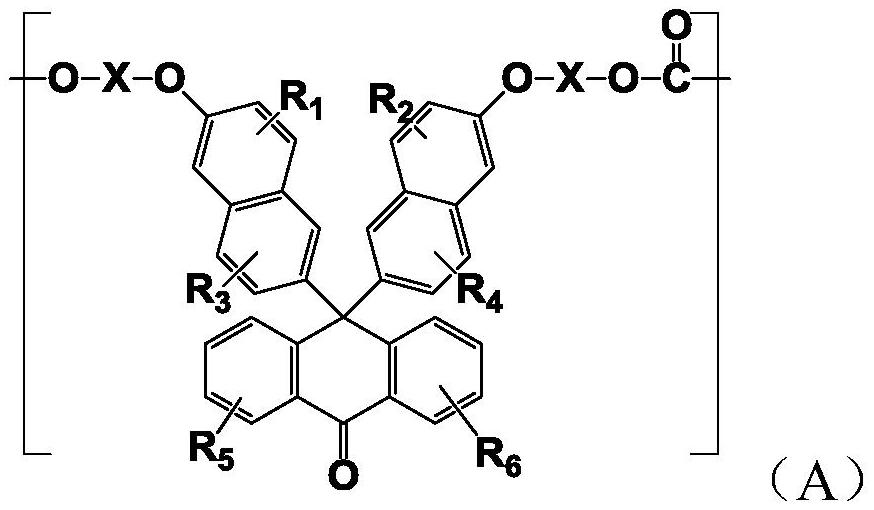

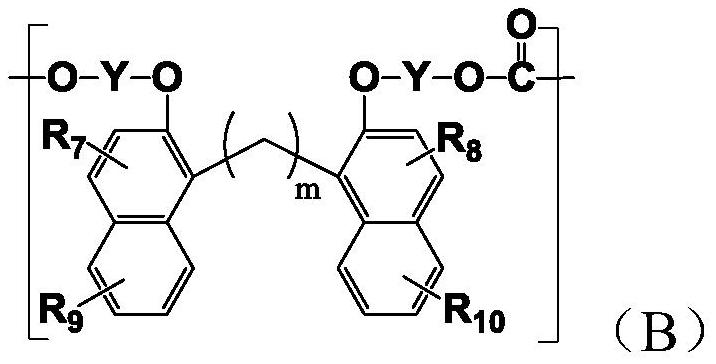

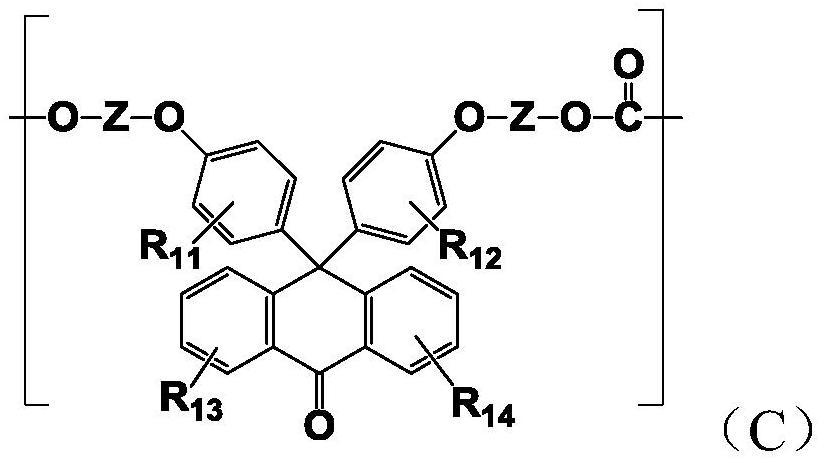

Polycarbonate resin for temperature-change-resistant optical component and preparation method and application of polycarbonate resin

A polycarbonate resin and optical component technology, applied in optical components, optics, instruments, etc., can solve the problems of polymer yellowing, affecting imaging effect, refractive index and light transmittance, etc., and achieve high temperature resistance. Stability, reduced lens weight, and promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 56.62g (0.1mol) BNEA, 20.35g (0.095mol) diphenyl carbonate, 0.012μg (0.5×10 -9 mol) lithium hydroxide, 0.219μg (0.5×10 -9 mol) cerium acetylacetonate was put into a 200ml four-neck flask equipped with a stirrer and a distillation device, replaced with nitrogen for 5 times, heated to 190°C under a nitrogen atmosphere of 101Kpa (A), started heating for 50 minutes and confirmed that the raw materials were completely dissolved, and then opened Stir, adjust the pressure to 20Kpa (A), and at the same time raise the temperature to 240°C at a rate of 30°C / hr. At this time, confirm that the phenol formed as a by-product begins to distill out, and maintain the reaction at 240°C for 180min, and then increase the temperature at 60°C / hr. The temperature was raised to 280°C at a certain speed, and after the temperature reached 280°C, the pressure was gradually reduced to 50 Pa (A) within 1 hour, and the reaction was stirred for 30 minutes under this condition to end the reaction. Af...

Embodiment 2

[0077] 28.31g (0.05mol) BNEA, 35.91g (0.05mol) BPNEA, 24.64g (0.115mol) diphenyl carbonate, 10.60μg (1×10 -7 mol) sodium carbonate is put into the 200ml four-necked flask that has agitator and distillation unit, except that, carry out the operation identical with embodiment 1, the polycarbonate physical parameter that obtains is as shown in table 1 (testing temperature 23 ℃). Show.

Embodiment 3

[0079] 35.91g (0.05mol) BPNEA, 27.01g (0.05mol) BHEPMBN, 21.42g (0.1mol) diphenyl carbonate, 4.37mg (1.0×10 -5 mol) cerium acetylacetonate is put into the 200ml four-necked flask that has stirrer and distillation unit, except that, carry out the operation identical with embodiment 1, the polycarbonate physical property parameter that obtains is as table 1 (test temperature 23 ℃) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com