Rubber composite material for cables as well as preparation method and application of rubber composite material

A composite material and rubber technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as poor compatibility of flame retardants with base rubber, and achieve chemical corrosion resistance, small thermal expansion coefficient, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

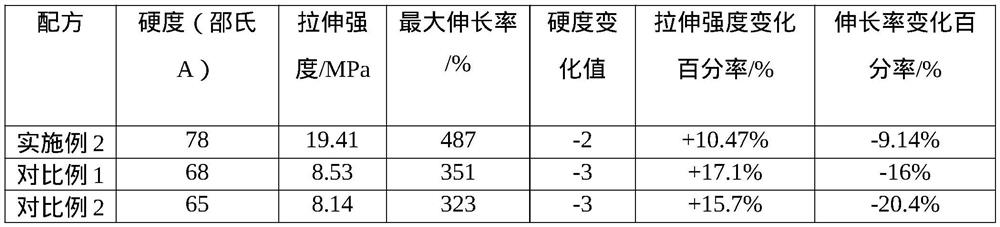

Examples

Embodiment 1

[0039] A preparation method for a rubber composite material for cables, comprising the steps of:

[0040] (1) Weighing: Weigh raw materials according to the following parts by weight: 100 parts of chlorosulfonated polyethylene; 20 parts of chlorosulfonated polyethylene reclaimed rubber; 60 parts of modified wollastonite; 15 parts of intumescent flame retardant; 10 parts of plastic; 40 parts of filling and reinforcing agent; 1 part of vulcanized material, spare;

[0041] (2) Preparation of modified wollastonite:

[0042] Weighing: Weigh raw materials according to the following parts by weight: 10 parts of wollastonite; 30 parts of polyethylene glycol; 20 parts of nitrile rubber, set aside;

[0043] Blend wollastonite and polyethylene glycol in absolute ethanol, soak for 40 minutes, dry to constant weight, rinse with absolute ethanol and 80°C pure water in turn, and then dry to constant weight to obtain polyethylene glycol Alcohol-coated wollastonite material;

[0044] Soak n...

Embodiment 2

[0050] A preparation method for a rubber composite material for cables, comprising the steps of:

[0051] (1) Weighing: Weigh raw materials according to the following parts by weight: 100 parts of chlorosulfonated polyethylene; 25 parts of chlorosulfonated polyethylene reclaimed rubber; 80 parts of modified wollastonite; 10 parts of intumescent flame retardant; 15 parts of plasticizer; 30 parts of filling and reinforcing agent; 5 parts of vulcanized material, spare;

[0052] (2) Preparation of modified wollastonite:

[0053] Weighing: Weigh raw materials according to the following parts by weight: 10 parts of wollastonite; 40 parts of polyethylene glycol; 30 parts of nitrile rubber, set aside;

[0054] Blend wollastonite and polyethylene glycol in absolute ethanol, soak for 45 minutes, dry to constant weight, rinse with absolute ethanol and 80°C pure water in turn, and then dry to constant weight to obtain polyethylene glycol Alcohol-coated wollastonite material;

[0055] N...

Embodiment 3

[0061] A preparation method for a rubber composite material for cables, comprising the steps of:

[0062] (1) Weighing: Weigh raw materials according to the following parts by weight: 100 parts of chlorosulfonated polyethylene; 30 parts of chlorosulfonated polyethylene reclaimed rubber; 95 parts of modified wollastonite; 5 parts of intumescent flame retardant; 25 parts of plastic; 20 parts of filling and reinforcing agent; 10 parts of vulcanized material, spare;

[0063] (2) Preparation of modified wollastonite:

[0064] Weighing: Weigh raw materials according to the following parts by weight: 10 parts of wollastonite; 40 parts of polyethylene glycol; 45 parts of nitrile rubber, set aside;

[0065] Blend wollastonite and polyethylene glycol in absolute ethanol, soak for 50 minutes, dry to constant weight, wash with absolute ethanol and 80°C pure water in turn, and then dry to constant weight to obtain polyethylene glycol Alcohol-coated wollastonite material;

[0066] Soak n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com