A carbon-coated bam:eu2+ blue phosphor and preparation method thereof

A blue phosphor, carbon coating technology, used in chemical instruments and methods, luminescent materials, nanotechnology for materials and surface science, etc. Uniformity and other problems, to achieve the effect of convenient operation, improved thermal stability, and good reaction controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

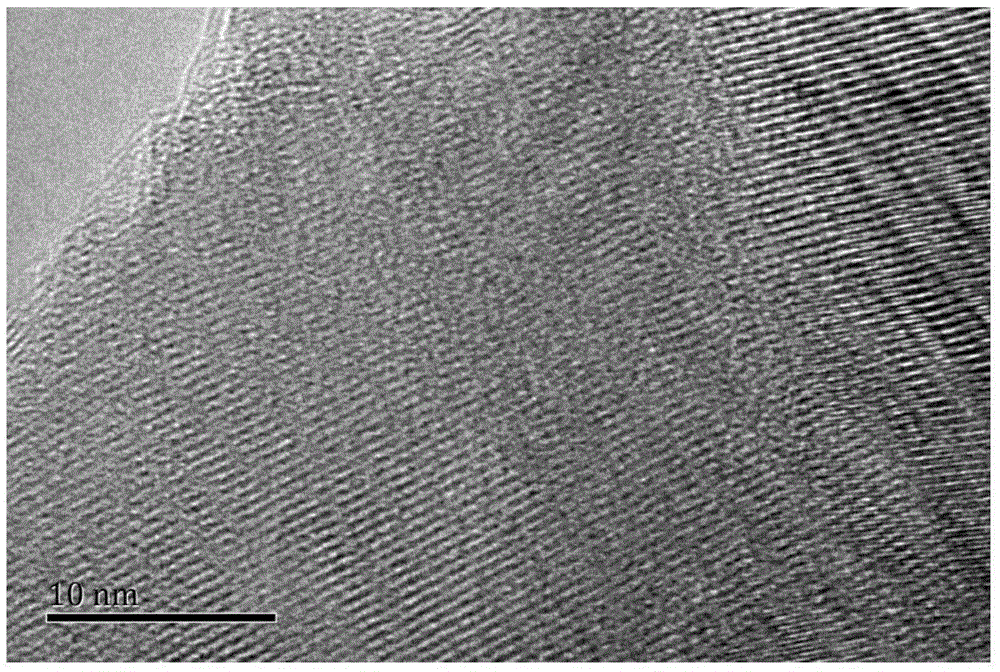

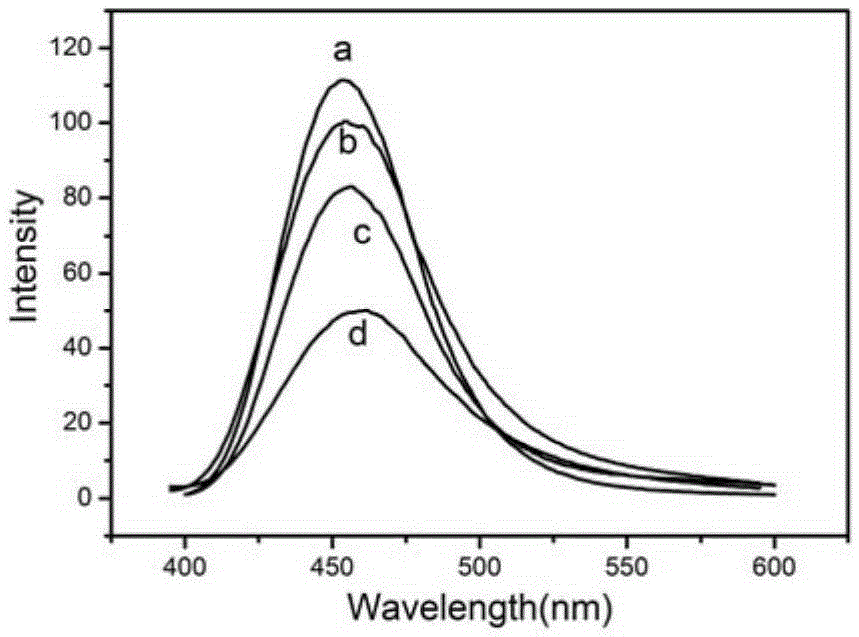

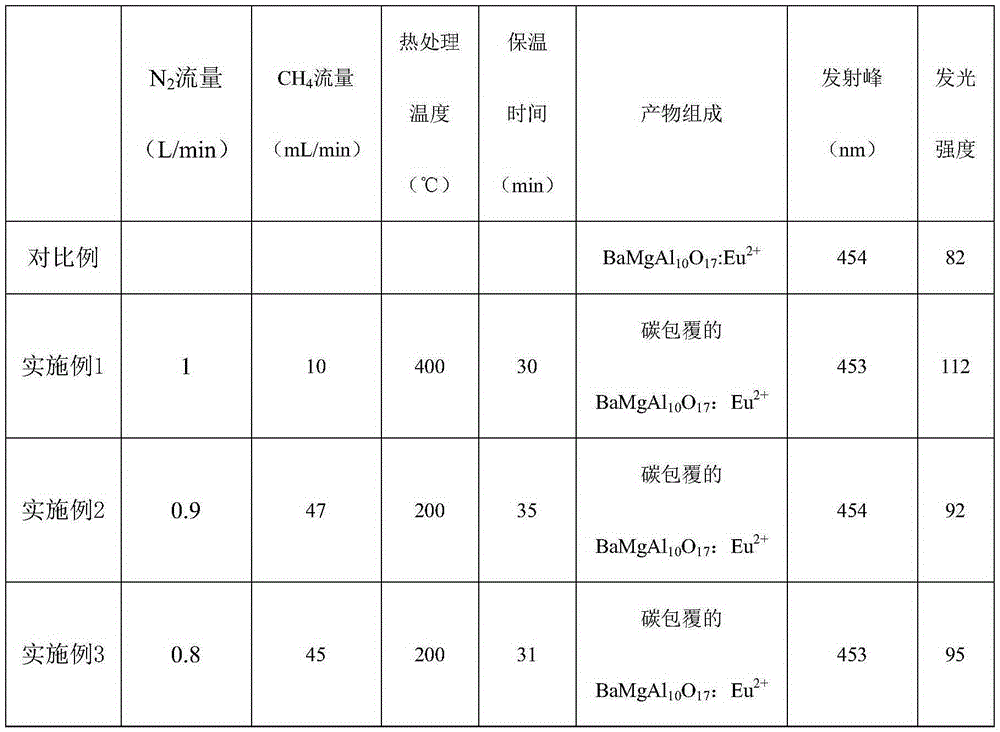

[0020] A carbon-coated BAM: Eu 2+ (BaMgAl 10 o 17 : Eu 2+ ) blue phosphor, characterized in that, in the BAM: Eu 2+ The surface of the blue fluorescent powder is coated with a carbon layer with a thickness of 1-20nm.

[0021] A carbon-coated BAM: Eu 2+ (BaMgAl 10 o 17 : Eu 2+ ) The preparation method of blue fluorescent powder, comprises the following steps:

[0022] Step 1: Add BAM:Eu 2+ (BaMgAl 10 o 17 : Eu 2+ ) The blue fluorescent powder is evenly spread on the quartz boat, and the thickness of the fluorescent powder is controlled to be 1-2 mm;

[0023] Step 2: Lay the above with BAM:Eu 2+ The quartz boat of the blue fluorescent powder is placed in a sintering furnace, evacuated to below 100Pa, and then nitrogen gas with a purity (in volume percentage) of 99.95% is introduced until the gas pressure is 1 standard atmospheric pressure, and the flow rate of the nitrogen gas is 0.1 ~1L / min;

[0024] Step 3: heat up to 200-900°C at a heating rate of 5°C / min, keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com