Preparation method of superfine graphene anti-ultraviolet fabric

A technology of ultra-fine graphite and graphene, applied in the field of apparel fabrics, can solve the problems such as the decline of anti-ultraviolet performance, and achieve the effect of increasing the ability of absorbing ultraviolet rays, improving the ability of anti-ultraviolet, and strengthening the performance of absorbing and anti-ultraviolet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

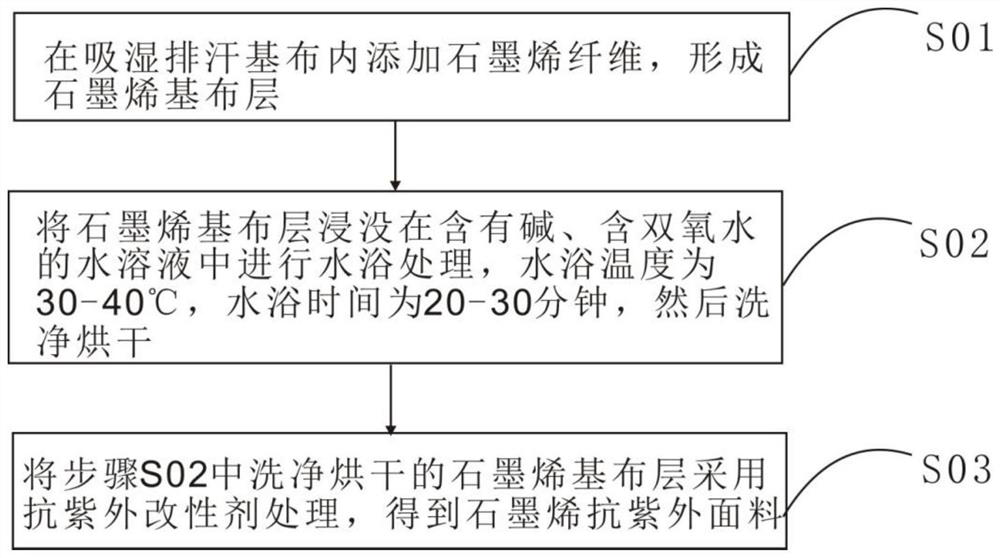

[0025] Such as figure 1 A kind of preparation method of shown ultrafine graphene anti-ultraviolet fabric, comprises the following steps:

[0026] S01, adding graphene fibers in the moisture-wicking base cloth to form a graphene base cloth layer;

[0027] In step S01, the moisture-absorbing and sweat-wicking base fabric is formed by mixing blended yarn, cotton fiber and polyester fiber, the weight ratio of the blended yarn in the moisture-wicking and sweat-wicking fabric layer is 25%, and the weight ratio of cotton fiber in the moisture-wicking and sweat-wicking base fabric is The ratio is 55%, and the polyester fiber accounts for 25% by weight in the moisture-absorbing and sweat-wicking base fabric; wherein, the blended yarn is made of cotton fiber, hemp fiber and modal fiber.

[0028] The graphene fiber in this embodiment is one or a combination of graphene nylon filaments, graphene nylon blended yarns, graphene polyester filaments, and graphene polyester blended yarns. The...

Embodiment 2

[0037] A kind of preparation method of ultrafine graphene anti-ultraviolet fabric shown in the present invention, comprises the following steps:

[0038] S01. Adding graphene fibers into the moisture-absorbing and sweat-wicking base fabric to form a graphene base fabric layer.

[0039] In step S01, the moisture-absorbing and sweat-wicking base fabric is formed by mixing blended yarn, cotton fiber and polyester fiber, the weight ratio of the blended yarn in the moisture-wicking and sweat-wicking fabric layer is 30%, and the weight of cotton fiber in the moisture-wicking and sweat-wicking base fabric is The ratio is 50%, and the polyester fiber accounts for 20% by weight in the moisture-absorbing and sweat-wicking base fabric; wherein, the blended yarn is made of cotton fiber, hemp fiber and modal fiber.

[0040] The graphene fiber in this embodiment is one or a combination of graphene nylon filaments, graphene nylon blended yarns, graphene polyester filaments, and graphene poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com