Laser double-beam welding tool for outer side of aircraft panel

A technology for welding tooling and aircraft siding, applied to laser welding equipment, welding equipment, welding equipment, etc., can solve problems such as reduced production efficiency, skin damage, and improper assembly, so as to improve welding efficiency, increase pass rate, The effect of convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

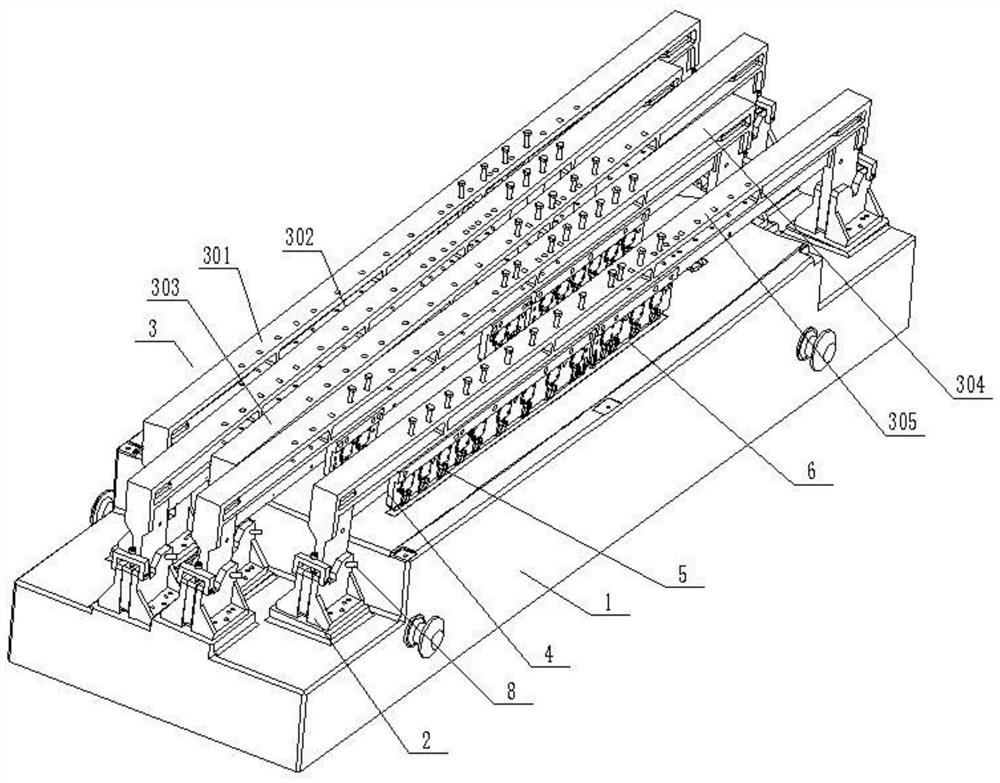

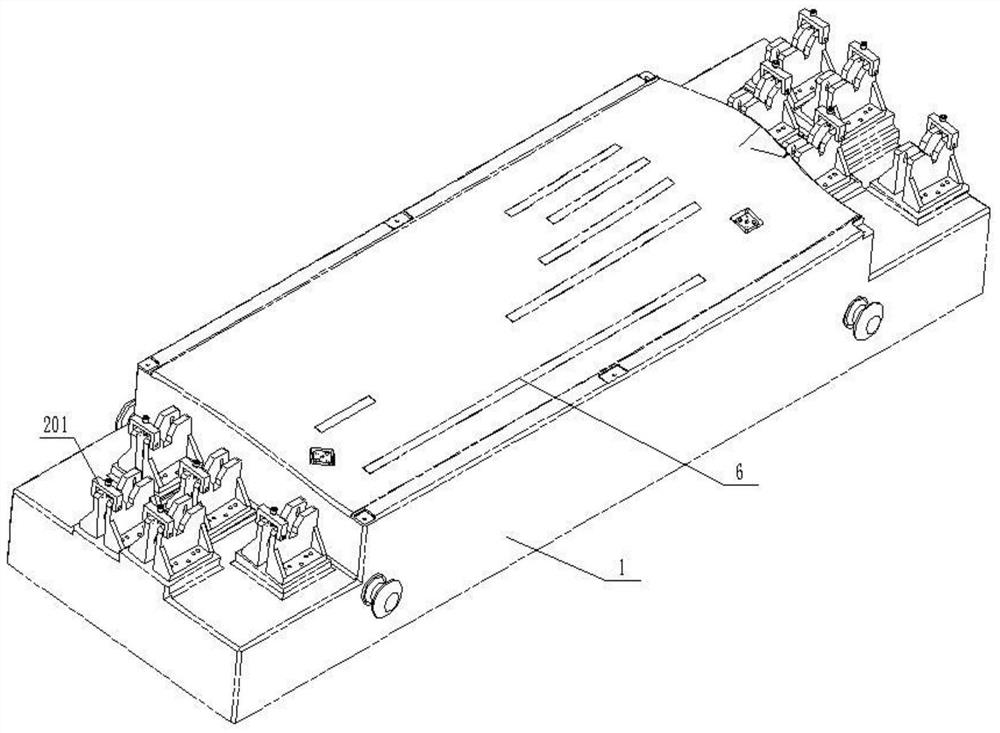

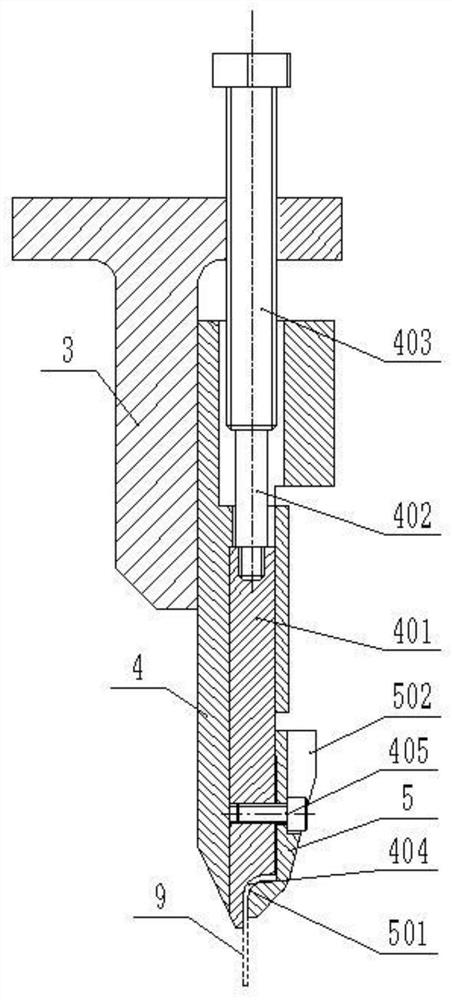

[0038] A laser double-beam welding tool for the outer side of an aircraft wall panel, such as Figure 1-Figure 9 As shown, it includes a base 1 and a support 2 provided at both ends of the base 1. At least one crossbeam 3 is fixed on the support 2, and each crossbeam 3 is provided with at least one set of clamping plates 4, and each set of clamping plates 4 is fixed There are a plurality of pressing plates 5 evenly arranged; the matching of the clamping plates 4 and the pressing plates 5 stipulates the workpiece on the beam 3, and the base 1 is provided with at least one set of copper sheets 6 for carrying the skin. The sheet 6 corresponds to the workpiece on the pallet 4, the bottom of the copper sheet 6 is provided with a pressure sensor 7; the beam 3 and the support 2 are provided with a position sensor, and the position sensor on the support 2 is used to detect The positional relationship between the crossbeam 3 and the support 2 , the position sensor on the crossbeam 3 is...

Embodiment 2

[0049] Take the outer tooling of the upper left wall panel as an example, such as Figure 1-Figure 9 shown;

[0050] The laser double-beam welding tooling of the present invention includes 5 sets of supports 2, each set of 2 supports 2, and each set of supports 2 is equipped with a crossbeam 3, that is, No. 1 crossbeam 301, No. 2 crossbeam 302, No. 3 crossbeam Beam 303 , Beam No. 4 304 and Beam No. 5 305 .

[0051] Among them, No. 1 crossbeam 301 is fixed with a group of clamping plates 4, and No. 1 long stringer is fixed on the clamping plates 4;

[0052] There is a long stringer positioned on the No. 2 beam, that is, the No. 2 stringer;

[0053] There is a long stringer positioned on the No. 3 beam, that is, the No. 3 stringer;

[0054] There are three girders positioned on No. 4 beam, namely, No. 4 girder, No. 5 girder, and No. 6 girder;

[0055] There are two girders positioned on No. 5 beam, namely, No. 7 girder and No. 8 girder;

[0056] Each girder corresponds to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com