Method for preparing silicon-calcium-barium-aluminum alloy from ore raw materials

A technology of aluminum alloy and silicon calcium barium, which is applied in the field of multi-component alloy preparation, can solve the problems of difficult deoxidation products, denaturation, and high cost of deoxidation, and achieve the effects of reducing the number of inclusions, enhancing deoxidation ability and desulfurization ability, and reducing the number of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

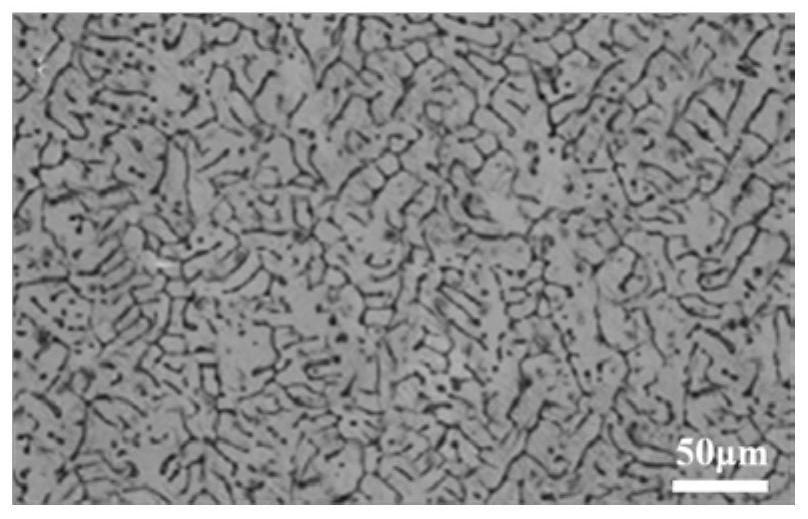

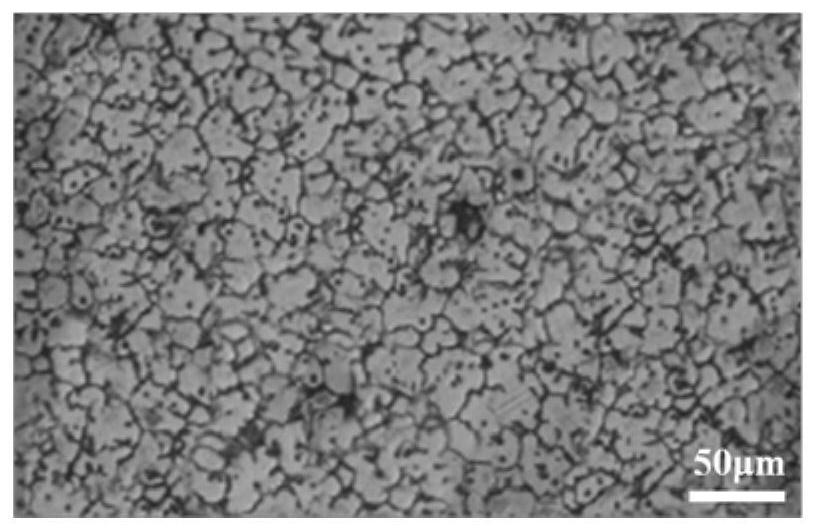

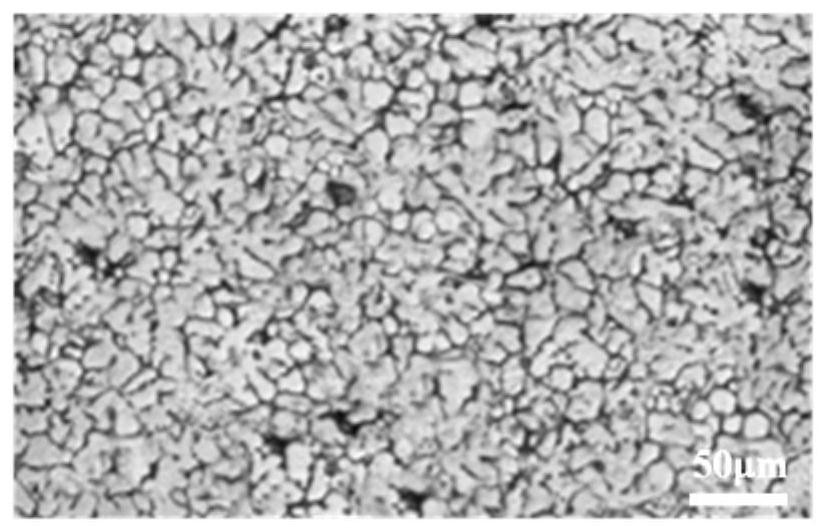

Image

Examples

Embodiment 1

[0030] The raw material components of a silicon-calcium-barium-aluminum alloy include 35% of silica, 9% of lime, 12.5% of barium ore, 6% of bauxite, 30% of semi-carbon, 3% of fluorite, 1.5% of stibnite, bismuth 0.5% ore, the balance of lead and zinc slag.

[0031] Among them, silica contains SiO 2 ≥98%, lime contains CaO≥88%, barium ore contains BaCO 3 ≥80%, bauxite containing Al 2 o 3 ≥80%, blue carbon containing C 固 ≥85%, fluorite contains CaF 2 ≥80%, stibnite containing Sb 2 S 3 ≥70%, bismuthite contains Bi 2 S 3 ≥80%, lead-zinc slag contains Fe≥68%.

[0032] The preparation of the above-mentioned silicon-calcium-barium-aluminum alloy includes:

[0033] S1: Clean and pulverize silica, lime, barium ore, bauxite, semi-coke, fluorspar, stibnite, bismuthnite and lead-zinc slag;

[0034] S2: Mix the crushed silica, lime, barium ore, bauxite, semi-coke, stibnite, and bismuthite in proportion, and add the mixture to the preheated submerged arc furnace for smelting in ...

Embodiment 2

[0038]A silicon-calcium-barium-aluminum alloy, the raw material components include 32% of silica, 11% of lime, 13% of barium ore, 5% of bauxite, 32% of semi-carbon, 2% of fluorite, 1.2% of stibnite, bismuth 0.2% ore, the balance of lead and zinc slag.

[0039] Among them, silica contains SiO 2 ≥98%, lime contains CaO≥88%, barium ore contains BaCO 3 ≥80%, bauxite containing Al 2 o 3 ≥80%, blue carbon containing C 固 ≥85%, fluorite contains CaF 2 ≥80%, stibnite containing Sb 2 S 3 ≥70%, bismuthite contains Bi 2 S 3 ≥80%, lead-zinc slag contains Fe≥68%.

[0040] The above-mentioned silicon-calcium-barium-aluminum alloy is prepared in the same manner as in Example 1.

[0041] The prepared silicon-calcium-barium-aluminum alloy contains: Si 54.1%, Ca 19.4%, Ba 17.9%, Al 6.8%, Sb 1.4%, Bi 0.2%, S 0.03%, P 0.02%, C 0.02% , Fe 0.13%.

Embodiment 3

[0043] A silicon-calcium-barium-aluminum alloy, the raw material components include: 35% silica, 9% lime, 12.5% barium ore, 6% bauxite, 30% semi-coke, 3% fluorite, 1.5% stibnite, lead-zinc Slag balance.

[0044] The above-mentioned silicon-calcium-barium-aluminum alloy is prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com