Hybrid bonding method and substrate for bonding

A hybrid bonding and bonding technology, which is applied in the fields of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of difficult sag control and high process requirements, and achieve the effect of reducing process difficulty and high fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of a hybrid bonding manufacturing method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

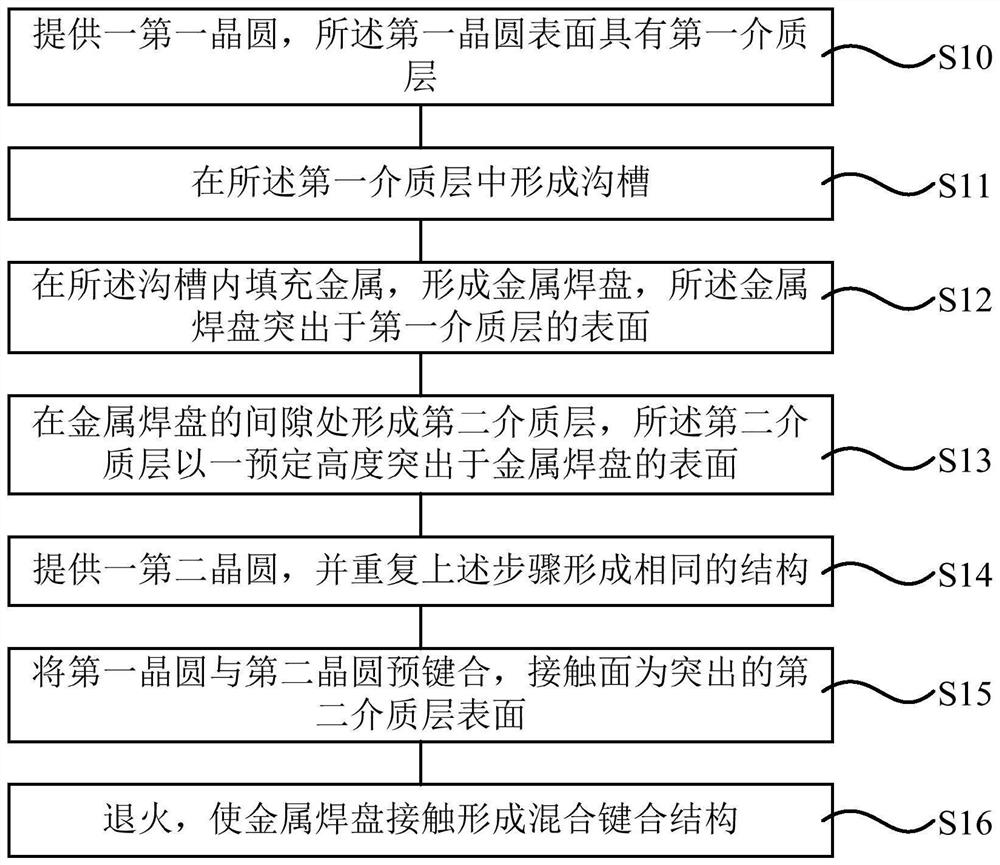

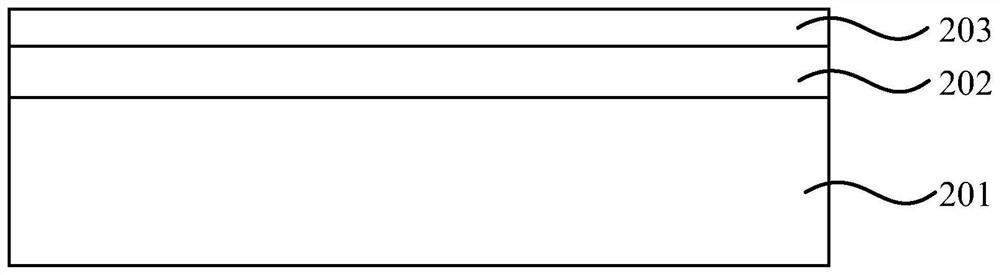

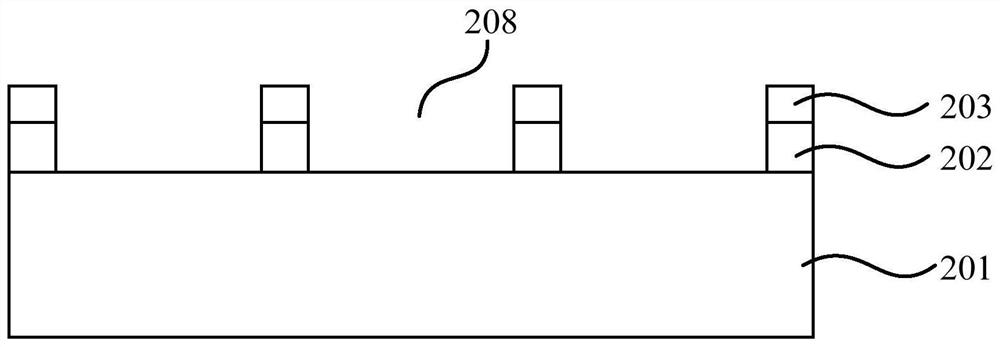

[0016] attached figure 1 Shown is a schematic diagram of the steps of a specific embodiment of the present invention, including: step S10, providing a first wafer, the surface of the first wafer has a first dielectric layer; step S11, in the first dielectric layer Forming a groove; step S12, filling the groove with metal to form a metal pad protruding from the surface of the first dielectric layer; step S13, forming a second dielectric layer at the gap between the metal pads , the second dielectric layer protrudes from the surface of the metal pad with a predetermined height; step S14, providing a second wafer, and repeating the above steps to form the same structure; step S15, combining the first wafer with the second wafer Round pre-bonding, the contact surface is the protruding surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com