A kind of manufacturing device of Gan single crystal

A technology for manufacturing devices and single crystals, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem that the large diameter of the GaN substrate cannot be widely used, etc., to increase the intuitiveness, increase the reaction contact area, and improve the The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

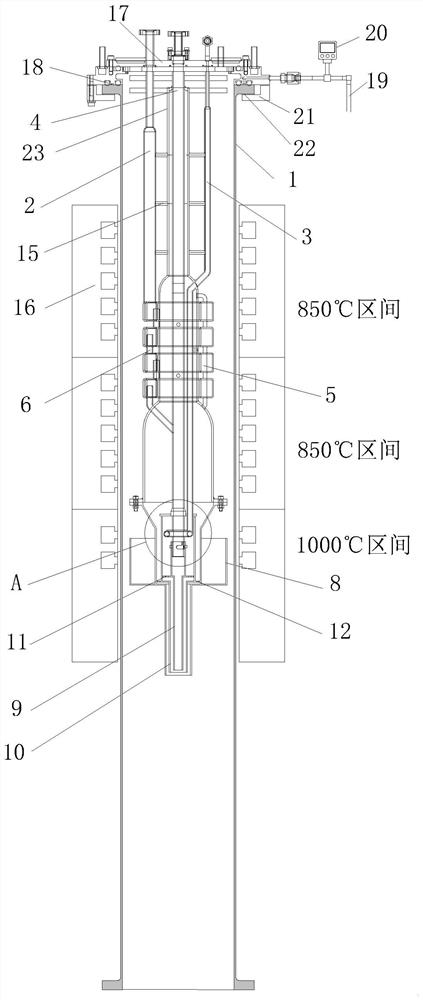

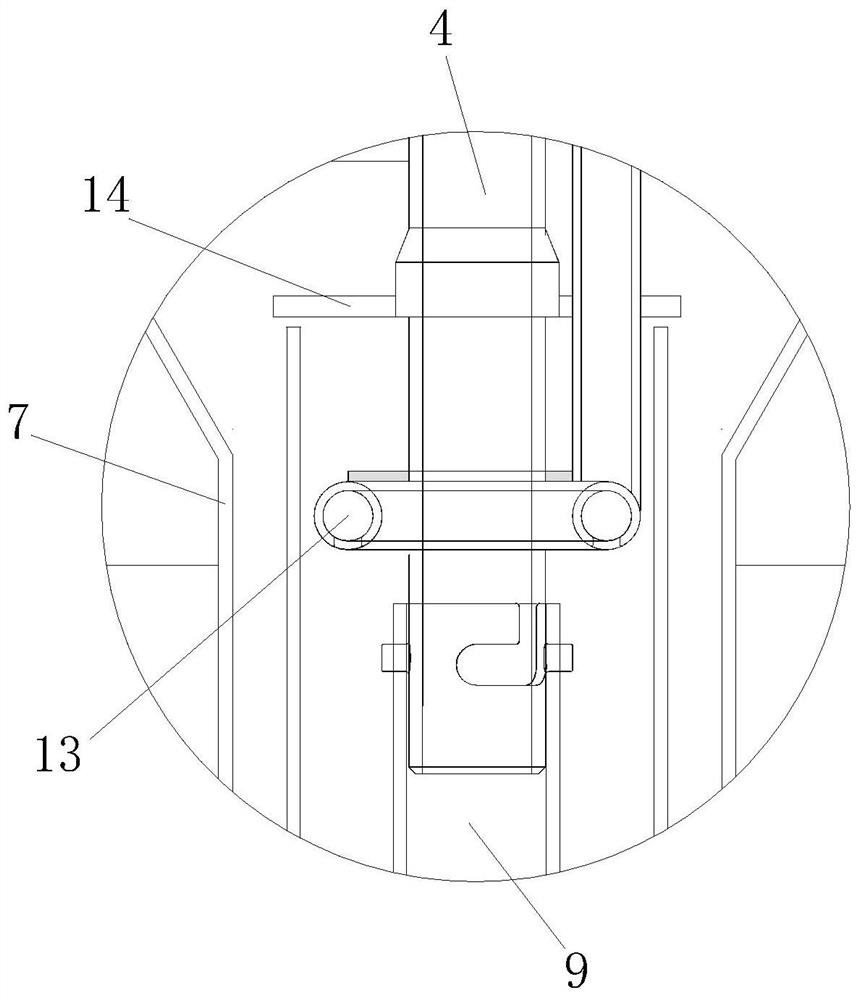

[0027] like Figure 1-2 As shown, the present invention provides a technical solution: a manufacturing apparatus of GaN single crystallization, including quartz-forming reactor 1, connecting flange 17 and separation flange 21, and the outer ring of quartz-reactor 1 have The high temperature electrical oven 16, the quartz-bearing tube 1 is provided with quartz production introduction tube 2, quartz air pipe 3, quartz-shaped content device 4, quartz extensive container 23, quartz-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com