A real-time elimination method of laser powder bed melting near-surface forming defects

A laser powder and laser remelting technology, applied in the field of additive manufacturing, can solve the problems of incomplete elimination of forming defects, increase of forming time and cost, etc., achieve sufficient response time, timely elimination of pore defects, and reduce surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

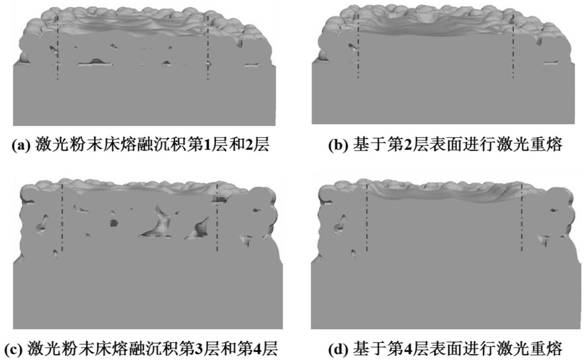

Embodiment 1

[0053] The present embodiment provides a real-time elimination method for laser powder bed melting near-surface forming defects, and the specific implementation steps are as follows:

[0054] Step 1: Monitor the distance h between the laser powder bed fusion forming defect and the surface of the deposition layer in real time through an external acquisition system;

[0055] Step 2: Determine the location of the defect according to the distance h between the forming defect and the surface of the deposition layer. The specific steps are as follows:

[0056] 1) When h>N thicknesses of deposited layers, laser remelting is carried out immediately, and the defect elimination of the deposited layer after remelting is judged. If the defect elimination meets the requirements, powder spreading and laser powder bed melting are performed; otherwise, optimization is performed. The remelting process performs laser remelting again until the defects are eliminated and the requirements are met;...

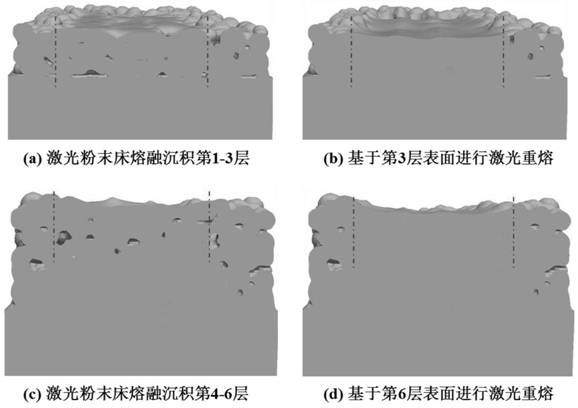

Embodiment 2

[0067] The present embodiment provides a real-time elimination method for laser powder bed melting near-surface forming defects, and the specific implementation steps are as follows:

[0068] Step 1: Monitor the distance h between the laser powder bed fusion forming defect and the surface of the deposition layer in real time through an external acquisition system;

[0069] Step 2: Determine the location of the defect according to the distance h between the forming defect and the surface of the deposition layer. The specific steps are as follows:

[0070] 1) When h>N thicknesses of deposited layers, laser remelting is carried out immediately, and the defect elimination of the deposited layer after remelting is judged. If the defect elimination meets the requirements, powder spreading and laser powder bed melting are performed; otherwise, optimization is performed. The remelting process performs laser remelting again until the defects are eliminated and the requirements are met;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com