Preparation method of infant garment fabric

A fabric technology for infants and young children, applied in the field of preparation of infant clothing fabrics, can solve the problems of poor performance such as air permeability, moisture absorption, antistatic, etc., and achieve the effects of excellent antibacterial performance, smooth surface, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

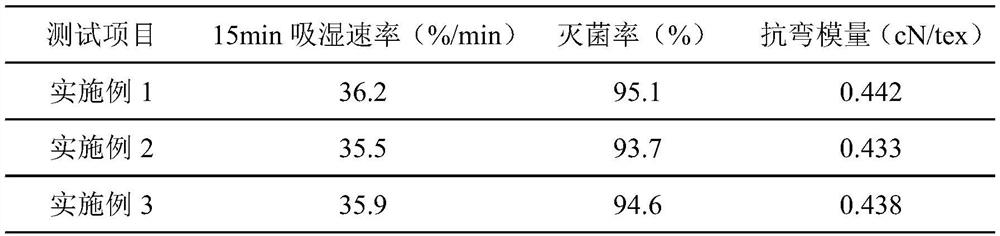

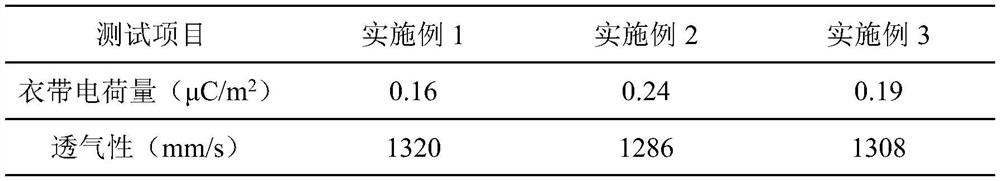

Examples

Embodiment 1

[0017] A preparation method for infant clothing fabrics, specifically comprising the following steps:

[0018] S1: Add β-N-acetylglucosaminidase to distilled water and stir to dissolve to form a 2.2% enzyme solution, then add dopamine and chitosan to the enzyme solution to obtain solution I.

[0019] S2: Soak cotton fibers and soybean fibers in solution I in step S1, then heat to 65°C and shake and stir for 3 to 4 hours, then remove and dry naturally, wash with distilled water for 3 times and dry to obtain modified Treated cotton fiber and soy fiber.

[0020] S3: The ascidian cellulose, castor oil and sodium alginate are fully mixed and then ground, and then passed through a 1000-mesh sieve to obtain a powder, and the powder is melt-spun, drawn, and shaped to obtain a fiber I.

[0021] S4: Then immerse the fiber I in step S3 in the solution I in step S1, then heat it to 65°C and shake and stir for 3 hours, then take it out and dry it naturally, wash it with distilled water fo...

Embodiment 2

[0025] A preparation method for infant clothing fabrics, specifically comprising the following steps:

[0026] S1: Add β-N-acetylglucosaminidase to distilled water and stir to dissolve to form a 2.6% enzyme solution, then add dopamine and chitosan to the enzyme solution to obtain solution I.

[0027] S2: Soak cotton fiber and soybean fiber in solution I in step S1, then heat to 70°C and shake and stir for 4 hours, then remove it and dry it naturally, wash it with distilled water for 5 times and then dry it to obtain the modified after treatment cotton fiber and soybean fiber.

[0028] S3: The ascidian cellulose, castor oil and sodium alginate are fully mixed and then ground, then passed through a 1200-mesh sieve to obtain a powder, and the powder is melt-spun, drawn, and shaped to obtain a fiber I.

[0029] S4: Then immerse the fiber I in step S3 in the solution I in step S1, then heat it to 70°C and shake and stir for 4 hours, then take it out and dry it naturally, wash it w...

Embodiment 3

[0033] A preparation method for infant clothing fabrics, specifically comprising the following steps:

[0034] S1: β-N-acetylglucosaminidase was added to distilled water and stirred to dissolve to form a 2.4% enzyme solution, then dopamine and chitosan were added to the enzyme solution to obtain solution I.

[0035] S2: Soak the cotton fiber and soybean fiber in the solution I in step S1, then heat it to 68°C for 3.5 hours with shaking and stirring, then take it out and dry it naturally, wash it with distilled water for 4 times and dry it to obtain the modified treatment After the cotton fiber and soybean fiber.

[0036] S3: The ascidian cellulose, castor oil and sodium alginate are fully mixed and then ground, then passed through a 1100-mesh sieve to obtain a powder, and the powder is melt-spun, drawn, and shaped to obtain a fiber I.

[0037] S4: Then immerse the fiber I in step S3 in the solution I in step S1, then heat it to 68°C and shake and stir for 4 hours, then take i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com