A kind of heat-sealing type smoke bopp film and preparation method thereof

A heat-sealing, cigarette technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of high static/dynamic friction factor, poor overall product performance, poor heat-sealing strength and low-temperature heat-sealing performance, etc. Achieve good low temperature heat sealing performance, improve quality stability and lasting antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] A heat-sealing BOPP film for cigarettes, the heat-sealing BOPP film for cigarettes is directly co-extruded with a three-layer structure of a surface layer, a core layer and an inner layer;

[0103] Wherein, the surface layer is made of the raw material comprising the following parts by weight:

[0104] Random copolymer polypropylene 38~45 parts,

[0105] 20-26 parts of propylene-ethylene copolymer,

[0106] 25-32 parts of ethylene-methyl acrylate copolymer,

[0107] 7.5-9 parts of modified crystal tourmaline powder,

[0108] 1.5-2 parts of 1,6-hexanediol diglycidyl ether,

[0109] 4.6 to 5.2 parts of a mixture of trimethylsiloxy amino-terminated polydimethylsiloxane and hydroxyl-terminated methyl-3,3,3-trifluoropropylpolysiloxane,

[0110] 3-4.5 parts of polytetrafluoroethylene modified polyethylene wax powder;

[0111] The core layer is made of raw materials including the following parts by weight:

[0112] Homopolypropylene 80~90 parts,

[0113] 12-17 parts of ...

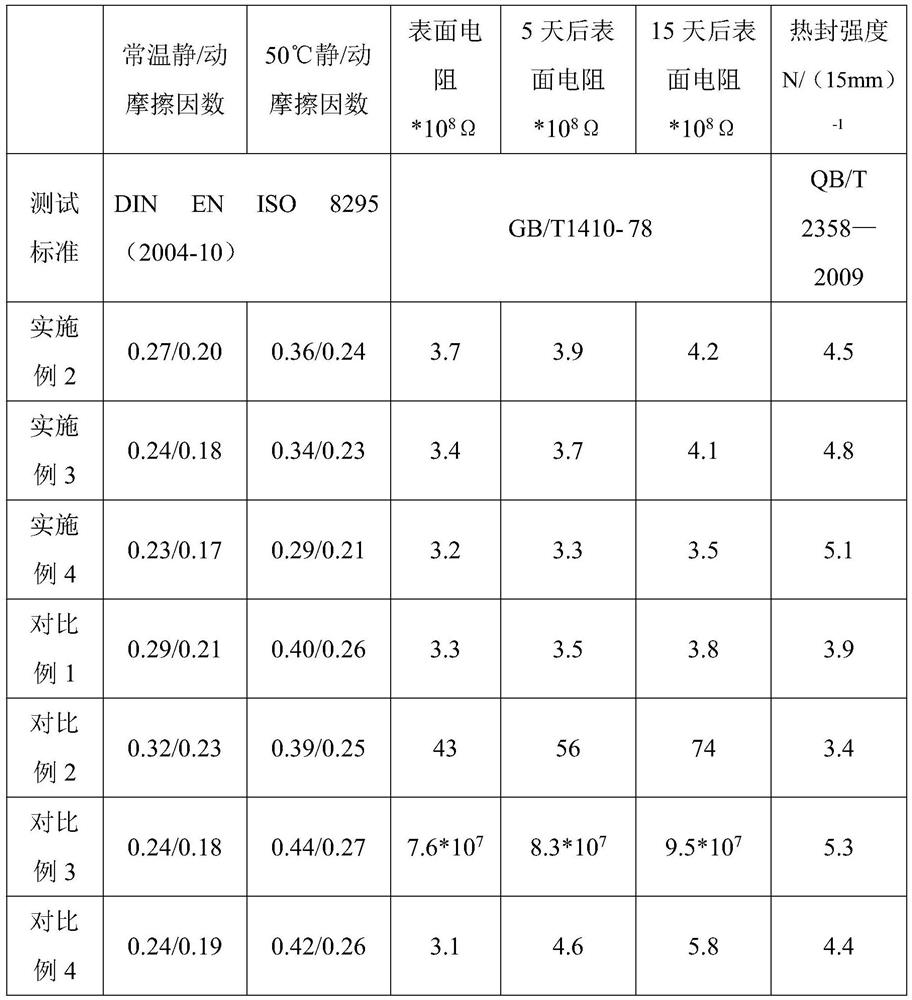

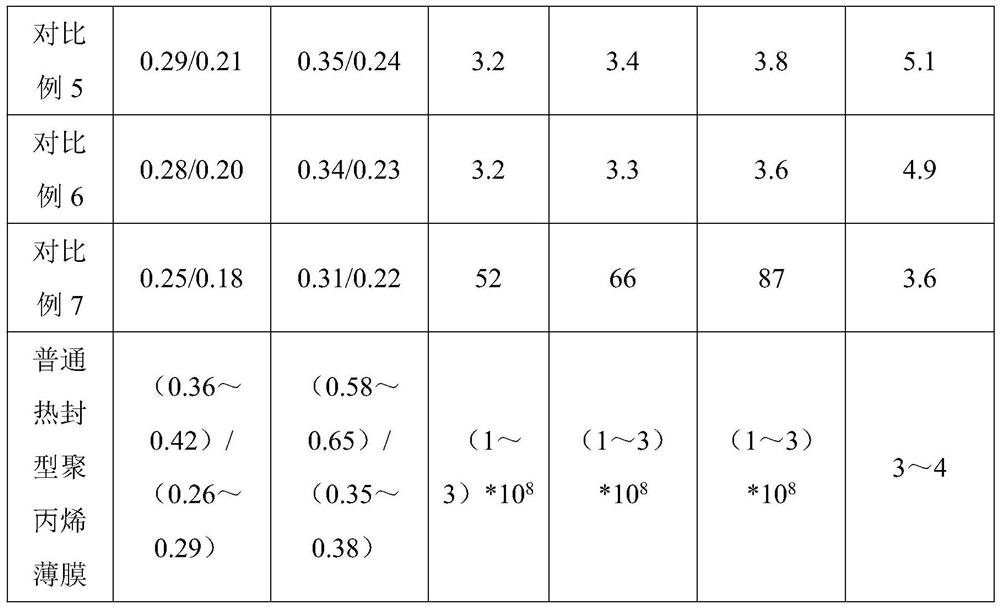

Embodiment 2

[0162] A heat-sealing BOPP film for cigarettes, the heat-sealing BOPP film for cigarettes is directly co-extruded with a three-layer structure of a surface layer, a core layer and an inner layer;

[0163] Wherein, the surface layer is made of the raw material comprising the following parts by weight:

[0164] 38 parts of random copolymerized polypropylene,

[0165] 20 parts of propylene-ethylene copolymer,

[0166] 25 parts of ethylene-methyl acrylate copolymer,

[0167] 7.5 parts of modified crystal tourmaline powder,

[0168] 1.5 parts of 1,6-hexanediol diglycidyl ether,

[0169] 4.6 parts of a mixture of trimethylsiloxy amino-terminated polydimethylsiloxane and hydroxyl-terminated methyl-3,3,3-trifluoropropylpolysiloxane,

[0170] 3 parts of polytetrafluoroethylene modified polyethylene wax powder;

[0171] The core layer is made of raw materials including the following parts by weight:

[0172] 80 parts of homopolypropylene,

[0173] 12 parts of propylene-ethylene c...

Embodiment 3

[0202] A heat-sealing BOPP film for cigarettes, the heat-sealing BOPP film for cigarettes is directly co-extruded with a three-layer structure of a surface layer, a core layer and an inner layer;

[0203] Wherein, the surface layer is made of the raw material comprising the following parts by weight:

[0204] 45 parts of random copolymerized polypropylene,

[0205] 26 parts of propylene-ethylene copolymer,

[0206] 32 parts of ethylene-methyl acrylate copolymer,

[0207] 9 parts of modified crystal tourmaline powder,

[0208] 2 parts of 1,6-hexanediol diglycidyl ether,

[0209] 5.2 parts of a mixture of trimethylsiloxy amino-terminated polydimethylsiloxane and hydroxyl-terminated methyl-3,3,3-trifluoropropylpolysiloxane,

[0210] 4.5 parts of polytetrafluoroethylene modified polyethylene wax powder;

[0211] The core layer is made of raw materials including the following parts by weight:

[0212] 90 parts of homopolypropylene,

[0213] 17 parts of propylene-ethylene cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com