An ultra-dense cu(oh) 2 Preparation method and product of nanowire

A nanowire, C6H12N4 technology, applied in the field of preparation of ultra-dense Cu2 nanowires, can solve the problems of low contact points, long growth time, and influence on nanostructure performance, and achieve large specific surface area, high quality, and rich capillary channels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

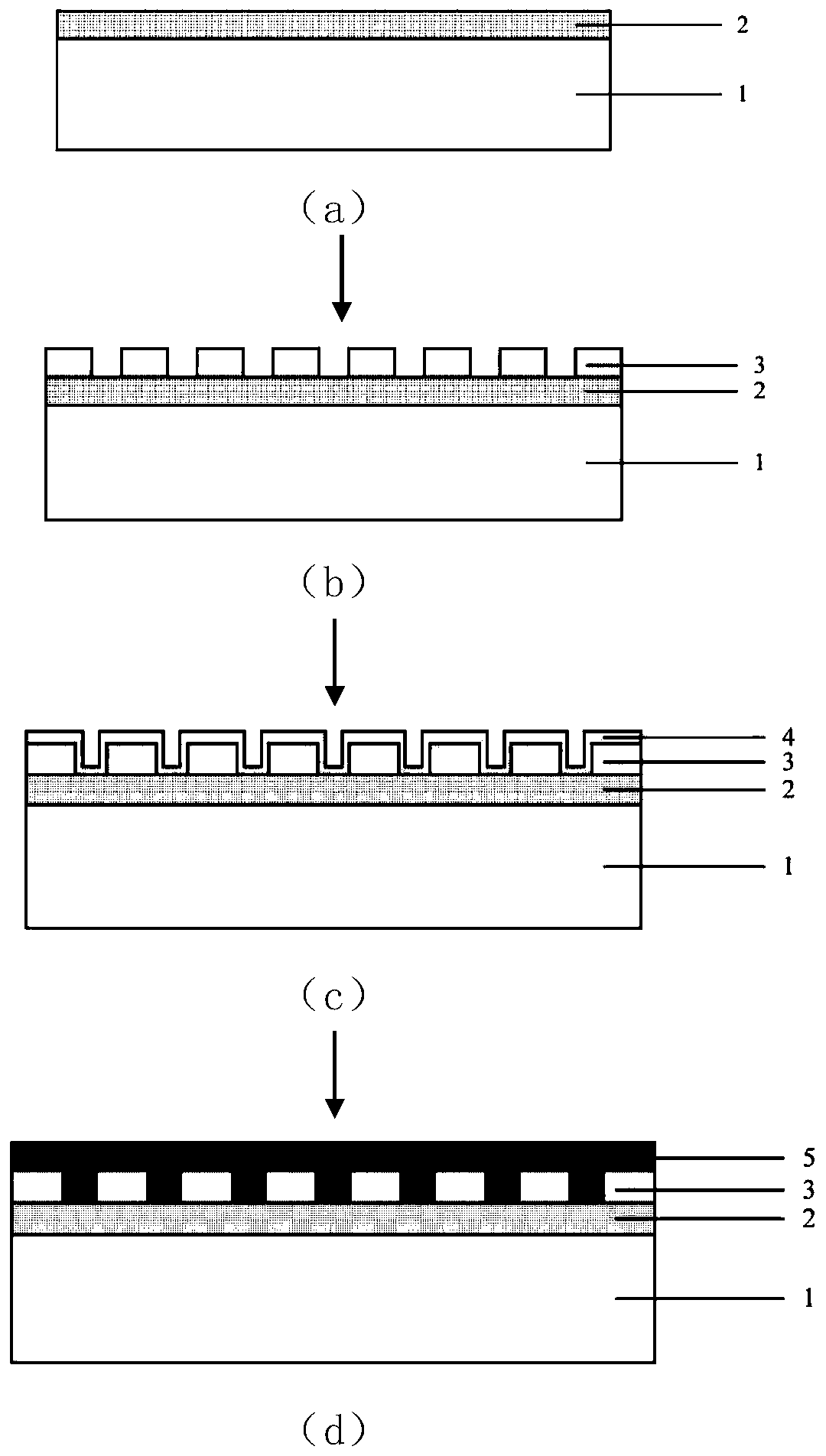

[0034] Embodiments of the present invention provide an ultra-dense Cu(OH) 2 A method for preparing nanowires, comprising the steps of:

[0035] (1) Preparation of the catalytic layer: a layer of ZnO seed layer with a thickness of ZnO is deposited on the substrate by magnetron sputtering, and then the substrate deposited with the ZnO seed layer is placed on Zn(NO 3 ) 2 6(H 2 O) and C 6 h 12 N 4 The mixed solution is used to grow ZnO nanorod catalytic layer, in which, Zn(NO 3 ) 2 6(H 2 O) and C 6 h 12 N 4 The molar mass concentration ratio is 1:5~5:1, the growth time is 10~60min, the sample is tilted upside down in the solution, and the solution temperature is room temperature;

[0036] (2 Preparation of seed layer: Deposit a Cu seed layer with a thickness of 0.025 μm to 1 μm on the substrate by magnetron sputtering for subsequent growth of superhydrophilic nanowires. Among them, the seed layer ZnO can only be used in radio frequency mode Sputtering is carried out, a...

Embodiment 1

[0041] A kind of ultra-dense Cu(OH) of the present embodiment 2 The preparation method of nanowire, the concrete steps of this method are as follows:

[0042] (1) Preparation of ZnO seed layer

[0043] A ZnO seed layer is deposited on the substrate 1 by sputtering, and a ZnO seed layer 2 with a thickness of 1 μm is deposited on the upper surface of the substrate by radio frequency magnetron sputtering with a power of 50 W and a vacuum of 0.1 Pa.

[0044] (2) Preparation of ZnO nanorods

[0045] Then in Zn(NO 3 ) 2 6(H 2 O) and C 6 h 12 N 4 ZnO nanorods were grown in mixed growth solution, Zn(NO 3 ) 2 6(H 2 O) and C 6 h 12 N 4 The molar mass concentration ratio is 5:1 to grow ZnO nanorods on the ZnO seed layer.

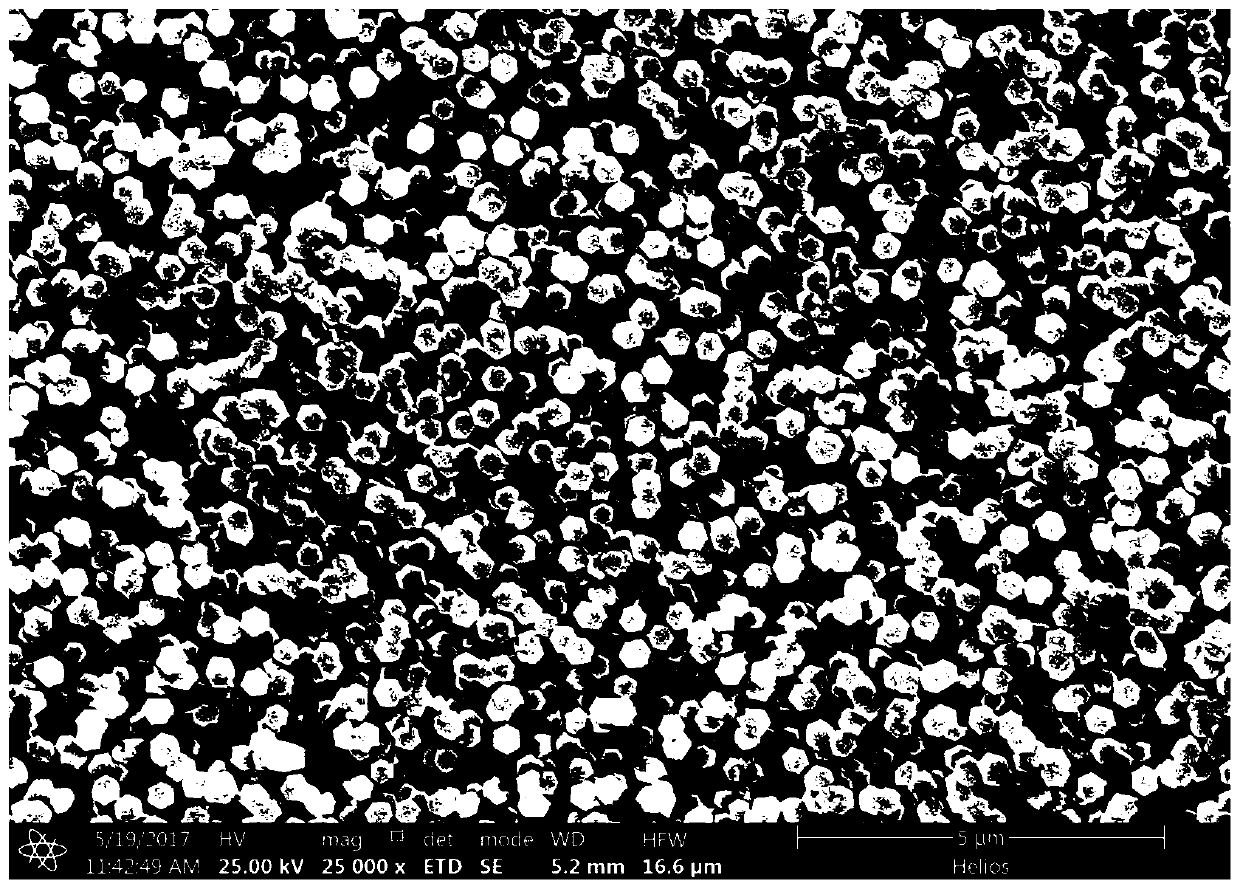

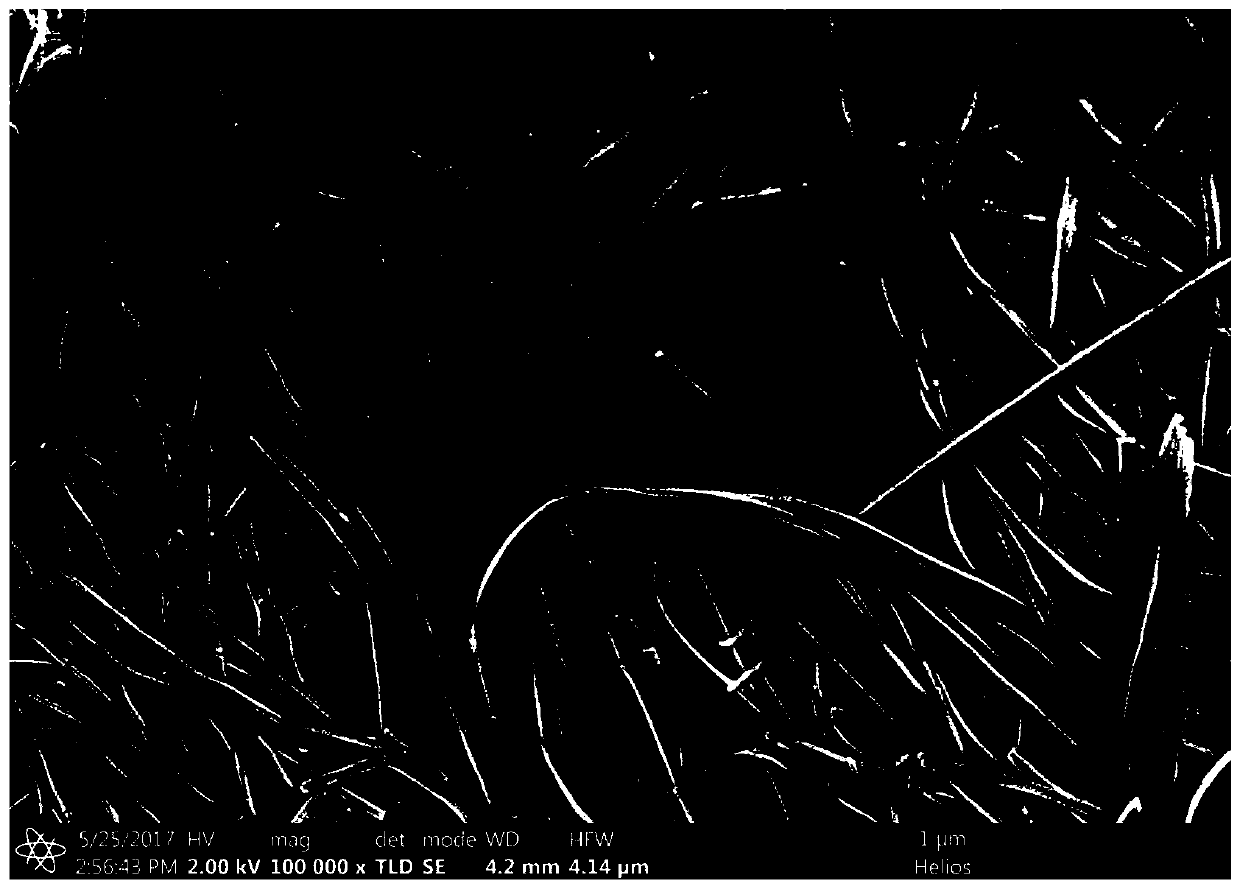

[0046] Such as figure 2 As shown, the scanning electron microscope (SEM) characterization diagram of the obtained ultra-dense super-hydrophilic ZnO nanorods.

[0047] (3) Preparation of Cu seed layer

[0048] Continue to deposit a Cu seed layer by spu...

Embodiment 2

[0053] A kind of ultra-dense Cu(OH) of the present embodiment 2 The preparation method of nanowire, the concrete steps of this method are as follows:

[0054] (1) Preparation of ZnO seed layer

[0055] A ZnO seed layer was deposited on the substrate 1 by sputtering, and a ZnO seed layer 2 with a thickness of 15 μm was deposited on the upper surface of the substrate by radio frequency magnetron sputtering with a power of 200 W and a vacuum of 0.1 Pa.

[0056] (2) Preparation of ZnO nanorods

[0057] Then in Zn(NO 3 ) 2 6(H 2 O) and C 6 h 12 N 4 ZnO nanorods were grown in mixed growth solution, Zn(NO 3 ) 2 6(H 2 O) and C 6 h 12 N 4 The molar mass concentration ratio is 1:1 to grow ZnO nanorods on the ZnO seed layer.

[0058] Such as Figure 4 As shown, the scanning electron microscope (SEM) characterization diagram of the obtained ultra-dense super-hydrophilic ZnO nanorods.

[0059] (3) Preparation of Cu seed layer

[0060] Continue to deposit a Cu seed layer by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com