Sound-absorbing cotton processing system

A processing system, sound-absorbing cotton technology, applied in heating/cooling fabrics, cleaning with toothed tools, textiles and papermaking, etc., can solve the problem of fiber clogging the air supply duct inlet and other problems, avoid accumulation in piles, improve cooling and shaping effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

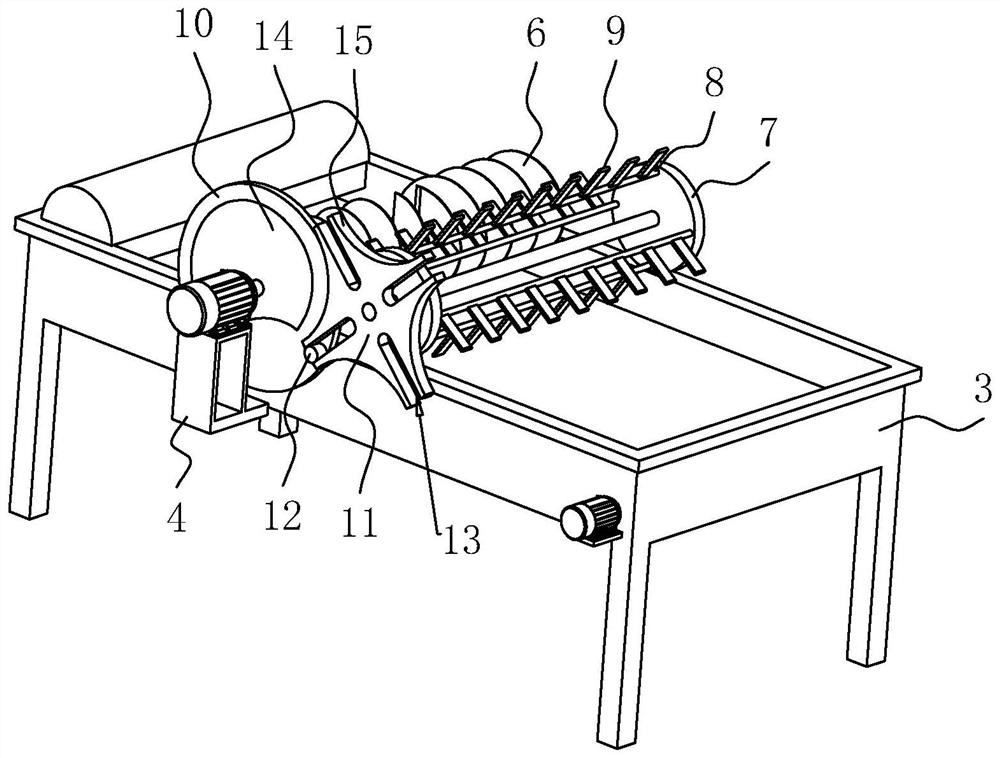

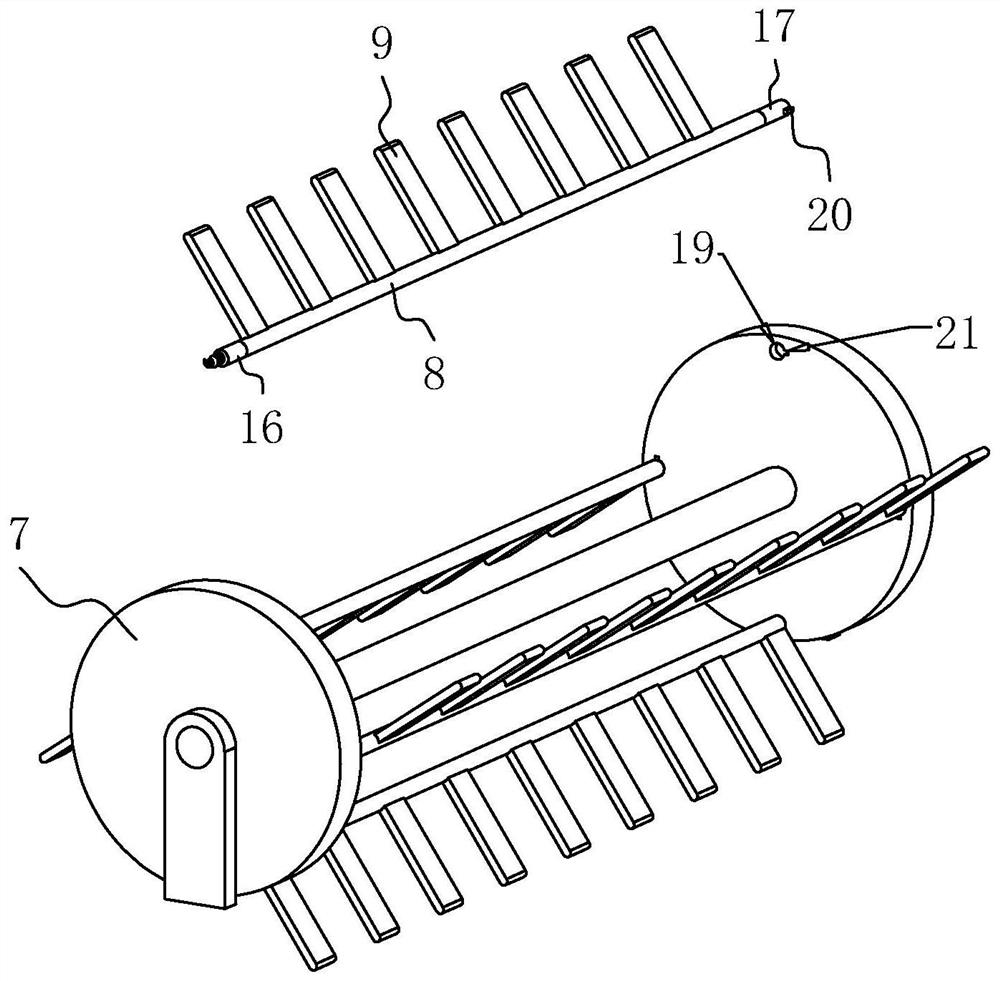

[0038] The following is attached Figure 1-6 The application is described in further detail.

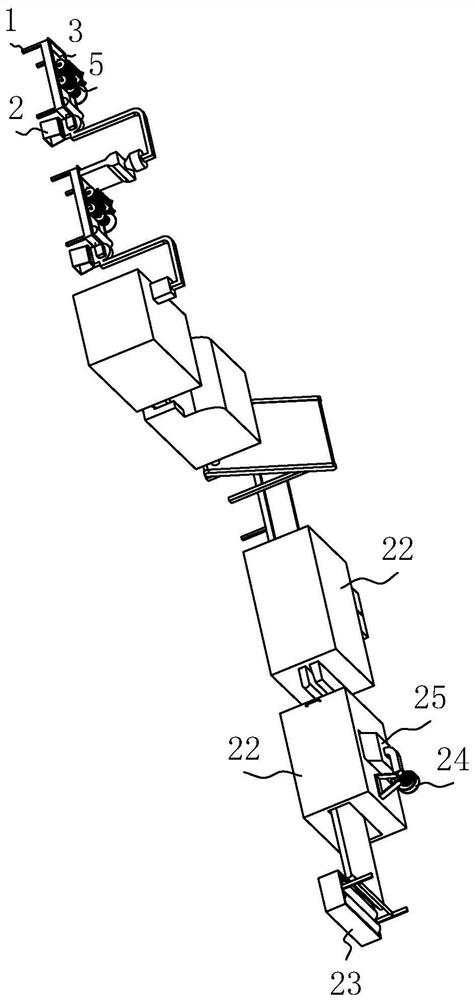

[0039] The embodiment of the present application discloses a sound-absorbing cotton processing system. refer to figure 1 A sound-absorbing cotton processing system includes a material preparation process, a treatment process, and a material receiving process arranged in sequence. The material preparation process includes a bale unpacking machine 1 and a cotton mixing machine 2. The bale unpacking machine 1 is used for weighing and distributing fibers. Cotton machines 2 are transported through the air delivery pipeline, and the cotton blender 2 is used to mix the fibers; the processing procedures include fine opener, cotton feeder, carding machine and web laying machine, and the rough opening of the cotton blender 2 The loose fibers are transported to the fine opening machine through the cotton feeding curtain and fully loosened to become the fine opening limit, and then sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com