Track planning method of concrete distribution robot based on Q learning

A technology of trajectory planning and robotics, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as difficulty in determining the optimal performance index, inability to cope with real-time changing factors on the construction site, and harsh construction conditions, etc., to achieve easy Change and test, avoid multi-objective optimization inverse calculation and data fitting process, and improve the effect of autonomy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

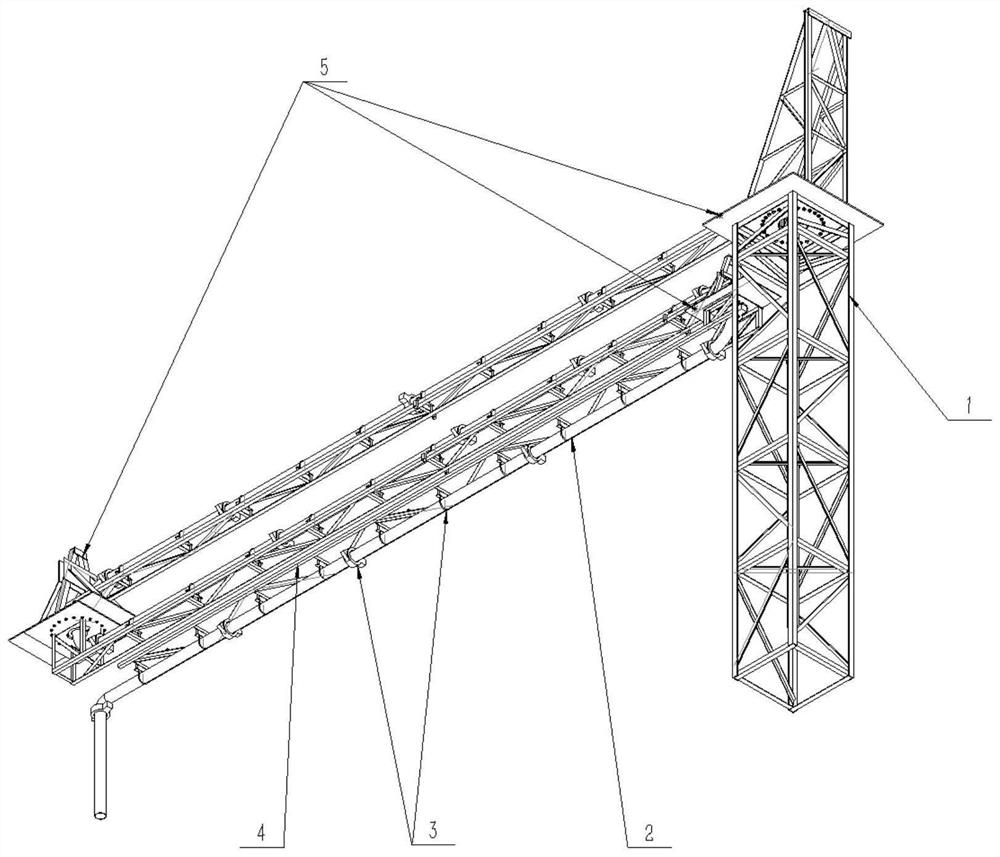

[0015] figure 1 It shows the overall structure of the designed intelligent redundant concrete placing robot, which is mainly composed of five modules, including column assembly (1), pipe assembly (2), pipe clamp (3), cantilever support (4), turntable assembly into (5). The design uses three rotary joints, and for the two-degree-of-freedom plane pouring, the design has one redundant degree of freedom.

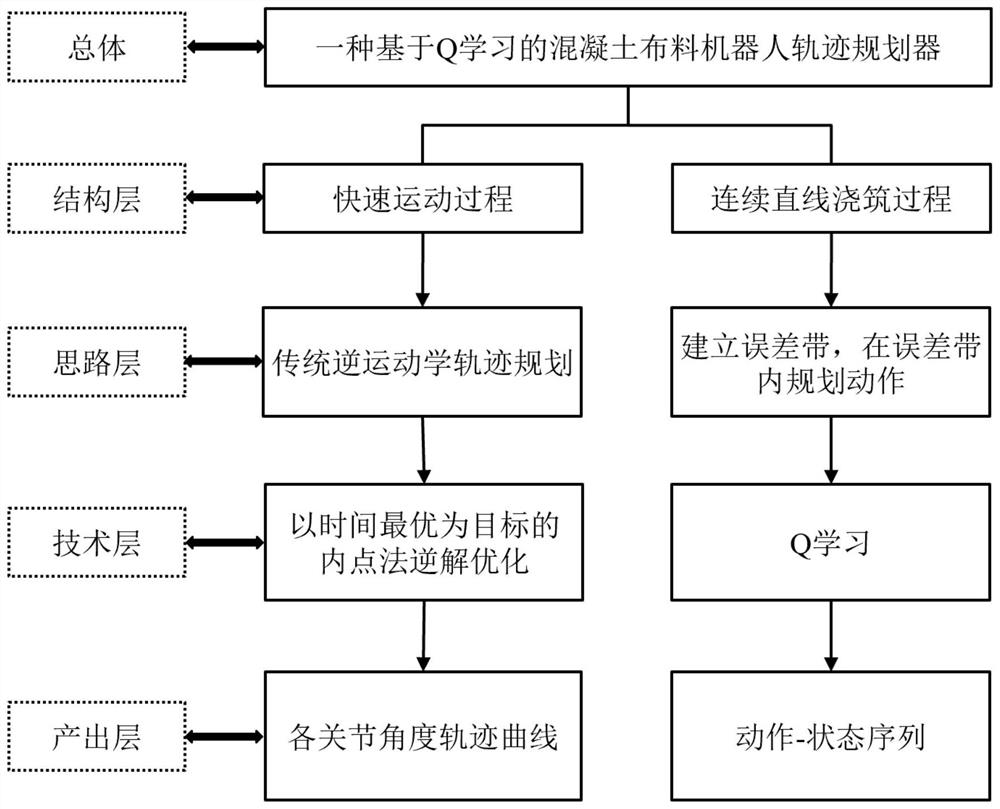

[0016] figure 2 It is the overall structure of the trajectory planner, including the planning method summary of the fast moving part and the continuous concrete pouring part.

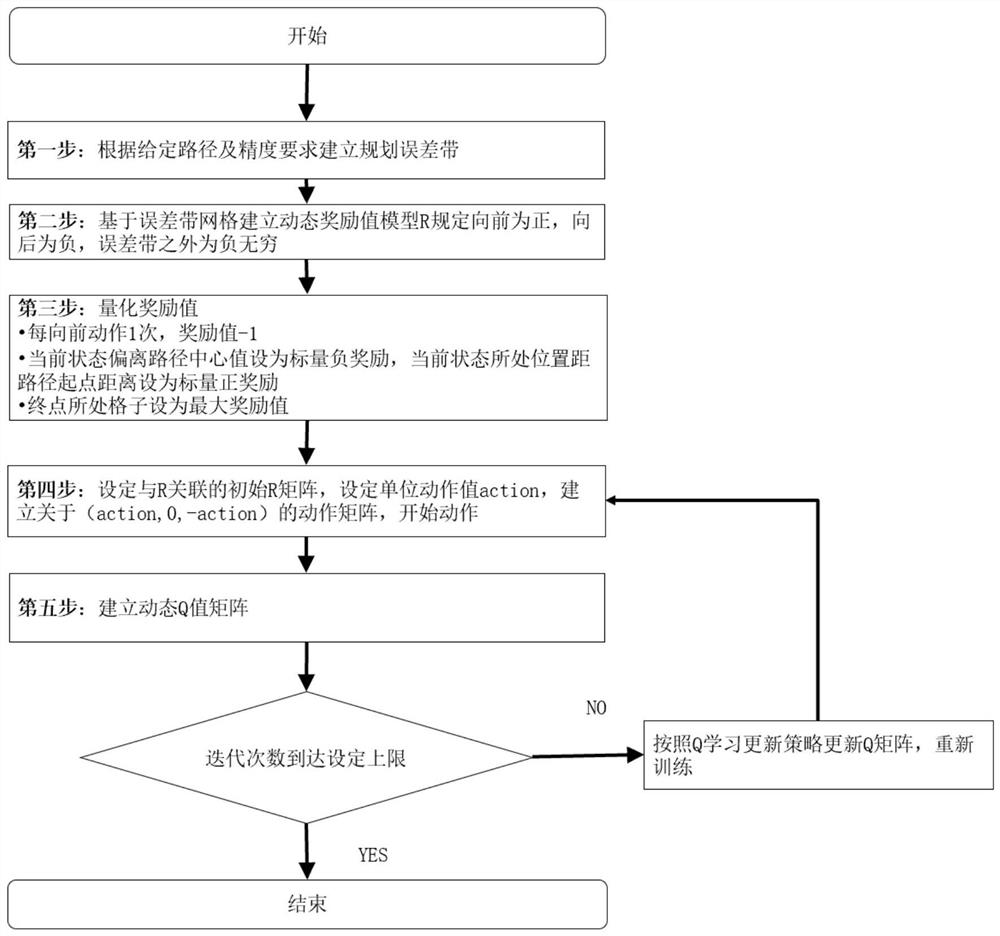

[0017] image 3 A detailed description of the thought layer and technical layer of the track planning part of the continuous pouring process of concrete, this part uses the Q learning method, image 3 Its application method and process are sorted out and summarized.

[0018] exist figure 2 In the paper, an overall design framework of trajectory planning for concrete cloth robot based on Q-learning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com