioned fuel tank to react, the volume fraction is 12%.

[0028] Step 4, adding di-tert-butyl peroxide, a free radical enhanced ignition agent, into the above fuel tank, with a volume fraction of 12%.

[0029] Step 5. Add benzoquinone, a free radical stabilizer, into the above-mentioned fuel tank, with a volume fraction of 1%.

[0030] Step 6. The liquid in the fuel tank is uniformly mixed by means of magnetic stirring.

[0031] In this example, modified RP-3 kerosene was prepared by using a modified hydrocarbon fuel preparation device. The ignition characteristics of ...

Embodiment 3

[0033] In this embodiment, the modified liquid hydrocarbon fuel is configured according to the following proportions:

[0034] Step 1, utilize to add RP-3 kerosene in the fuel tank that feeds nitrogen, volume fraction is 54%;

[0035] Step 2, adding 1-octene to the fuel tank with RP-3 kerosene added, the volume fraction is 15%.

[0036] Step 3: adding activator borane triethylamine and 1-octene into the above-mentioned fuel tank to react, the volume fraction is 15%.

[0037] Step 4, adding di-tert-butyl peroxide, a free radical enhanced ignition agent, into the above-mentioned fuel tank, with a volume fraction of 15%.

[0038] Step 5. Add benzoquinone, a free radical stabilizer, into the above-mentioned fuel tank, with a volume fraction of 1%.

[0039] Step 6. The liquid in the fuel tank is uniformly mixed by means of magnetic stirring.

[0040] In this example, modified RP-3 kerosene was prepared by using a modified hydrocarbon fuel preparation device. The ignition charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com