Method for protecting melt containing anhydrous magnesium chloride and/or anhydrous rare earth chloride

A technology of anhydrous magnesium chloride and rare earth chloride, which is applied in the field of protection of melts containing anhydrous magnesium chloride and/or anhydrous rare earth chloride, can solve problems such as high corrosion, melt hydrolysis, and good sealing performance, and achieve Low sealing requirements, inhibition of hydrolysis, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

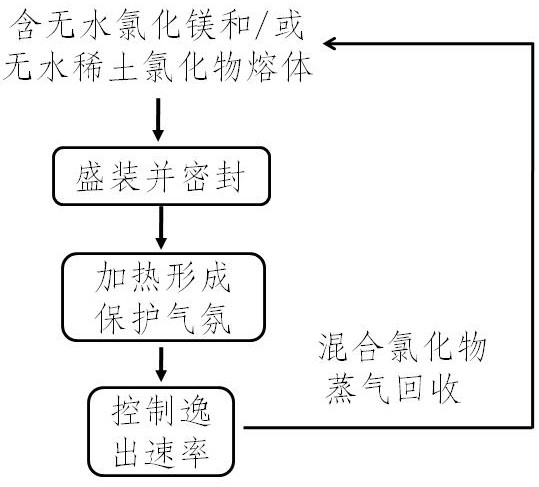

Image

Examples

Embodiment 1

[0047] The protected melt containing anhydrous magnesium chloride and anhydrous lanthanum chloride is placed in a container, and the melt composition is KCl (45wt.%)-NaCl (25wt.%)-CaCl 2 (15wt.%)-BaCl 2 (14.7wt.%)-MgCl 2 (0.1wt.%)-LaCl 3 (0.2wt.%). The total content of anhydrous magnesium chloride and anhydrous rare earth chloride in the melt is 0.3wt.%. The container is sealed and the sealed container has a steam inlet and a steam outlet. is 0.05m, and the volume ratio of the melt and its upper space is 105. Heat the melt at 500°C and keep it warm for 5 hours at this temperature, and control the steam escape rate of the sealed container to 3L / min, so that the total vapor partial pressure of anhydrous magnesium chloride and anhydrous rare earth chloride in the protective atmosphere accounts for The vapor partial pressure is 0.2%, and the total chloride vapor partial pressure accounts for 20% of the total pressure of the protective atmosphere. The escaped chlorinated mixtu...

Embodiment 2

[0051] The protected melt containing anhydrous magnesium chloride and anhydrous cerium chloride is placed in a container, and the melt composition is KCl (45wt.%)-NaCl (25wt.%)-CaCl 2 (15wt.%)-BaCl 2 (14.5wt.%)-MgCl 2 (0.4wt.%)-CeCl 3 (0.1wt.%). The total content of anhydrous magnesium chloride and anhydrous rare earth chloride in the melt is 0.5wt.%, the container is sealed and the sealed container has a steam outlet, the gas pressure in the sealed container is equal to 1.0atm, and the height of the upper space of the melt is 0.1m , the volume ratio of the melt to its upper space is 95. Heat the melt at 700°C and keep it warm at this temperature for 5 hours, control the steam escape rate of the sealed container to 5L / min and the gas volume and composition of the steam inlet, so that the anhydrous magnesium chloride and anhydrous rare earth chloride vapor in the protective atmosphere The sum of the partial pressures accounts for 1.0% of the partial pressure of the total ch...

Embodiment 3

[0055] The protected melt containing anhydrous magnesium chloride and anhydrous praseodymium chloride is placed in a container, and the melt composition is KCl (45wt.%)-NaCl (25wt.%)-CaCl 2 (15wt.%)-BaCl 2 (10.0wt.%)-MgCl 2 (4.0wt.%)-PrCl 3(1.0wt.%). The total content of anhydrous magnesium chloride and anhydrous rare earth chloride in the melt is 5.0wt.%. The container is sealed and the sealed container has a steam outlet and a steam inlet. The gas pressure in the sealed container is equal to 2.0 atm, and the height of the upper space of the melt is is 3m, and the volume ratio of the melt and its upper space is 0.5. Heat the melt at 1100°C and keep it warm at this temperature for 10 hours, control the steam escape rate of the sealed container to 10L / min and the gas volume and composition of the steam inlet, so that the anhydrous magnesium chloride and anhydrous rare earth chloride vapor in the protective atmosphere The sum of the partial pressures accounts for 10% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com