A kind of low-phosphorus corrosion-inhibiting composite scale inhibitor and its application

A composite scale inhibitor and corrosion inhibition technology, applied in complex/solubilizer treatment, scale removal and water softening, natural water treatment, etc. Low volume and corrosion-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

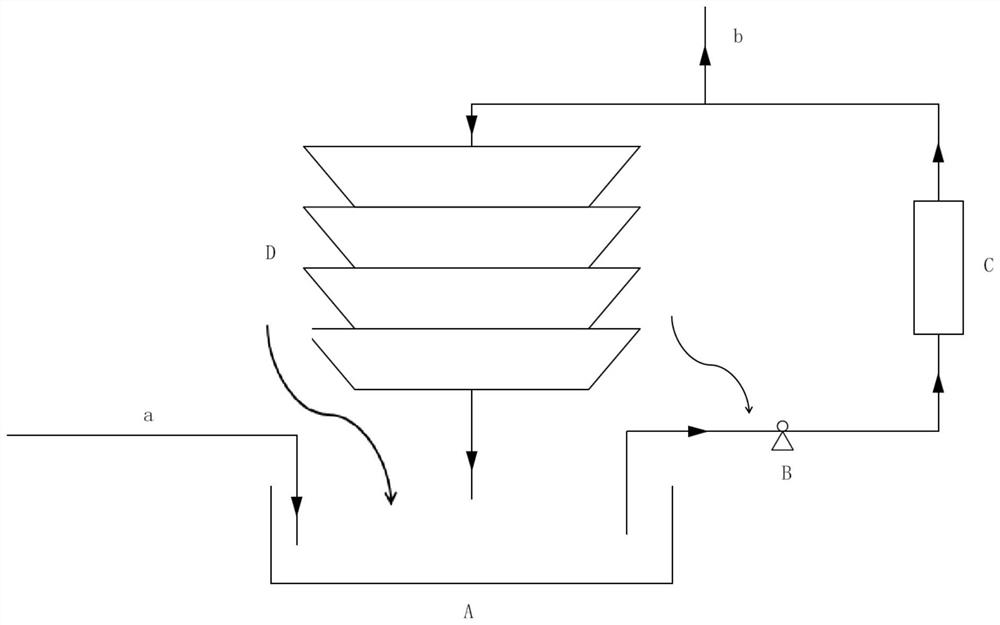

Image

Examples

Embodiment 1

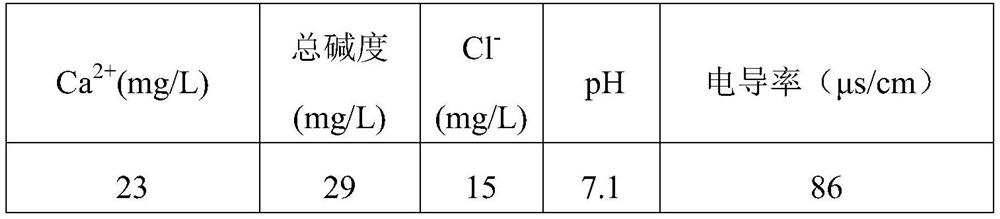

[0035] This example is used to illustrate the use method of the corrosion and scale inhibitor provided by the present invention.

[0036] Treatment: Add sodium polyepoxysuccinate, disodium hydroxyethylidene diphosphonate, nano calcium carbonate with an average particle size of 40nm, and zinc sulfate heptahydrate to the circulating water, so that the effective concentrations in the circulating water are 15mg / L, 1.5mg / L, 400mg / L, and 1mg / L (with Zn 2+ ), a dynamic simulation test was carried out.

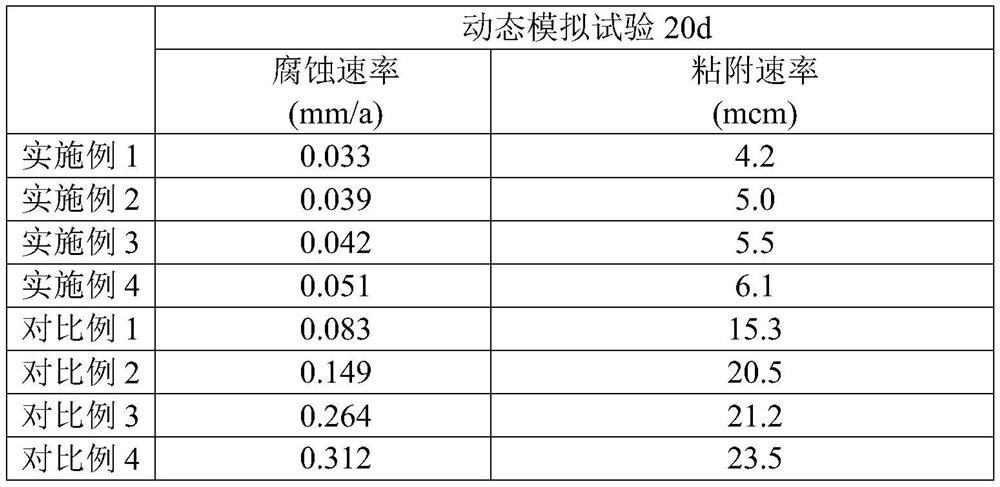

[0037] The simulation test results are shown in Table 2.

Embodiment 2

[0039] This example is used to illustrate the use method of the corrosion and scale inhibitor provided by the present invention.

[0040] Treatment: add sodium polyepoxysuccinate, disodium hydroxyethylidene diphosphonate, nano calcium carbonate with an average particle size of 20nm, and zinc sulfate heptahydrate to the circulating water, so that the effective concentrations in the circulating water are 10mg / L, 1.2mg / L, 300mg / L, and 1.5mg / L (with Zn 2+ ), a dynamic simulation test was carried out.

[0041] The simulation test results are shown in Table 2.

Embodiment 3

[0043] This example is used to illustrate the use method of the corrosion and scale inhibitor provided by the present invention.

[0044] Treatment: Add sodium polyepoxysuccinate, disodium hydroxyethylidene diphosphonate, nano-calcium carbonate with an average particle size of 10nm, and zinc sulfate heptahydrate to the circulating water, so that the effective concentrations in the circulating water are 2mg / L, 2mg / L, 100mg / L, and 2mg / L (with Zn 2+ ), a dynamic simulation test was carried out.

[0045] The simulation test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com